5 - Removal and Re-installation

ExpressCard 2000 / ExpressCard 3000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 262 of 356 (

D99875607-91

)

5.27

How to Remove / Re-install the Tipper Heater

High-level Steps

Prepare device for removing / reinstalling modules

Remove the tipper heater

Re-install the tipper heater

Set the device to the correct temperature

Approximate time to remove: 15 minutes plus any sub-procedures

Approximate time to re-install: 15 minutes plus any sub-procedures

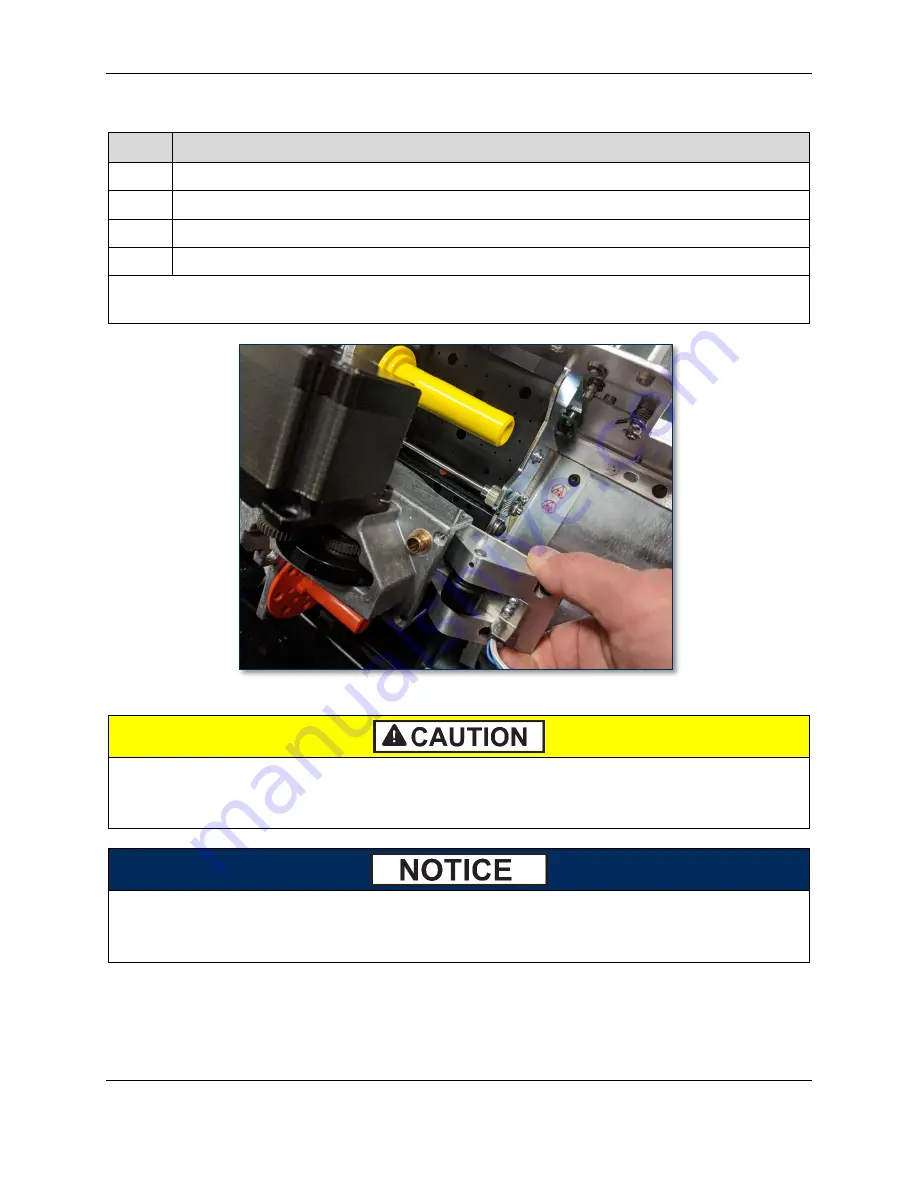

Figure 5-117 - Tipper Heater

The tipper heater is hot and can burn your skin! Make sure the device has been turned

off, or the heater has been turned off and no cards have been produced, for at least 10

minutes to allow adequate cooling time before touching the tipper heater.

Some of the modules inside the ExpressCard you are servicing may look different from

the photos in this procedure. However, the steps of the procedure are the same, and are

unrelated to / unaffected by the appearance of the modules.

The heater in the tipper module fuses the tipper foil to the embossed characters on cards. It is a

replaceable part that wears out over time and must be replaced approximately every 12,000 cards.