6-58

6.5 Faults - No on-screen indications

6.5.1 Chipped print (lower dots)

CAUTION

1.

If the ink stream is not centered with respect to the gutter,

dots having a small amount of deflection (lower dots of

characters) may collide against the gutter and fail to jet out

of the nozzle head, thereby causing chipped prints.

Position the ink stream at the center of the gutter.

2.

If the ink pressure rises, the ink stream flow rate increases

to decrease the amount of deflection, causing dots having a

small amount of deflection to collide against the gutter and

producing chipped prints. Ensure that the ink pressure

setting is within the specified limits.

Direction of

deflection

Missing dots

Gutter

Ink/foreign

matter

Print

drop

Chipped print

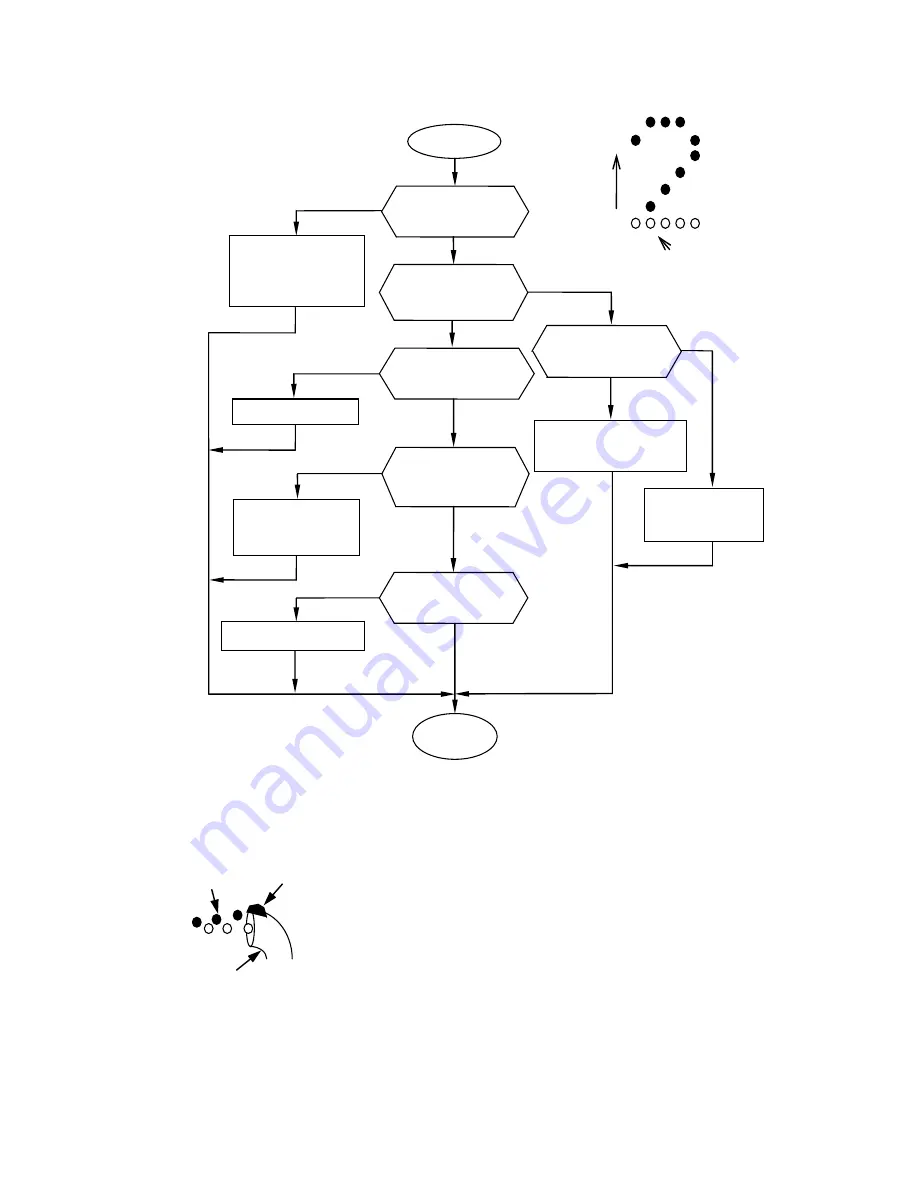

Replace the ink.

Adjust the ink stream

position so that the ink

stream is centered with

respect to the gutter.

No

Is the ink stream

positioned at the

center of the gutter?

Yes

Is the ink pressure

higher that the

specified limit?

No

Yes

Has the operating

time exceeded the ink

shelf life?

No

Yes

Resume the

operation.

Pour the makeup

over the gutter edge

section to clean it.

Is there ink or dirt

buildup on top of the

gutter edge section?

Yes

No

Adjust the charge voltage.

Yes

Is the charge

voltage properly

adjusted?

No

Adjust the ink

pressure until it is

within the limits.

Can the ink pressure be

adjusted?

No

Yes

Provide pressure relief,

then replace the

pressure-reducing valve.

Summary of Contents for IJ UX

Page 1: ...Service Manual HITACHI Printer Model UX Revision July 1 2015 Version ...

Page 2: ... Revision of UX service manual Revision Chapter Revised Page Frist Edition ...

Page 15: ...1 9 2 External views Rear side 1 2 2 Main body internal Appearance with inner cover T removed ...

Page 16: ...1 10 1 2 3 Print head UX E UX D B Air exhaust port ...

Page 107: ...3 27 Circuit diagram of EZJ127A ...

Page 108: ...3 28 Circuit diagram of EZJ127B ...

Page 122: ...3 42 Circuit diagram of EZJ129 ...

Page 131: ...3 51 3 3 20 Electrical Connection Diagram ...

Page 132: ...3 52 ...

Page 188: ...4 55 5 Reset the time of the R air filter to 0 on the Parts usage time management screen ...

Page 301: ...7 Attached Drawing 7 1 Circulation System Diagram Circulation System Diagram UX B D 7 1 ...

Page 302: ...Circulation System Diagram UX E 7 2 ...

Page 305: ...7 5 7 2 2 Electrical Connection Diagram UX B Basic model Electrical Connection Diagram UX B ...

Page 308: ... Nozzle diameter 65μm 7 8 7 4 Dimensions around charge electrode and deflection electrode ...