Appendix 8 Stored Pitch Error Compensation Function

347

Appendi

x

set -3 as the compensation amount in the range -40000

~

-50000;

set +7 as the compensation amount in the range -30000

~

-40000;

set 0 as the compensation amount in the range -20000

~

30000;

set -2 as the compensation amount in the range -10000

~

20000

When the X axis moves from -40000 to the reference point, the total pitch error compensation amount

is

(

+3

)

+

(

-7

)

+

(

0

)

+

(

2

)

=

(

-2

)

(3)

Pitch error compensation of rotary axis

When the pitch error compensation is performed for the 4th axis (when it is rotary axis), the

parameters are set as follows:

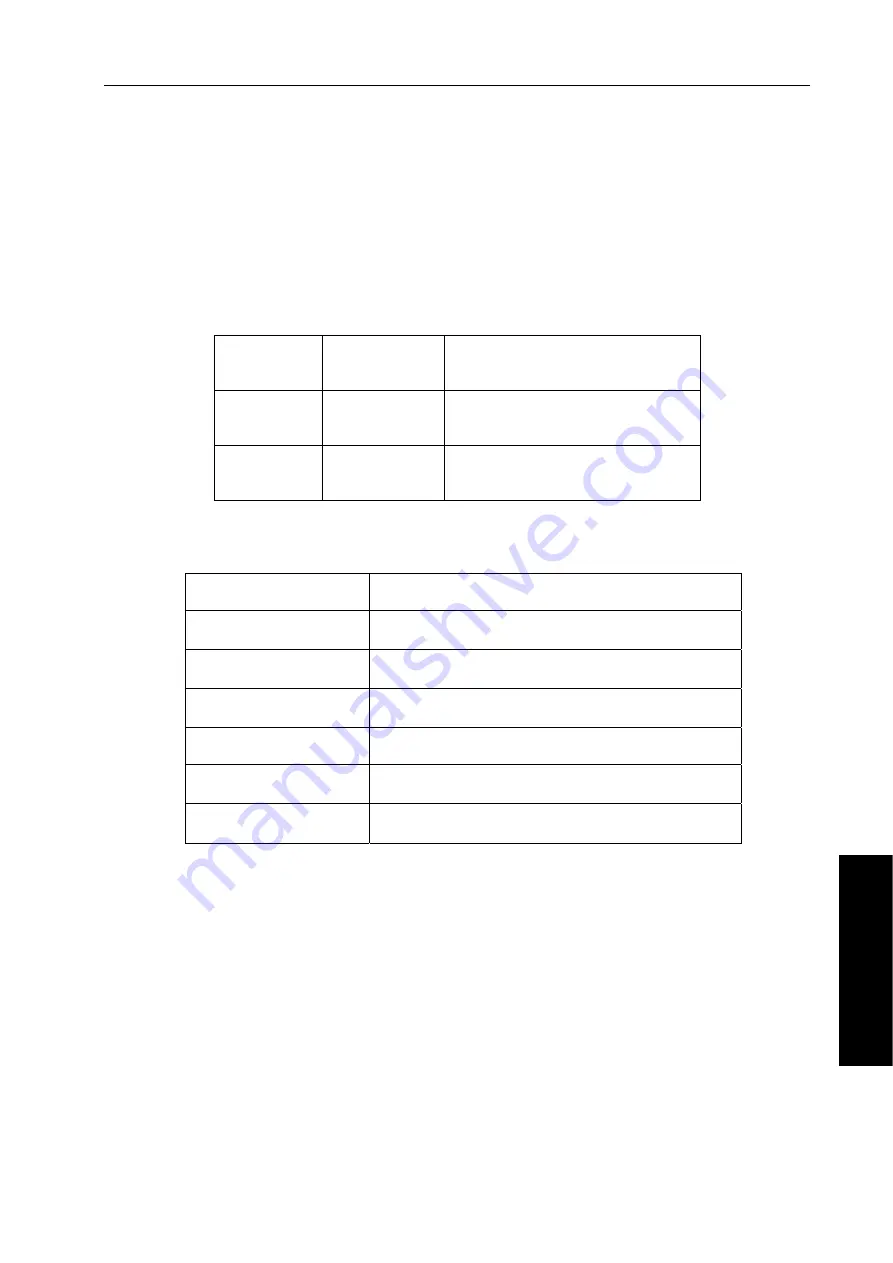

Parameter

No.

Contents

Parameter Setting Value

42 Compensation

origin point

0

166 Compensation

interval

6000

The compensation error origin point is 0; compensation interval is 6000. Divide the circle into 60

equal sections, so the compensation can be made every 6 deg. The compensation value is set at

the following 61 compensation points:

Parameter No.

Parameter Setting Value

4000

Compensation amount set between -6°

~

0°

4001

Compensation amount set between 0°

~

6°

4002

Compensation amount set between 6°

~

12°

┆

┆

4059

Compensation amount set between 348°

~

354°

4060

Compensation amount set between 354°

~

360°

The value set by parameter No. 4000 and parameter No. 4060 can be the same. The pitch error

compensation of rotary axis is performed at the speed 110000deg/min(31.2r/min) or below.

The sign “+” or ”-” of pitch error compensation value depends on the moving direction, which

means when the compensation value is “+”, the movement amount adds one compensation value;

when the compensation value is ”-”, the movement amount minus one compensation value. That is,

when the mechanical movement amount contains a error (“+” or ”-”) comparing with the movement

command, a compensation value (“+” or ”-”) is set.

When the error is “+” (excessive movement), the compensation value is ”-”.

When the error is “-” (insufficient movement), the compensation value is ”+”.

(Example)

Summary of Contents for GSK983Ma

Page 124: ......

Page 143: ......

Page 185: ......

Page 209: ...Chapter Four Operation 197 Part 2 Operation ...

Page 239: ...Chapter Four Operation 227 Part 2 Operation ...

Page 242: ......

Page 279: ......

Page 296: ...GSK983Ma Milling Machine Center CNC System User Manual 284 Part 2 Operation ...

Page 371: ...Appendix 11 USB Interface Parameter Transfer Operation ...