Chapter 2. Instrument Setup

USM Go Operator’s Manual

51

2.5 Adjusting the A-Scan

To configure the USM Go A-Scan, follow the instructions in this section.

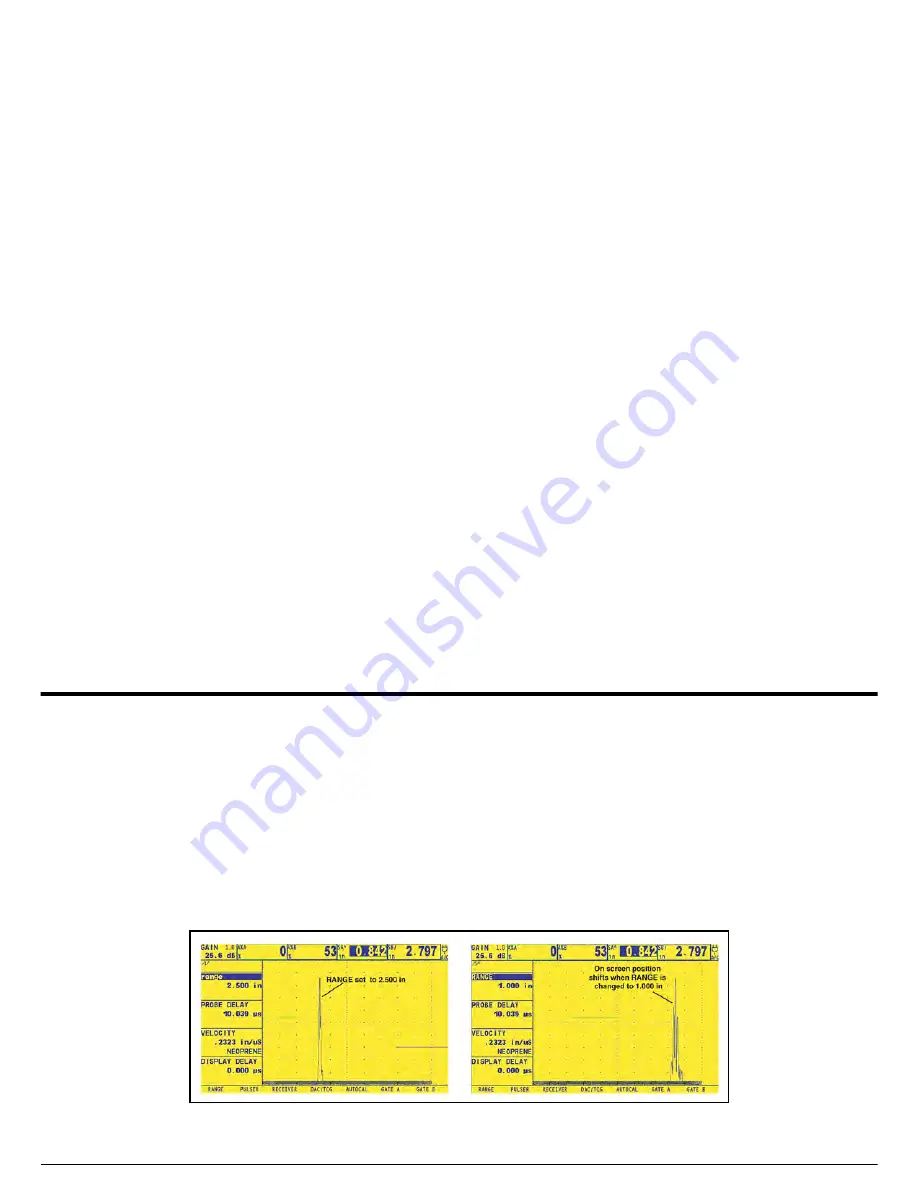

2.5.1 Setting the A-Scan Range

Calibration of the USM Go requires the use of two calibrated standards. These standards must be of different thicknesses, and they must be

made of the same material as the test piece. Prior to calibrating the instrument/probe combination, the the A-Scan display range, which is the

material thickness value represented by the full horizontal width of the screen, is normally set to a value equal to or slightly larger than the

thicker calibrated standard (see

Figure 13

below).

Figure 13: Effects of the A-Scan Range Adjustment

Summary of Contents for Ultrasonic USM Go

Page 2: ......

Page 4: ... no content intended for this page proceed to next page ...

Page 18: ...Preface xvi USM Go Operator s Manual no content intended for this page proceed to next page ...

Page 162: ...144 USM Go Operator s Manual no content intended for this page proceed to next page ...

Page 178: ...Appendix C EN 12668 Specifications 160 USM Go Operator s Manual ...

Page 189: ......