GE M

EDICAL

S

YSTEMS

D

IRECTION

FC091194, R

EVISION

02

V

IVID

7 / V

IVID

7 PRO S

ERVICE

M

ANUAL

4 - 14

Section 4-3 - Functional Checks

Section 4-3

Functional Checks

4-3-1

Preparation

Turn on power to Vivid 7 / Vivid 7 PRO, see

4-2-1 - Power ON/ Boot Up

on page

4-2.

4-3-2

Basic Controls

4-3-2-1

Introduction

Most of the mode dependant controls can be found as Mode Dependant Keys (Assignable Rotary

Knobs and Assignable Push Buttons) and Trackball. The functions available on the Mode Dependant

Keys and Trackball vary according to the scan mode and position that is currently active.

4-3-2-2

Assignable Rotary Knobs

Vivid 7 / Vivid 7 PRO has four assignable rotary knobs. The assigned functions are indicated above the

rotary on the LCD display.

4-3-2-3

Assignable Push Buttons

Vivid 7 / Vivid 7 PRO has five Assignable Push Buttons. The assigned functions are indicated above the

button on the LCD display.

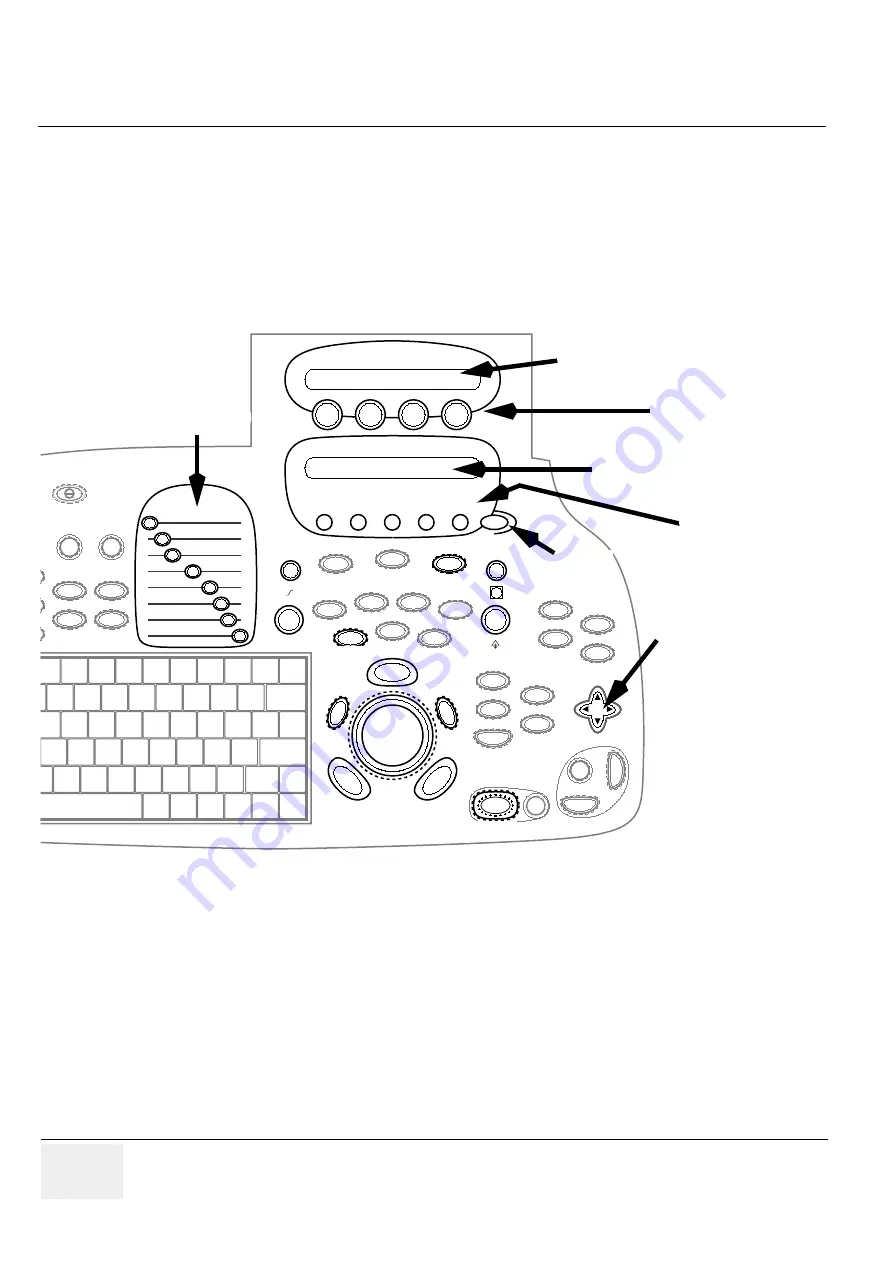

Figure 4-9 2D Mode, 2D Freeze and Cine Replay Controls

Assignable Rotaries

TGC controls

Display for Assignable Rotaries

Assignable

Push Buttons

4-way Rocker

(used to control the on-

screen Soft Menu)

More key

Display for

Assignable Push Buttons

Gain

2D

Freeze