Chapter 2 - Principle of Operation, Page 2-4__________________________________________________

Grease Extraction/Smoke Removal – Cont.

UV Lamps

Once the baffles and Particulate Separator have collected the grease particles larger than 1 micron, the

UV lamps will break down the remaining grease particles by direct exposure to 254nm light and by the

Ozone, Hydroxyl Radicals and Anionic oxygen created by the 187nm UV light and oxidizing the grease into

a light gray dust. The Ozone will carry down the ductwork and continue to break down the grease

particulate and odor molecules keeping the ductwork much cleaner. The byproducts of this process are

CO2, H20 and the base minerals from the grease and particulate matter coming off of the cooking

surface. The light gray dust that collects on the lamps is washed away each day during the Wash Cycle.

UV Systems are used to remove a high percentage of grease that the baffles and Particulate Separators

cannot remove, offering many benefits to the owner/operator.

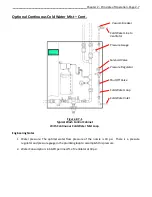

The UV Lamps are mounted in an UVi Module which slide into a track downstream of the Particulate

Separator (refer to Figure 2-3-1). The Ballasts are mounted in the front portion of the module and other

electronics are mounted in the electrical raceway (Refer to Figure 6-7-1 and 6-15-1).

The Command

Center monitors and displays text indicating the status of the UV System, and Safety Interlocks. Refer to

your Command Center Tech Manual for specific text displayed.

For proper UV operation, the Ventilators must be maintained in good working order. The UV system

must be inspected periodically and the lamps replaced as necessary. The Ventilator, ductwork and

exhaust fan must be inspected in accordance with NFPA-96 or local guidelines, though frequency of duct

cleanings should be significantly reduced. Refer to Chapter 4

for maintenance details.

UV Safety

Caution: Exposure to UV light is harmful to skin and eyes.

The CG3-UVi-SPC Series Ventilator is equipped with panels and Safety Interlocks to protect operators

from direct exposure to UV light. All safety precautions called for in this manual must be followed to

avoid the potential for harm to operators or service personnel. Refer to Page 4-9 for complete

description of safety precautions.

Smoke Removal

The Ventilator removes smoke particles by the use of Electrostatic Precipitator Cells (ESP Cells) located

after the UV section (Refer to Figure 2-3-1).

The principle of operation of electrostatic precipitation is

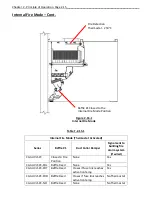

actually quite basic. The Electrostatic Cell is made up of a series of aluminum plates spaced approximately

1/4” (6.35mm) apart (Refer to Figure 2-5-1).

Every other plate is energized with 5000 volts of D.C. power

and the alternating plates are grounded. At the entry point of the Cell is a series of thin wires spaced

approximately 4” (101.60mm) apart (Refer to Figure 2-5-1). These wires, referred to as ionizing wires, are

energized with 10,000 volts D.C. and as the smoke particles enter the Cell and pass over the wires they

receive a positive charge. As the charged smoke particles continue through the Cell, the positive plate repels

them and the negative or grounded plate attracts them. Thus, the smoke particles are collected on the

negative plates. The action is efficient, safe and simple.