Setup & Operation 4. Setting of End Effectors

LS20 Rev.4

41

4. Setting of End Effectors

4.1 Attaching an End Effector

Users are responsible for making their own end effector(s). Before attaching an end

effector, observe these guidelines.

CAUTION

■

If you use an end effector equipped with a gripper or chuck, connect wires and/or

pneumatic tubes properly so that the gripper does not release the work piece

when the power to the robot system is turned OFF. Improper connection of the

wires and/or pneumatic tubes may damage the robot system and/or work piece

as the work piece is released when the Emergency Stop switch is pressed.

I/O outputs are configured at the factory so that they are automatically shut off (0)

by power disconnection, the Emergency Stop switch, or the safety features of the

robot system.

Shaft

- Attach an end effector to the lower end of the shaft.

For the shaft dimensions, and the overall dimensions of the Manipulator, refer to

Setup

& Operation: 2. Specifications

.

- Do not move the upper limit mechanical stop on the lower side of the shaft.

Otherwise, when “Jump motion” is performed, the upper limit mechanical stop may hit

the Manipulator, and the robot system may not function properly.

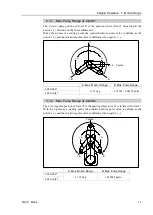

- Use a split muff coupling with an M4 bolt or larger to attach the end effector to the

shaft.

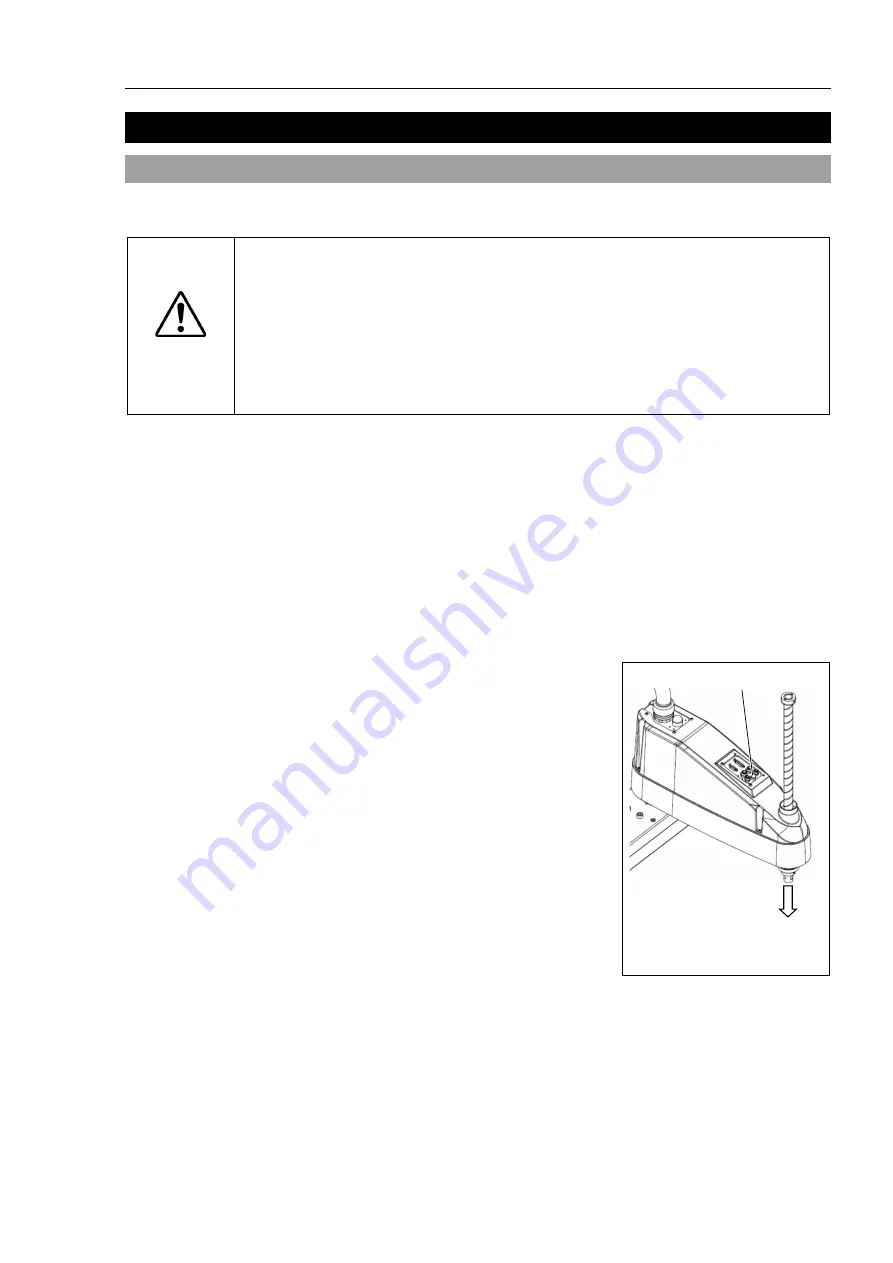

Brake release switch

- Joint #3 and #4 cannot be moved up/down and rotate

by hand because the solenoid brake is applied to the

joint while power to the robot system is turned OFF.

This prevents the shaft from hitting peripheral

equipment in the case that the shaft is lowered and

the end effector is rotated by the weight of the end

effector when the power is disconnected during

operation, or when the motor is turned OFF even

though the power is turned ON.

To move Joint #3 up/down or rotate Joint #4 while

attaching an end effector, turn ON the Controller and

move the joint up/down or rotate the joint while

pressing the brake release switch.

Brake release switch

The shaft may be lowered by

the weight of the end effector.

This button switch is a momentary-type; the brake is released only while the button

switch is being pressed.

The respective brakes for Joints #3 and #4 are released simultaneously.

- Be careful of the shaft falling and rotating while the brake release switch is pressed

because the shaft may be lowered by the weight of the end effector.

Summary of Contents for LS20

Page 1: ...Rev 4 EM179R3533F SCARA ROBOT LS20 series MANIPULATOR MANUAL ...

Page 2: ...MANIPULATOR MANUAL LS20 series Rev 4 ...

Page 8: ...vi LS20 Rev 4 ...

Page 12: ...TABLE OF CONTENTS x LS20 Rev 4 ...

Page 14: ......

Page 29: ...Setup Operation 2 Specifications LS20 Rev 4 17 LS20 804S Standard Model ...

Page 31: ...Setup Operation 2 Specifications LS20 Rev 4 19 LS20 804C Cleanroom Model ...

Page 33: ...Setup Operation 2 Specifications LS20 Rev 4 21 LS20 A04S Standard Model ...

Page 35: ...Setup Operation 2 Specifications LS20 Rev 4 23 LS20 A04C Cleanroom Model ...

Page 72: ......

Page 92: ...Maintenance 4 Cable 80 LS20 Rev 4 4 2 Wiring Diagrams 4 2 1 Signal Cable ...

Page 176: ...Maintenance 14 Maintenance Parts List 164 LS20 Rev 4 ...