Setup & Operation 1. Safety

LS20 Rev.4

11

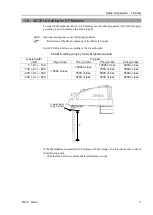

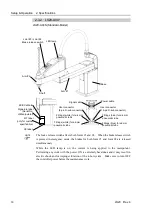

1.6 ACCELS Setting for CP Motions

To make the Manipulator move in CP motion, see the following and set ACCELS properly

according to the tip load and the Z-axis height.

Improper setting may cause following problems.

Reduction of the life and damage of the ball screw spline

Set ACCELS as follows according to the Z-axis height.

ACCELS setting value by Z-axis height and tip load

Z-axis height

(mm)

Tip load

5 kg or less

10 kg or less

15 kg or less

20 kg or less

0 > Z >= - 100

10000 or less

10000 or less

10000 or less

9000 or less

- 100 > Z >= - 200

7000 or less

5500 or less

- 200 > Z >= - 300

7500 or less

5000 or less

3500 or less

- 300 > Z >= - 420

5500 or less

3500 or less

2500 or less

Z-axis height 0

(Origin point)

Z

If the Manipulator is operated in CP motion with the wrong set values, make sure to check

the following point.

Whether the ball screw spline shaft is deformed or bent

NOTE

Summary of Contents for LS20

Page 1: ...Rev 4 EM179R3533F SCARA ROBOT LS20 series MANIPULATOR MANUAL ...

Page 2: ...MANIPULATOR MANUAL LS20 series Rev 4 ...

Page 8: ...vi LS20 Rev 4 ...

Page 12: ...TABLE OF CONTENTS x LS20 Rev 4 ...

Page 14: ......

Page 29: ...Setup Operation 2 Specifications LS20 Rev 4 17 LS20 804S Standard Model ...

Page 31: ...Setup Operation 2 Specifications LS20 Rev 4 19 LS20 804C Cleanroom Model ...

Page 33: ...Setup Operation 2 Specifications LS20 Rev 4 21 LS20 A04S Standard Model ...

Page 35: ...Setup Operation 2 Specifications LS20 Rev 4 23 LS20 A04C Cleanroom Model ...

Page 72: ......

Page 92: ...Maintenance 4 Cable 80 LS20 Rev 4 4 2 Wiring Diagrams 4 2 1 Signal Cable ...

Page 176: ...Maintenance 14 Maintenance Parts List 164 LS20 Rev 4 ...