Maintenance 10. Ball Screw Spline Unit

LS20 Rev.4

135

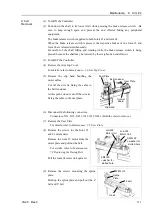

10.2 Replacing the Ball Screw Spline Unit

A brake is mounted on the motor of Joints #3 and #4 to prevent the shaft from moving

down due to the weight of the end effector while the power to the Controller is OFF or

while the motor is in OFF status (MOTOR OFF).

Move the shaft down to its lower limit before the replacement procedure following the

removal steps.

Name

Quantity

Note

Maintenance

parts

Ball Screw Spline Unit

1

Each manipulator model

(Refer to

Maintenance:

14. Maintenance parts

)

For Ball Screw Spline Unit (AFB grease)

Proper

quantity 6012557

Tools

Hexagonal wrench

width across flats: 3 mm

1

For M4 screw

width across flats: 4 mm

1

For M5 screw

Torque wrench

1

Nippers

1

For cutting wire tie

Cross-point screwdriver (#2)

1

Wiping cloth

1

For wiping grease (Spline shaft)

Material

Wire tie

-

Grease

For Ball Screw Spline Unit (AFB grease)

Proper

quantity -

Ball Screw

Spline Unit

Removal

(1) Turn ON the Controller.

(2) Push down the shaft to its lower limit while pressing the brake release switch. Be

sure to keep enough space and prevent the end effector hitting any peripheral

equipment.

The brake release switch is applied to both Joints #3 and Joint #4.

When the brake release switch is pressed, the respective brakes of the Joint #3 and

Joint #4 are released simultaneously.

Be careful of the shaft falling and rotating while the brake release switch is being

pressed because the shaft may be lowered by the weight of an end effector.

(3) Turn OFF the Controller.

(4) Detach the wires/tubes from the end effector, and remove the end effector.

(5) This step is only for Cleanroom-model.

Remove the bellows. For details, refer to

Maintenance: 9. Bellows

.

(6) Remove the Arm Top Cover and Arm Bottom Cover.

For details, refer to

Maintenance: 3. Covers

.

(7) Remove the following.

Joint #3 motor unit, Joint #4 motor unit

For details, refer to

Maintenance: 7.1 Replacing Joint #3 Motor s

.

Maintenance:8.1 Replacing Joint #4 Motor s

.

NOTE

Summary of Contents for LS20

Page 1: ...Rev 4 EM179R3533F SCARA ROBOT LS20 series MANIPULATOR MANUAL ...

Page 2: ...MANIPULATOR MANUAL LS20 series Rev 4 ...

Page 8: ...vi LS20 Rev 4 ...

Page 12: ...TABLE OF CONTENTS x LS20 Rev 4 ...

Page 14: ......

Page 29: ...Setup Operation 2 Specifications LS20 Rev 4 17 LS20 804S Standard Model ...

Page 31: ...Setup Operation 2 Specifications LS20 Rev 4 19 LS20 804C Cleanroom Model ...

Page 33: ...Setup Operation 2 Specifications LS20 Rev 4 21 LS20 A04S Standard Model ...

Page 35: ...Setup Operation 2 Specifications LS20 Rev 4 23 LS20 A04C Cleanroom Model ...

Page 72: ......

Page 92: ...Maintenance 4 Cable 80 LS20 Rev 4 4 2 Wiring Diagrams 4 2 1 Signal Cable ...

Page 176: ...Maintenance 14 Maintenance Parts List 164 LS20 Rev 4 ...