Maintenance 7. Arm #3

LS20 Rev.4

109

Z belt

Installation

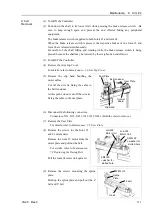

(1) Pass a new Z belt through the shaft.

Z Belt

Spline Plate

3-M4×15

Shaft

(2) Lower the spline plate with the Z belt

placed around the spline plate pulley.

Secure the spline plate with 3 screws.

Fix the screws temporarily so that the

spline plate can be moved by hand.

Fix the spline plate with the screws

while pushing the front side of the Arm

#2 and the right side face.

Faces to push the

spline plate

(3) Pass the Z belt between the motor plate

of the Joint #3 motor unit and the brake

plate.

Motor Plate

Z belt

Brake Plate

(4) Mount the Joint #3 motor to the motor

plate while aligning the hub to the

brake disc.

Install the motor so that the pulley will

be inside of the Z belt.

Joint #3

Motor

Motor Plate

4-M5×15

Z belt

(5) Temporarily fix the Joint #3 motor unit

to the Arm #2.

Make sure that the teeth of the timing

belt are engaged with those of the

pulley.

Joint #3

Motor Unit

3-M5×20 + washer for

slotted hole

At this point, make sure that the Joint #3 motor unit can be moved by hand, and it

will not tilt when pulled. If the unit is tilted, the belt will not have the proper

tension.

NOTE

Summary of Contents for LS20

Page 1: ...Rev 4 EM179R3533F SCARA ROBOT LS20 series MANIPULATOR MANUAL ...

Page 2: ...MANIPULATOR MANUAL LS20 series Rev 4 ...

Page 8: ...vi LS20 Rev 4 ...

Page 12: ...TABLE OF CONTENTS x LS20 Rev 4 ...

Page 14: ......

Page 29: ...Setup Operation 2 Specifications LS20 Rev 4 17 LS20 804S Standard Model ...

Page 31: ...Setup Operation 2 Specifications LS20 Rev 4 19 LS20 804C Cleanroom Model ...

Page 33: ...Setup Operation 2 Specifications LS20 Rev 4 21 LS20 A04S Standard Model ...

Page 35: ...Setup Operation 2 Specifications LS20 Rev 4 23 LS20 A04C Cleanroom Model ...

Page 72: ......

Page 92: ...Maintenance 4 Cable 80 LS20 Rev 4 4 2 Wiring Diagrams 4 2 1 Signal Cable ...

Page 176: ...Maintenance 14 Maintenance Parts List 164 LS20 Rev 4 ...