Maintenance 7. Arm #3

LS20 Rev.4

111

7.3 Replacing the Brake

Name

Quantity

Note

Maintenance

parts

Electromagnetic brake

1

1499588

Tools

Hexagonal wrench

width across flats: 1.5 mm

1

For M3 set screw

width across flats: 3 mm

1

For M4 screw

width across flats: 4 mm

1

For M5 screw

Torque wrench

1

Nippers

1

For cutting wire tie

Ultrasonic tension meter

1

Refer: Unitta U-508

The brakes are mounted on the Joints #3 and #4 to prevent the shaft from moving down

due to the weight of the end effector while the power to the Controller is OFF or while the

motor is in OFF status (MOTOR OFF).

Move the shaft down to its lower limit before the replacement procedure following the

removal steps.

Joint #3 brake

Removal

(1) Turn ON the Controller.

(2) Push down the shaft to its lower limit while pressing the brake release switch. Be

sure to keep enough space and prevent the end effector hitting any peripheral

equipment.

The brake release switch is applied to both Joints #3 and Joint #4. When the

brake release switch is pressed, the respective brakes of the Joint #3 and Joint #4

are released simultaneously. Be careful of the shaft falling and rotating while

the brake release switch is being pressed because the shaft may be lowered by

the weight of an end effector.

(3) Turn OFF the Controller.

(4) Remove the Arm Top Cover.

For details, refer to

Maintenance: 3.1 Arm Top Cover

.

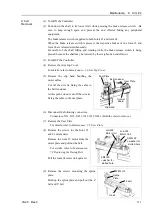

(5) Remove the clip band binding the motor

cables.

Remove the wire tie on the cables fixed to

the belt tensioner.

At this point, do not cut off a wire tie that

binds the cables to the Duct Plate.

Control

Board

Clip Band

User Plate

Belt Tensioner

Duct Plate

(6) Disconnect the following connector.

Connector: X32

NOTE

Summary of Contents for LS20

Page 1: ...Rev 4 EM179R3533F SCARA ROBOT LS20 series MANIPULATOR MANUAL ...

Page 2: ...MANIPULATOR MANUAL LS20 series Rev 4 ...

Page 8: ...vi LS20 Rev 4 ...

Page 12: ...TABLE OF CONTENTS x LS20 Rev 4 ...

Page 14: ......

Page 29: ...Setup Operation 2 Specifications LS20 Rev 4 17 LS20 804S Standard Model ...

Page 31: ...Setup Operation 2 Specifications LS20 Rev 4 19 LS20 804C Cleanroom Model ...

Page 33: ...Setup Operation 2 Specifications LS20 Rev 4 21 LS20 A04S Standard Model ...

Page 35: ...Setup Operation 2 Specifications LS20 Rev 4 23 LS20 A04C Cleanroom Model ...

Page 72: ......

Page 92: ...Maintenance 4 Cable 80 LS20 Rev 4 4 2 Wiring Diagrams 4 2 1 Signal Cable ...

Page 176: ...Maintenance 14 Maintenance Parts List 164 LS20 Rev 4 ...