Maintenance 6. Arm #2

LS20 Rev.4

95

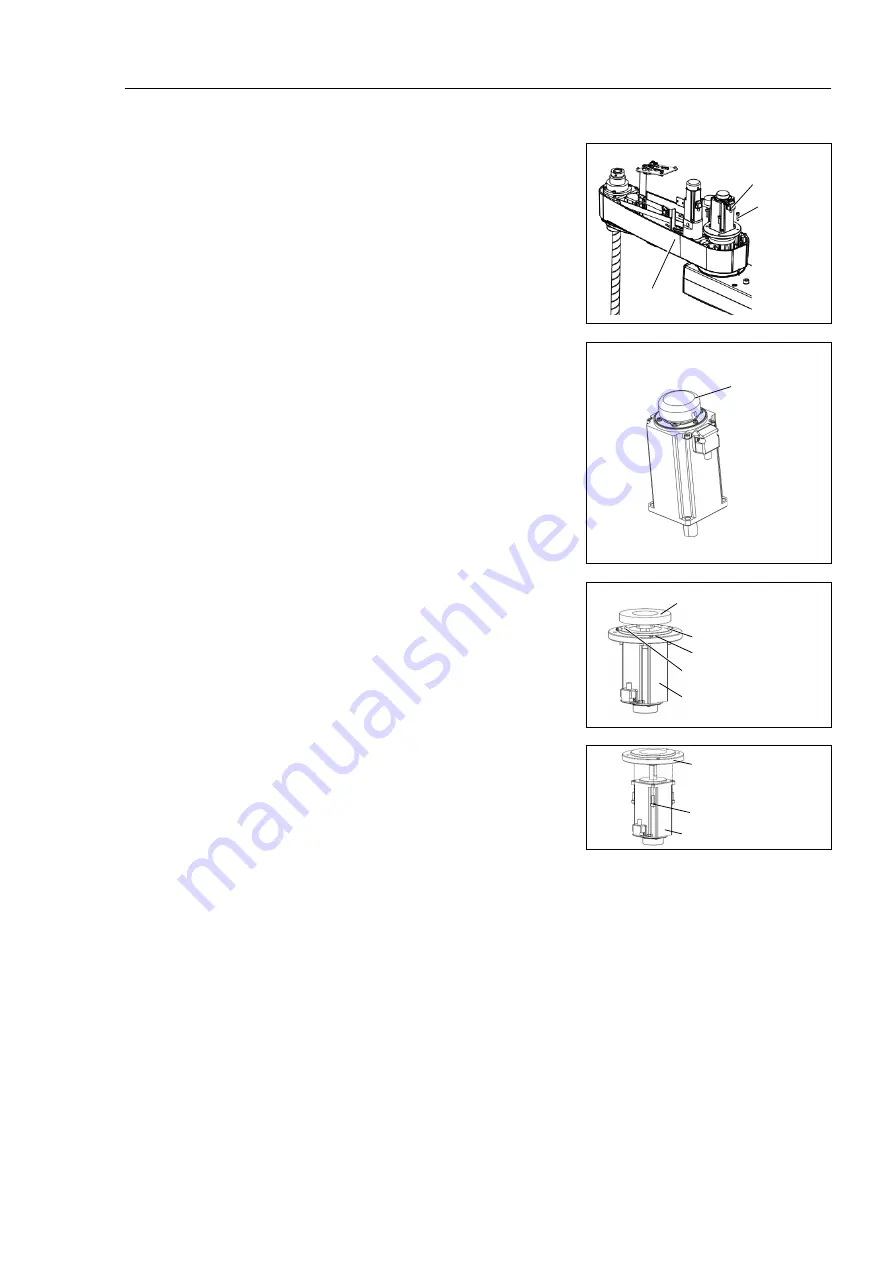

(7) Disconnect the connectors X221 and X21. (Hold the claw to remove.)

(8) Remove the screws mounting the motor unit

and then remove the Joint #2 motor unit

from the Arm #2.

To pull out the motor smoothly, move the

Arm #2 slowly by hand while pulling the

motor.

4-M5

×

20

Joint #2

Motor Unit

Arm #2

When replacing the motor of the Joint #2,

remove the cap from the old motor and

install it to the new one.

If the Manipulator is operated while the cap

is not installed, the motor may be damaged

due to entering of the foreign materials into

the rotating part of the motor sensor and

interference of the rotating part and the

cables.

cap

(9) Remove the waveform generator from the

Joint #2 motor.

There is a brass bushing in one of the set

screw holes. Be sure to keep the bushing.

The O ring will be used again. Be careful

not to lose it.

2-M5

×

8 Set Screw

M5 Brass Bushing

Joint #2 Motor

Waveform Generator

O-Ring

(10) Remove the motor flange from the Joint #2

motor.

Motor Flange

Joint #2 Motor

2-M5

×

15

NOTE

Summary of Contents for LS20

Page 1: ...Rev 4 EM179R3533F SCARA ROBOT LS20 series MANIPULATOR MANUAL ...

Page 2: ...MANIPULATOR MANUAL LS20 series Rev 4 ...

Page 8: ...vi LS20 Rev 4 ...

Page 12: ...TABLE OF CONTENTS x LS20 Rev 4 ...

Page 14: ......

Page 29: ...Setup Operation 2 Specifications LS20 Rev 4 17 LS20 804S Standard Model ...

Page 31: ...Setup Operation 2 Specifications LS20 Rev 4 19 LS20 804C Cleanroom Model ...

Page 33: ...Setup Operation 2 Specifications LS20 Rev 4 21 LS20 A04S Standard Model ...

Page 35: ...Setup Operation 2 Specifications LS20 Rev 4 23 LS20 A04C Cleanroom Model ...

Page 72: ......

Page 92: ...Maintenance 4 Cable 80 LS20 Rev 4 4 2 Wiring Diagrams 4 2 1 Signal Cable ...

Page 176: ...Maintenance 14 Maintenance Parts List 164 LS20 Rev 4 ...