Maintenance 8. Arm #4

126

LS20 Rev.4

8.4 Replacing the Reduction Gear Unit

Name

Quantity

Note

Maintenance

parts

R

eduction

G

ear

U

nit

1

1493783

Tools

Hexagonal wrench

width across flats: 3 mm

1

For M4 screw

width across flats: 4 mm

1

For M5 screw

Spanner

width across flats: 7 mm

2

For M4 hexagon head bolt

and M4 hexagon nut

Cross-point screwdriver (#2)

1

For M4 screw

Torque wrench

1

Ultrasonic tension meter

1

Refer: Unitta U-508

Material

Wire tie

-

For binding cables

The brakes are mounted on the Joints #3 and #4 to prevent the shaft from moving down

due to the weight of the end effector while the power to the Controller is OFF or while the

motor is in OFF status (MOTOR OFF).

Move the shaft down to its lower limit before the replacement procedure following the

removal steps.

Joint #4

Reduction Gear

Unit

Removal

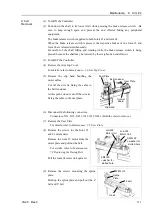

(1) Remove the Joint #4 motor unit from the Arm #2.

For details, refer to the Installation steps in

Maintenance: 8.2 Replacing the Timing Belt

.

2-M4

×

12

Joint #4 Motor

Joint #4

Reduction Gear Unit

Screw hole for fixing

the motor shaft

(2) Remove the Joint #4 motor from the reduction

gear unit.

Remove the screws securing the Joint #4 motor

to the reduction gear unit.

Remove the cover of the hole for fixing the motor shaft on the side of the reduction

gear, and loosen the screw. If the screw position does not match, turn the motor

slightly and move until the screw fixing the motor shaft can be seen.

After loosening the screw, mount the cover to the hole. Pull the motor upward to

remove.

(3) Remove the U pulley.

Joint #4

Reduction Gear Unit

6-M4

×

15

Pulley

(4) Remove the plate.

Joint #4

Reduction gear Unit

Plate

4-M5

×

18

NOTE

Summary of Contents for LS20

Page 1: ...Rev 4 EM179R3533F SCARA ROBOT LS20 series MANIPULATOR MANUAL ...

Page 2: ...MANIPULATOR MANUAL LS20 series Rev 4 ...

Page 8: ...vi LS20 Rev 4 ...

Page 12: ...TABLE OF CONTENTS x LS20 Rev 4 ...

Page 14: ......

Page 29: ...Setup Operation 2 Specifications LS20 Rev 4 17 LS20 804S Standard Model ...

Page 31: ...Setup Operation 2 Specifications LS20 Rev 4 19 LS20 804C Cleanroom Model ...

Page 33: ...Setup Operation 2 Specifications LS20 Rev 4 21 LS20 A04S Standard Model ...

Page 35: ...Setup Operation 2 Specifications LS20 Rev 4 23 LS20 A04C Cleanroom Model ...

Page 72: ......

Page 92: ...Maintenance 4 Cable 80 LS20 Rev 4 4 2 Wiring Diagrams 4 2 1 Signal Cable ...

Page 176: ...Maintenance 14 Maintenance Parts List 164 LS20 Rev 4 ...