64

Control panel

rEF

MENU

FWD

LOC

49

.

1

Hz

SET

FWD

50

.

0

Hz

SET

FWD

Step

Action

Display

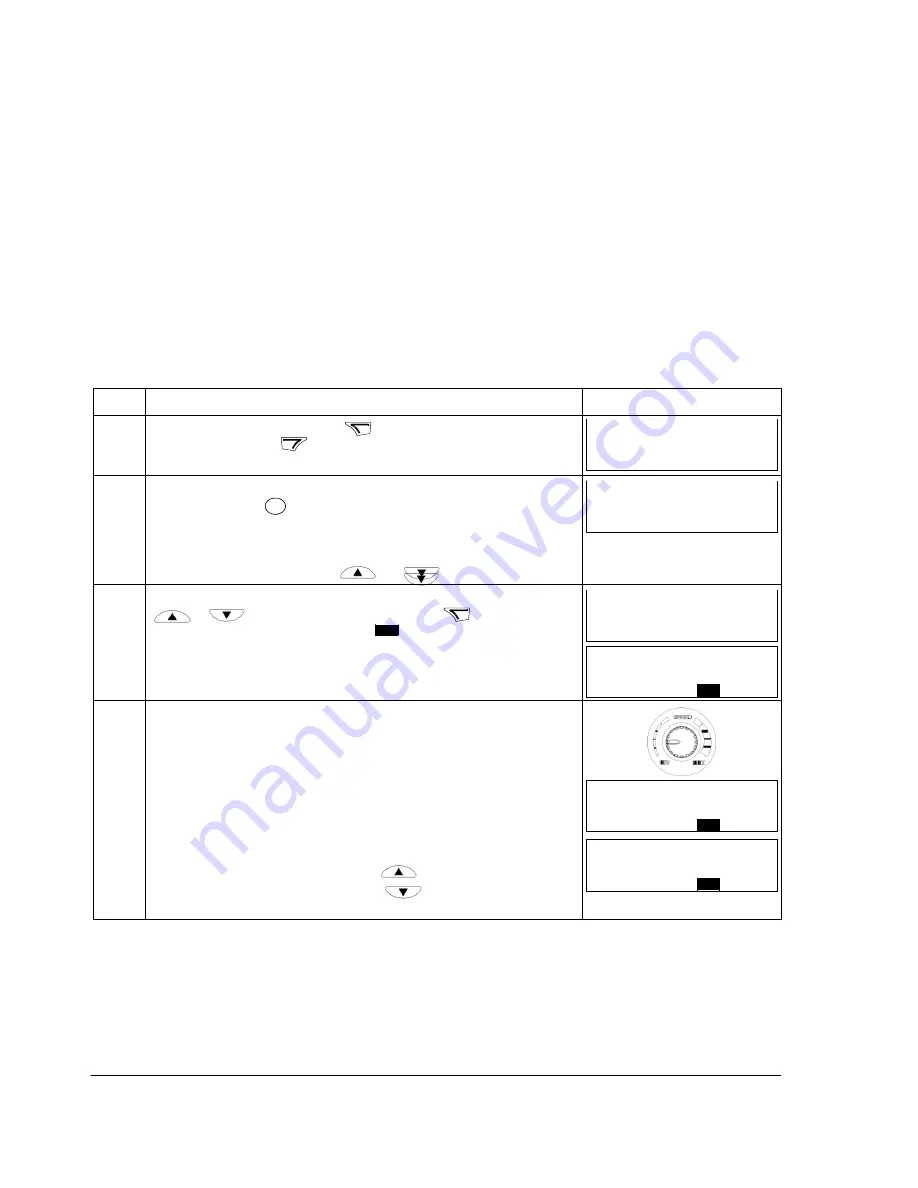

1.

Go to the Main menu by pressing

if you are in the Output mode,

otherwise by pressing

repeatedly until you see MENU at the bottom.

REM

PAr S

MENU

FWD

2.

If the drive is in remote control (REM shown on the left), switch to local

control by pressing

LOC

. The display briefly sh

ows “LoC” before switching

REM

to local control.

Note

: With group

11 REFERENCE SELECT

, you can allow changing of the

remote (external) reference in remote control (REM) for example, using the

integrated potentiometer or keys and

.

LOC

PAr S

MENU

FWD

3.

or

until you see “rEF” and then press

. Now the display

shows the current reference value with

SET

under the value.

LOC

4.

If parameter

1109

LOC REF SOURCE = 0 (POT, default):

• To increase the reference value, rotate the integrated potentiometer

clockwise.

• To decrease the reference value, rotate the integrated potentiometer

counterclockwise.

The new value (potentiometer setting) is shown on the display.

• To increase the reference value, press

.

• To decrease the reference value, press

.

The new value is shown on the display.

LOC

Reference mode

In the Reference mode, you can:

• view and set the frequency reference

• start, stop, change direction and switch between local and remote control.

How to view and set the frequency reference

You can set the local frequency reference with the integrated potentiometer in any

mode when the drive is in local control if parameter

1109

LOC REF SOURCE has

the default value 0 (POT). If parameter

1109

LOC REF SOURCE has been changed

to 1 (KEYPAD), you have to set the local frequency reference in the Reference

mode.

You can view the current local reference in the Reference mode only.

If the panel is not in the Reference mo

de (“rEF” not visible), press key

50

.

0

Hz

LOC

SET

FWD

If parameter

1109

LOC REF SOURCE = 1 (KEYPAD):

Summary of Contents for ACS150 series

Page 4: ......

Page 5: ......

Page 15: ...14 Safety ...

Page 19: ...18 Introduction to the manual ...

Page 39: ...38 Planning the electrical installation ...

Page 51: ...50 Installation checklist ...

Page 57: ...56 Start up and control with I O ...

Page 69: ...68 Control panel ...

Page 79: ...78 Application macros ...

Page 160: ...L Q M 0 I II D I II I I ro I m D en m D D Q Q f 3AFE68633931 A 0 Frame size R2 IP20 INEMA 1 ...

Page 161: ...ji 4 I 5 I 6 4 J ...

Page 162: ......

Page 163: ...160 Dimension drawings ...

Page 169: ...166 Appendix Process PID control ...

Page 171: ...168 ...