3-7

7.1

95-8533

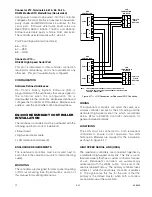

Shield Grounding

Two shield ground terminals are provided inside the

junction box of each device, and also at the System

Controller. Connect shield ends to the terminals

provided (not to each other) inside the junction box.

CAUTION!

Insulate the shields to prevent shorting to the

device housing or to any other conductor. Refer

to Appendix C for eMC Directive requirements.

Junction Box Grounding

All junction boxes must be electrically connected to

earth ground.

Response Time vs. System Size

When designing a system, it is important to realize

that by increasing the number of nodes (devices) on

the communication loop, the amount of time required

for a status change message from a detection device

to reach the System Controller also increases.

The System Controller requires a specific length of

time to process each bit of information that is

transferred along the communication loop. As the

number of nodes increases, so does the amount of

data being processed as well as the time required for

processing by the Controller.

If the fastest possible communication response time is

an important criteria for a large system, it is

recommended that the number of nodes on an

individual loop be kept as small as possible. Consider

using multiple controllers with fewer nodes per loop.

Moisture Damage Protection

Moisture can adversely affect the performance of

electronic devices. It is important to take proper

precautions during system installation to ensure that

moisture will not come in contact with electrical

connections or components.

In applications where the network wiring is installed in

conduit, the use of watertight conduit seals, drains,

breathers, or equivalent is recommended to prevent

damage caused by condensation within the conduit.

Electrostatic Discharge

An electrostatic charge can build up on the skin and

discharge when an object is touched. ALWAYS use

caution when handling devices, taking care not to

touch the terminals or electronic components.

CAUTION!

ALWAYS discharge static charges from hands

before handling electronic devices or touching

device terminals. Many devices contain

semiconductors that are susceptible to damage

by electrostatic discharge.

NOTe

For more information on proper handling, refer to

Det-Tronics Service Memo form 75-1005.

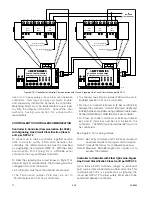

GROUND FAULT MONITOR (GFM)

INSTALLATION

Mounting

The GFM is a DIN rail mountable device designed to be

mounted in the same enclosure as the EQP controller.

Wiring

1. Connect power wiring from the EQP controller power

terminals 1 and 2 to the GFM terminals 1 and 2.

2. Connect power wiring from the GFM terminals 3 and

4 to the EQP controller power terminals 3 and 4.

3. Connect earth ground to terminal 5 or 10.

4. Connect the relay contacts as required.

Refer to Figure 3-1 for terminal block identification.

6

7

8

9

10

COMMON

NO

NC

N/C

RELAY

SPARE

1

2

3

4

5

+

+

–

–

EARTH

GROUND

+

+

–

–

EARTH

GROUND

24 VDC

INPUT VOLTAGE

NOTE: RELAY CONTACTS ARE SHOWN IN THE REST STATE,

NO POWER APPLIED. RELAY IS ENERGIZED WITH

POWER APPLIED AND NO GROUND FAULT

(TERMINALS 6 & 7 CLOSE, TERMINALS 6 & 8 OPEN).

Figure 3-1—Terminal Configuration for Ground Fault Monitor

Содержание DET-TRONICS 95-8533

Страница 1: ...Instructions 95 8533 Eagle Quantum Premier Fire and Gas Detection Releasing System 7 1 9 09 95 8533 ...

Страница 128: ...7 1 95 8533 A 4 Figure A 1 System Drawing 007545 001 ...

Страница 129: ...95 8533 A 5 7 1 Figure A 2 System Drawing 007545 001 ...

Страница 131: ...95 8533 7 1 B 2 Figure B 1 Drawing 007546 001 ...

Страница 132: ...95 8533 7 1 B 3 Figure B 2 Drawing 007546 001 ...

Страница 134: ...95 8533 7 1 C 2 Figure C 1 Drawing 007547 001 ...

Страница 141: ...95 8533 7 1 D 7 Figure D1 System Drawing 007545 001 ...

Страница 143: ...APPENDIX E E 1 95 8533 7 1 ...