7.1

3-22

95-8533

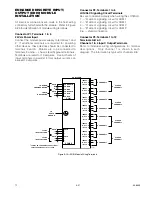

CONFIGURATION

S3 Configuration

The S3 configuration software is used to configure the

redundant controllers. A check box on the controller

configuration screen must be enabled and

downloaded to the controllers.

IMPORTANT

If the controllers have not been configured for

redundancy via the S3 configuration software,

redundancy will not function.

Controller Addresses

The LON addresses are pre-determined and cannot

be adjusted. Address 1 and 2 have been reserved for

a redundant controller configuration.

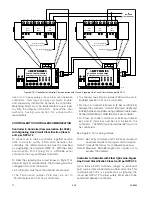

Modbus

Modbus ports on each controller share the serial

settings including baud rate and address. Controllers

in standby mode don’t respond to or issue Modbus

messages. This allows for transparent switching on a

multi-drop network. If RS-232 is used, a relay

switching mechanism can be used.

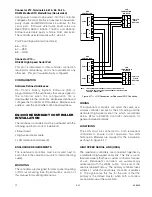

ControlNet

The ControlNet interface on each controller will have

different addresses. This allows both controllers to

reside on the same ControlNet network at the same

time. The primary controller uses the configured

address while the standby assumes an address 1

higher than the primary controller. Application logic in

the attached PLC must be used to determine which

controller has the correct output information.

Information coming from the PLC should be written to

both Premier Controllers.

EQ21XXPS SERIES POWER SUPPLY

AND POWER SUPPLY MONITOR

INSTALLATION

WARNING!

ALWAYS follow all safety notes and instructions

when installing power supply or batteries!

WARNING!

Make sure a.c. power is OFF at main a.c. breaker

before beginning power supply installation!

IMPORTANT!

Power supplies require unrestricted air flow for

proper cooling.

MOUNTING

Mount the power supply monitor in a Nationally

Recognized Test Laboratory (NRTL) labeled

enclosure. Refer to the “Specifications” section for

mounting dimensions.

WIRING

CAUTION!

The power supply should be properly connected

to an earth ground! A ground wire MUST be

connected to the power supply units’s case

ground!

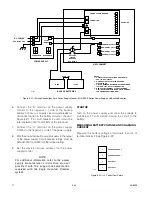

NOTe

The Power Supply Monitor uses two of the four

DIP switches to select an appropriate fault level

for the installation. See Figure 3-18. The unit will

fault when the batteries source a current level

higher than the threshold for 20 seconds. The

fault will clear when the current drops to half the

level for 20 seconds. The current level selection

is based on the minimum current draw of the

attached equipment. The selected value must be

less than the actual minimum current draw for

the system.

1. Verify that the input source is the same voltage

and frequency as that marked on the nameplate

of the power supply.

2. Verify that transformer taps are set for the correct

a.c. input. (Input tap setting is located inside the

power supply enclosure.)

3. Verify that the supply power wire size and fusing

are adequate for the current indicated on the

power supply nameplate.

NOTe

Consult the power supply manufacturer’s instruction

manual provided with the support documentation

received with the eagle Quantum System.

NOTe

Required Overload Current is usually equal to

15% of the nominal rating.

Содержание DET-TRONICS 95-8533

Страница 1: ...Instructions 95 8533 Eagle Quantum Premier Fire and Gas Detection Releasing System 7 1 9 09 95 8533 ...

Страница 128: ...7 1 95 8533 A 4 Figure A 1 System Drawing 007545 001 ...

Страница 129: ...95 8533 A 5 7 1 Figure A 2 System Drawing 007545 001 ...

Страница 131: ...95 8533 7 1 B 2 Figure B 1 Drawing 007546 001 ...

Страница 132: ...95 8533 7 1 B 3 Figure B 2 Drawing 007546 001 ...

Страница 134: ...95 8533 7 1 C 2 Figure C 1 Drawing 007547 001 ...

Страница 141: ...95 8533 7 1 D 7 Figure D1 System Drawing 007545 001 ...

Страница 143: ...APPENDIX E E 1 95 8533 7 1 ...