1.15.3

Sp in d l e D r ive System

The spindle drive system consists of a spindle assembly driven through a drive belt by a brushless

D.C. motor/tachometer.

The servo electronics required for speed control are located on the printed circuit board.

The control circuitry contains an interface control line. When the drive motor control interface line is

false (high), the drive motor is allowed to come up to speed.

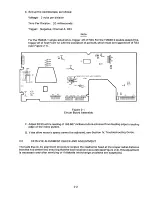

READY

INDEX SENSOR

L.E.D.'S ~

CONTROL

LOGIC

INDEX

DISK CHANGE

TWO SIDED

D.C.

STEPPER

MOTOR

WRITE PROTECT

TRACK 00

WRITE PROTECT

SENSOR

+

L.E.D.

IN USE

INDEX DETECTORS

SIDE SELECT

HEAD CARRIAGE

AND STEPPER

BAND

ASSEMBLY

WR ITE

PROTECT

DETECTOR

DRIVE SELECT

SPINDLE

MOTOR

CONTROL

M OTOR CONTRO L

D.C. DRIVE

MOTOR

WRITE GATE

WRITE DATA

WRITE

LOGIC

CURRENT SWITCH

READ

LOGIC

READ DATA

DIRECTION

STEPPER

MOTOR

CONTROL

STEP

Figure 1-2

TM848 Disk Drive Functional Block Diagram

1.15 4

Po s i t i o ne r Control

The head positioning system uses a bipolar-driven motor drive, which changes one phase for each

track advancement of the read/write carriage. In addition to the logic necessary for motor control, a

gate is provided that inhibits positioner motion during a write operation.

1.15.5

Data E l e c t r o n ics

Information can be recorded on the diskette by using a double-frequency code. Figure 1-3 illustrates

the magnetization profiles in each bit cell for the number sequence shown for FM recording.

1-9

Содержание TM848-1

Страница 32: ...HUB CENTER LINE TRACK 0 TRACK 38 TRACK 76 Figure 2 2 Hub Center Line and Track Locations 2 3 ...

Страница 81: ...APPENDIX I PRINTED CIRCUIT BOARD S CHEM A T ICS AND ASSEM B LY DRAW IN G S ...

Страница 88: ...APPENDIX II RECOM M E N D E D SPARE PARTS LIST ...

Страница 90: ...Pi N 1 79031 001 1 082 ...