3 Product Description

C-863.12 Mercury Controller

MS249E

Version: 1.2.1

21

3.5.9

Servo Algorithm and Other Control Value Corrections

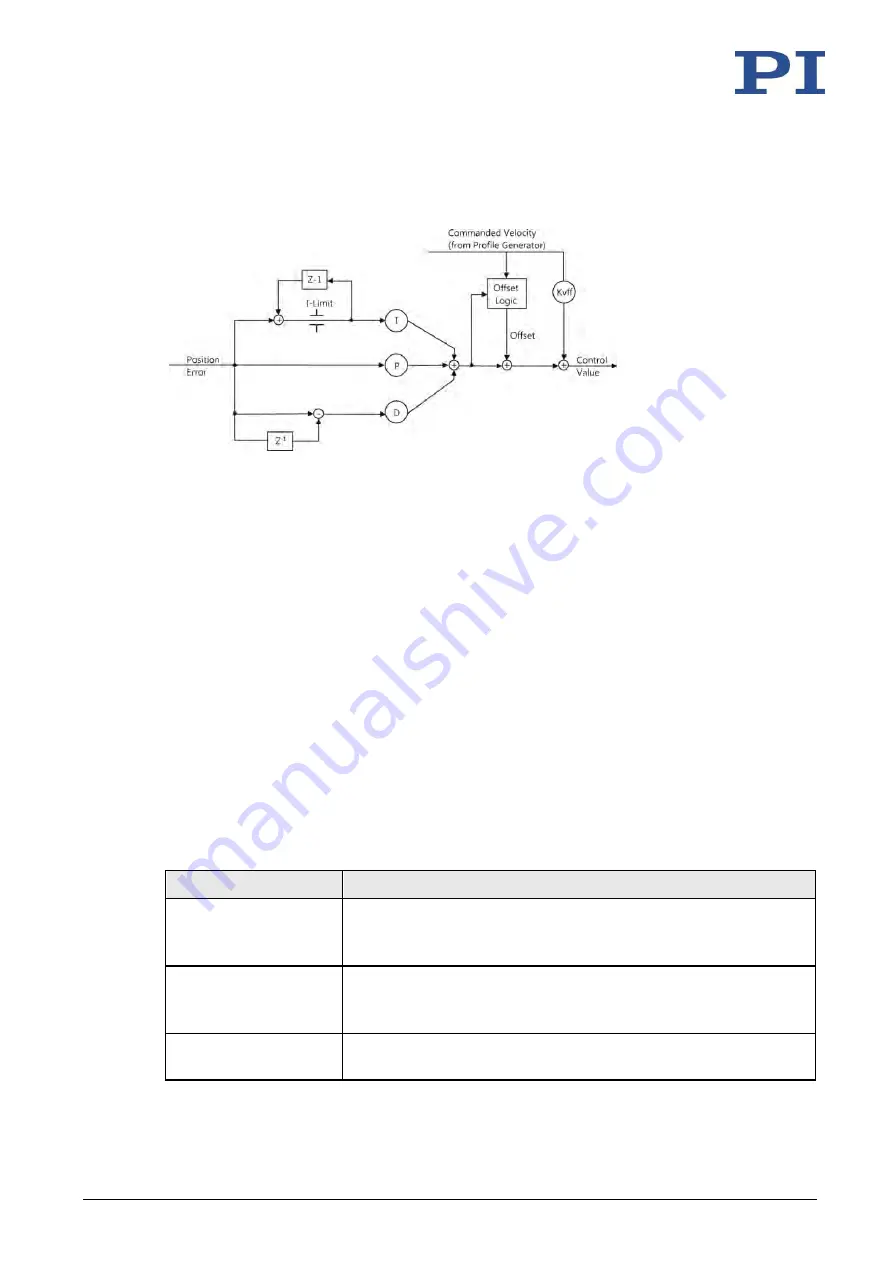

Figure 7: PID algorithm, offset correction and feed-forward control of the velocity (KVff); the notch filter

is not shown here

In closed-loop operation, the control value for the PWM converter integrated in the C-863.12

and therefore the settling behavior of the system is optimized via the following corrections:

▪

Servo algorithm: The position error, which results from the difference between the

calculated dynamics profile (see "Generation of Dynamics Profile" (p. 18)) and the

actual position (sensor feedback), runs through a PID servo algorithm (

p

roportional

i

ntegral

d

erivative).

▪

Dynamics profile corrections: The dynamics profile generated can be subject to an

offset correction and a feed-forward control of the velocity.

Regardless of the operating mode, the control value can be subjected to an additional

correction via the notch filter.

Servo algorithm

The servo algorithm uses the following servo control parameters. The optimum servo control

parameter setting depends on your application and your requirements; see "Optimizing Servo

Control Parameters" (p. 66).

Parameters

Description and Possible Values

P Term

0x411

Proportional constant (dimensionless)

0 to 32767

Aim: Rapid correction of the position error

I Term

0x412

Integration constant (dimensionless)

0 to 32767

Objective: Reduction of static position error

D Term

0x413

Differential constant (dimensionless)

0 to 32767