Installation

26

5.

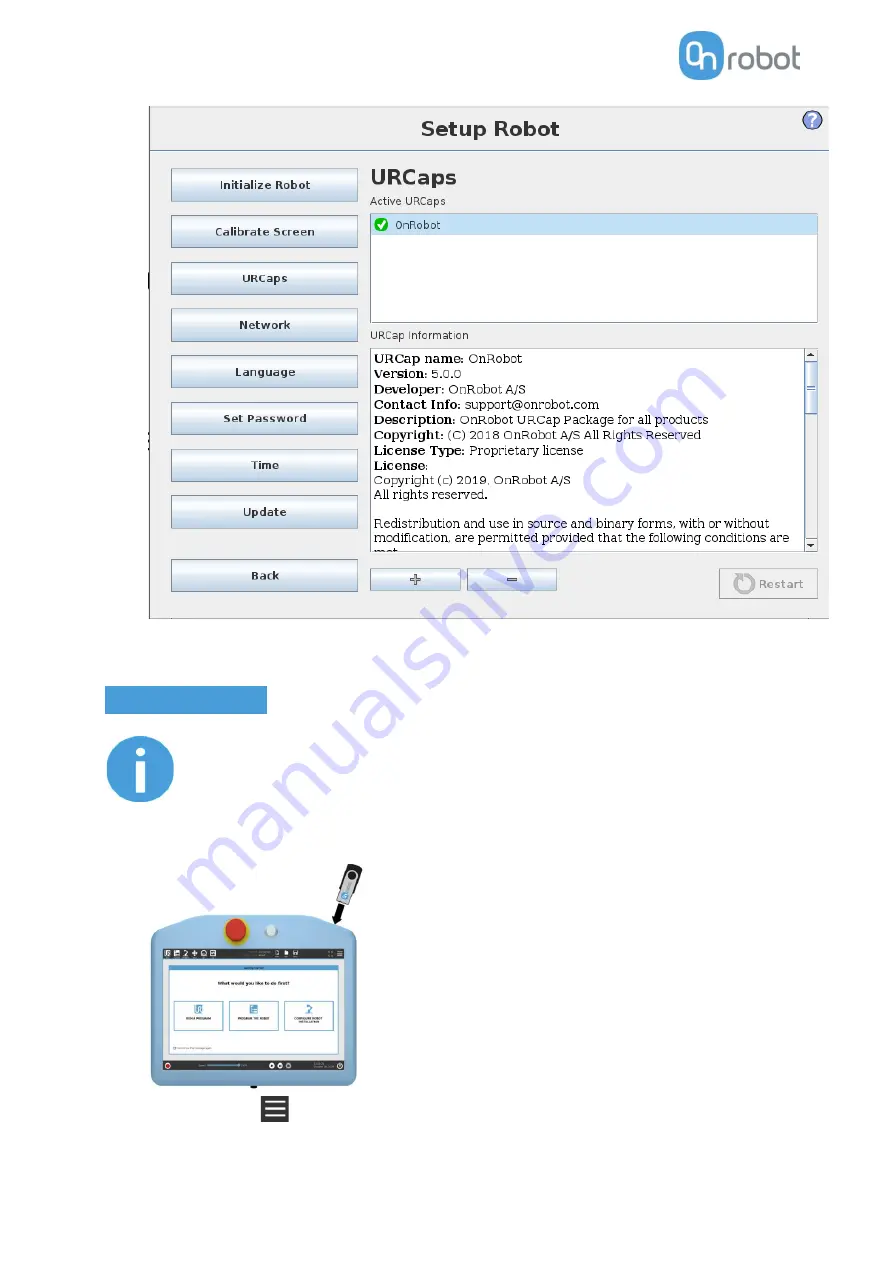

Initialize the robot.

UR e-Series

NOTE:

The minimum UR PolyScope version is

5.4

. Please remove all previous

OnRobot URCap version(s) before the installation.

1.

Insert the OnRobot USB drive in the USB slot on the top right side of the Teach Pendant.

2.

Then tap on the

menu (top right corner of the screen), then from the

System

section tap on

the

URCaps

menu.

Содержание VGC10

Страница 1: ...USER MANUAL FOR UR ROBOTS ORIGINAL INSTRUCTION EN v1 05...

Страница 28: ...Installation 28 5 Initialize the robot...

Страница 152: ...Hardware Specification 152 RG2 FT GrippingSpeedGraph GripperWorkingRange The dimensionsare in millimeters...

Страница 156: ...Hardware Specification 156 RG2 GrippingSpeedGraph RG2 Work Range...

Страница 159: ...Hardware Specification 159 RG6 GrippingSpeedGraph RG6 Work Range...

Страница 185: ...Hardware Specification 185 Gecko All dimensionsare in mm and inches...

Страница 186: ...Hardware Specification 186 RG2 FT All dimensionsare in mm and inches...

Страница 187: ...Hardware Specification 187 RG2 All dimensionsare in mm and inches...

Страница 188: ...Hardware Specification 188 RG6 All dimensionsare in mm and inches...

Страница 189: ...Hardware Specification 189 VG10 All dimensionsare in mm and inches...

Страница 190: ...Hardware Specification 190 All dimensionsare in mm and inches...

Страница 191: ...Hardware Specification 191 VGC10 All dimensionsare in mm and inches...

Страница 192: ...Hardware Specification 192 All dimensionsare in mm and inches...

Страница 193: ...Hardware Specification 193 Quick Changer Tool side All dimensionsare in mm and inches...

Страница 200: ...Certifications 200 10 Certifications...

Страница 201: ...Certifications 201...

Страница 202: ...Certifications 202...

Страница 203: ...Certifications 203...

Страница 204: ...Certifications 204...

Страница 205: ...Certifications 205...