BenchMike Pro Instruction Handbook: Introduction

1-5

1.5.2

Measuring Transparent

Products

The BenchMike Pro can measure transparent products when

a Transparent Object Measurement type (Types 51, 52, and

53) is selected. See section in Setup about

Although an opaque product blocks laser light across its en-

tire diameter, a transparent product allows some laser light

to pass through.

Since the BenchMike Pro determines product size based on the sharp increases and decreases in gathered laser

light, it may incorrectly determine product diameter for transparent products unless Transparent Object Measure-

ment types are selected.

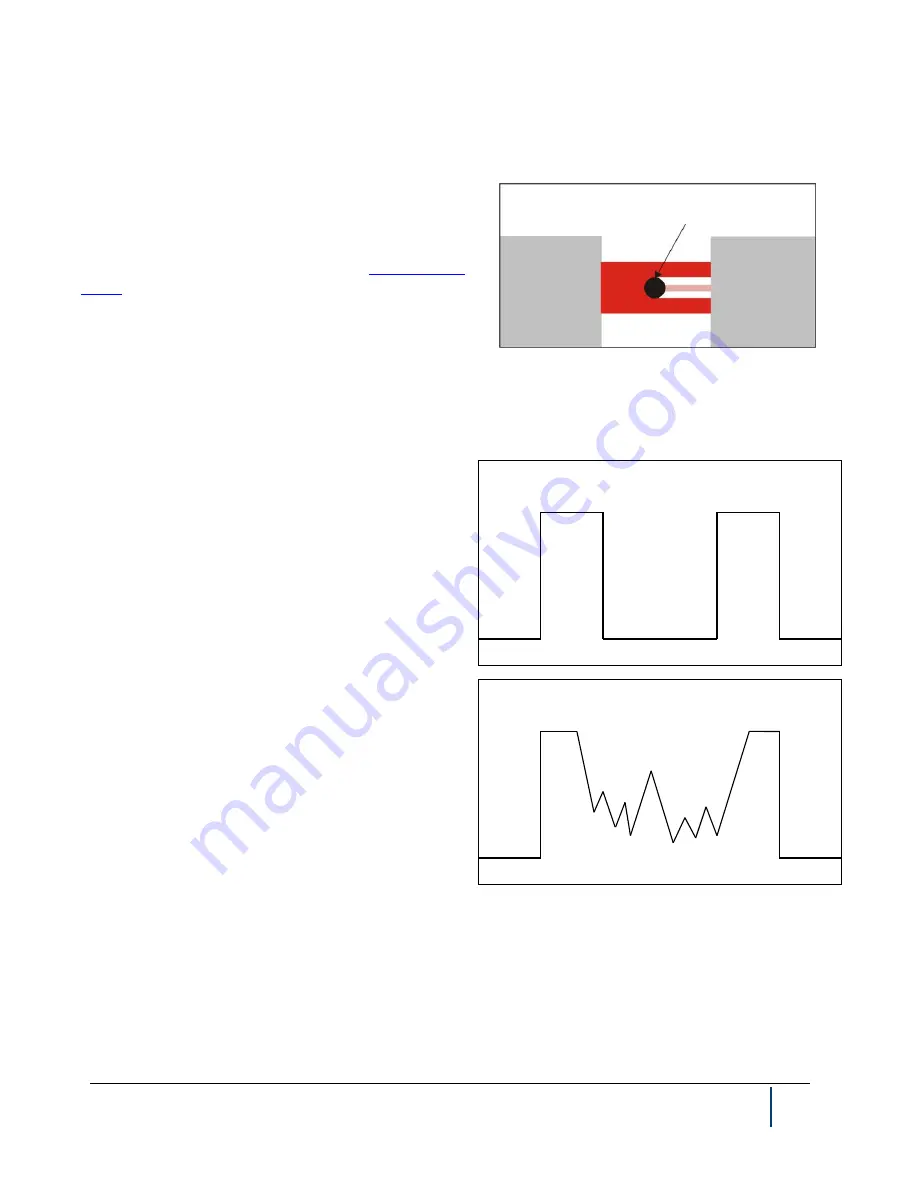

The drawings to the right show sample oscilloscope

waveforms from the measurement of an opaque product

and a transparent product. For the opaque product, the

BenchMike Pro can easily determine the width of the

product since the waveform drops sharply and rises

sharply at the edges of the product. For the transparent

product, however, laser light passes through the product

and the behavior of the light between the first sharp drop

and last sharp rise must be ignored. With the Transpar-

ent Object Measurement type, the product diameter is

based on the first sharp drop in laser light and the last

sharp rise, resulting in a correct calculation of the diame-

ter.

Note that having a clean product is essential for attaining

an accurate measurement in these modes.

Transparent product

Oscilloscope waveform for opaque product

Oscilloscope waveform for transparent product

Содержание BenchMike Pro 2025

Страница 4: ......

Страница 14: ......

Страница 22: ......

Страница 40: ...2 18 BenchMike Pro Instruction Handbook Installation 11 Select a Make of Raw then select Add printer ...

Страница 44: ...2 22 BenchMike Pro Instruction Handbook Installation 20 Verify the report ...

Страница 50: ...2 28 BenchMike Pro Instruction Handbook Installation 10 Choose the Raw Make then click Continue ...

Страница 51: ...BenchMike Pro Instruction Handbook Installation 2 29 11 Choose the Raw Queue en Model then click Add Printer ...

Страница 112: ......

Страница 150: ......

Страница 156: ......

Страница 160: ...BenchMike Pro Instruction Handbook Index Units 4 25 Universal Slide Fixture 3 3 Ventilation Requirements 2 1 ...