Belt Tension

NOTE:

This procedure requires a specific Melco force gauge (p/n 995585-01), for

proper adjustment.

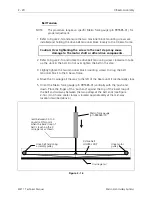

1. Refer to Figure 2-14 and ensure the two tensioner block mounting screws are

installed and holding the drive belt tensioner block loosely to the X beam frame.

Caution: Over tightening the screw in the next step may cause

damage to the motor shaft or other drive components.

2. Refer to Figure 2-14 and rotate the drive belt tensioning screw clockwise to take

up the slack in the belt. Do not over tighten the belt in this step.

3. Slightly tighten the two tensioner block mounting screws to snug the belt

tensioner block to the X beam frame.

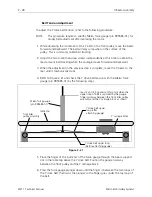

4. Move the X carriage all the way to the left of the beam until it mechanically stops.

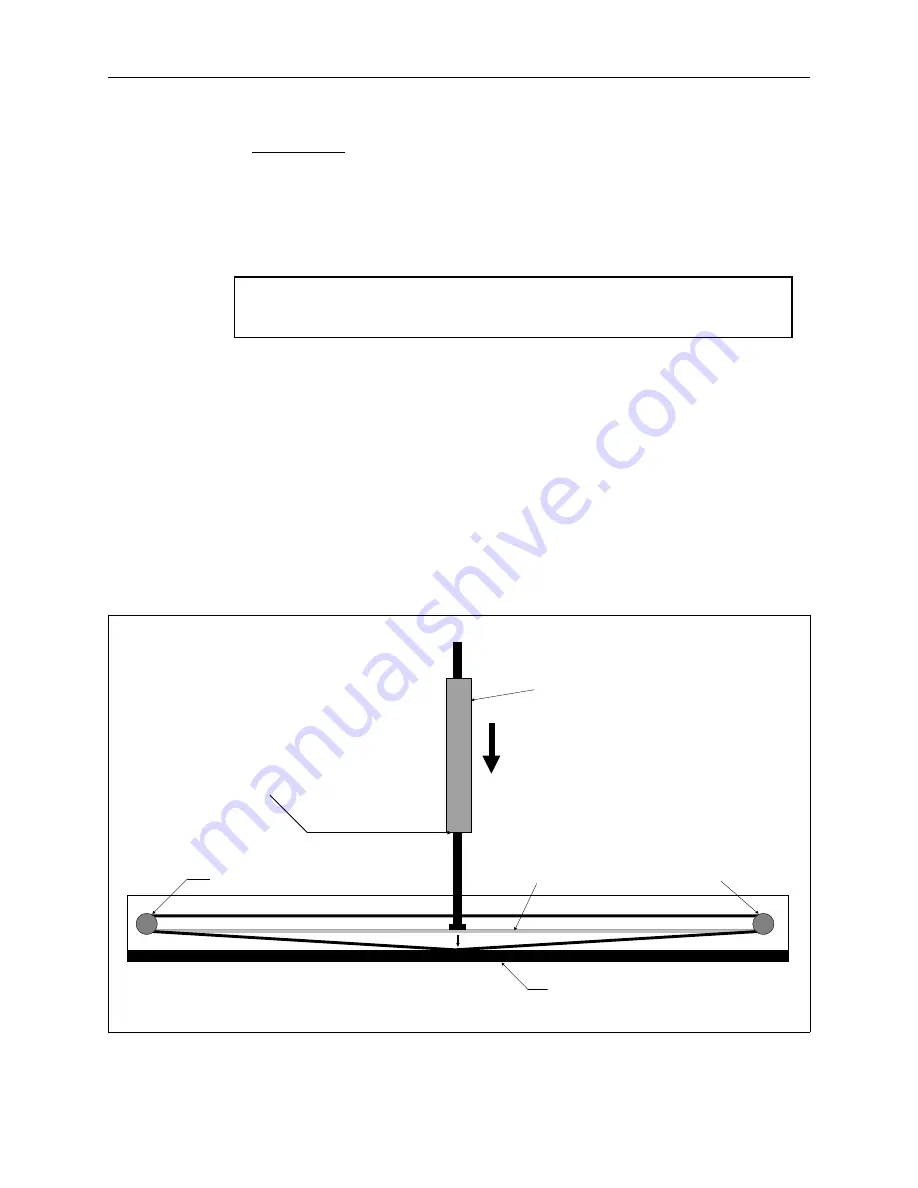

5. Orient the Melco force gauge (p/n 995585-01) vertically with the ’push end’

down. Place the finger of the ’push end’ against the top of the lower loop of

the belt and mid-way between the two pulleys at the belt ends (see Figure

2-16). (An X home cable clamps is located approximately at the mid-way

location described above.)

read between 3.5 to 4

pounds at this point

when the lower loop of

belt is touching the X

carriage rail as shown

Melco force gauge

(p/n 995585-01)

drive motor

pulley

X carriage rail

drive belt tensioning

assembly pulley

X drive belt

LOWER LOOP

Figure 2 - 16

2 - 20

X Beam Assembly

EMT 1 Technical Manual

Melco Embroidery Systems

Содержание EMT 1

Страница 6: ...This page intentionally left blank Table of Contents 110344 01 Revision B iv EMT 1 Technical Manual ...

Страница 44: ...This page intentionally left blank 2 30 X Beam Assembly EMT 1 Technical Manual Melco Embroidery Systems ...

Страница 74: ...This page intentionally left blank 3 30 Rotary Hook EMT 1 Technical Manual Melco Embroidery Systems ...