Use only high-quality electronic-grade isopropyl alcohol of at least 90 percent concentration as a cleaning solvent.

The isopropyl mixture must consist of alcohol and distilled water only.

Use only nonabrasive, lint-free cloths, and/or swabs to clean the tape path.

Follow these precautions:

Do not use cleaner solutions that contain lubricants. Lubricants leave a deposit on the tape head and impair

performance.

Do not use alcohol cleaning solutions on the rubber gripping fingers on the takeup reel.

Do not use aerosol cleaners. The spray is difficult to control and often contains metallic particles that can

damage the tape head.

Do not use soap and water on the tape path. Soap leaves a thick film, and water may damage electronic parts.

Discard used cloths and swabs after use. Even if they appear clean, they are contaminated.

Do not use facial tissues. Although they may seem effective, they leave highly abrasive lint in the tape path.

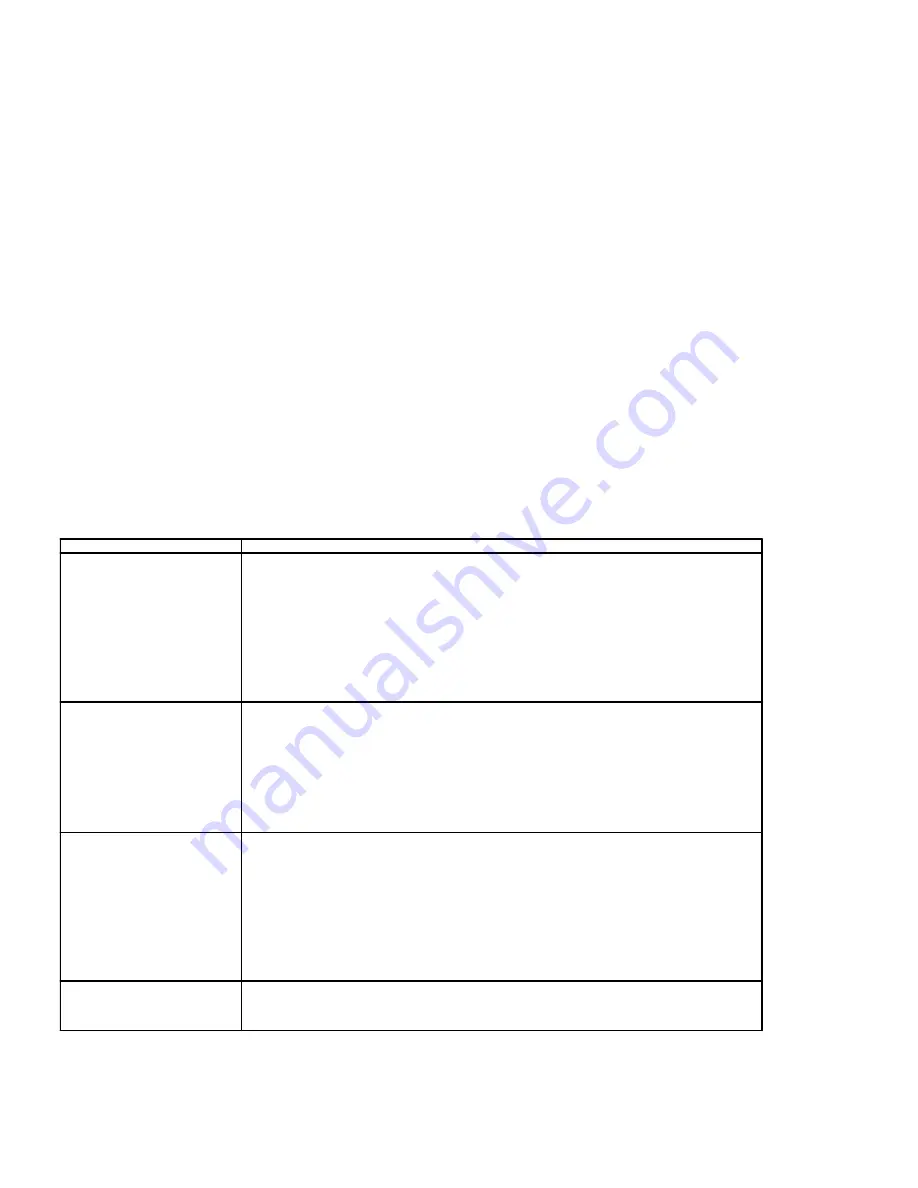

Table 11.36.3-1 indicates the cleaning criteria for the KS-23909, L21 9-track tape drive.

Table 11.36.3-1 Cleaning Schedule Guidelines

CLEANING LEVEL

CLEANING CRITERIA

MINIMUM

Clean the tape path thoroughly EVERY 8 HOURS if:

Less than ten reels are used in 8 hours.

You see no particles on the tape head after each reel of tape.

You do not suspect abnormal dust (from increased traffic or vacuuming) in the room

where the drive is located.

NORMAL

Clean the tape path thoroughly EVERY 1 TO 2 HOURS of continuous running if:

More than ten reels are used in 8 hours.

You see no particles on the tape head after each reel of tape.

You do not suspect abnormal dust in the room where the drive is located.

HEAVY

Clean the tape thoroughly AFTER EACH REEL of tape if:

Particles appear on the tape head after each reel of tape.

You are reading interchange tapes from outside the clean room.

You are using new or seldom-used tapes (new tapes usually contain debris, generated

during their manufacture, from the slitting process).

SPECIAL

Clean the tape path ANYTIME you suspect abnormal dust in the room where the drive is

located. This condition may be caused by custodial activity, equipment moves, or supply

delivery. Also, clean the tape path if the drive has not been used for several days.

235-105-210

October 1999

Copyright © 1999

Page 5

Содержание 5ESS-2000

Страница 96: ...235 105 210 October 1999 Copyright 1999 Page 2 ...

Страница 184: ...235 105 210 October 1999 Copyright 1999 Page 3 ...

Страница 300: ...13 STOP YOU HAVE COMPLETED THIS PROCEDURE 235 105 210 October 1999 Copyright 1999 Page 55 ...

Страница 339: ...7 STOP YOU HAVE COMPLETED THIS PROCEDURE 235 105 210 October 1999 Copyright 1999 Page 13 ...

Страница 342: ...235 105 210 October 1999 Copyright 1999 Page 2 ...

Страница 359: ...235 105 210 October 1999 Copyright 1999 Page 5 ...

Страница 516: ...Figure 10 24 1 KS 23483 L13 Disk Drive Cable Connection Rear View 235 105 210 October 1999 Copyright 1999 Page 2 ...

Страница 517: ...Figure 10 24 2 KS 23483 L21 Disk Drive Cable Connection Rear View 235 105 210 October 1999 Copyright 1999 Page 3 ...

Страница 518: ...Figure 10 24 3 KS 23841 L15 Disk Drive Cable Connection Rear View 235 105 210 October 1999 Copyright 1999 Page 4 ...

Страница 523: ...Figure 10 24 6 Top View of DUP Showing Internal Cabling 235 105 210 October 1999 Copyright 1999 Page 9 ...

Страница 609: ...2 STOP YOU HAVE COMPLETED THIS PROCEDURE 235 105 210 October 1999 Copyright 1999 Page 12 ...

Страница 628: ...a SM inhibited Response OK 2 STOP YOU HAVE COMPLETED THIS PROCEDURE 235 105 210 October 1999 Copyright 1999 Page 8 ...

Страница 653: ...Response OK 2 STOP YOU HAVE COMPLETED THIS PROCEDURE 235 105 210 October 1999 Copyright 1999 Page 16 ...

Страница 676: ...235 105 210 October 1999 Copyright 1999 Page 9 ...

Страница 792: ...3 STOP YOU HAVE COMPLETED THIS PROCEDURE 235 105 210 October 1999 Copyright 1999 Page 9 ...

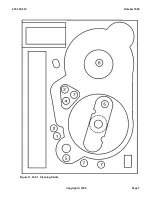

Страница 799: ...Figure 11 36 3 1 Cleaning Points 235 105 210 October 1999 Copyright 1999 Page 7 ...

Страница 801: ...235 105 210 October 1999 Copyright 1999 Page 9 ...

Страница 839: ...2 STOP YOU HAVE COMPLETED THIS PROCEDURE 235 105 210 October 1999 Copyright 1999 Page 16 ...

Страница 999: ...2 STOP YOU HAVE COMPLETED THIS PROCEDURE 235 105 210 October 1999 Copyright 1999 Page 13 ...

Страница 1008: ...Figure 11 55 1 CTSNS DIP Switch Settings 235 105 210 October 1999 Copyright 1999 Page 2 ...

Страница 1011: ...235 105 210 October 1999 Copyright 1999 Page 5 ...

Страница 1053: ...235 105 210 October 1999 Copyright 1999 Page 15 ...

Страница 1165: ...Procedure 14 14 RESERVED FOR FUTURE USE PROCEDURE 1 Reserved For future use 235 105 210 October 1999 Copyright 1999 Page 1 ...

Страница 1186: ...Procedure 14 17 RESERVED FOR FUTURE USE PROCEDURE 1 Reserved For future use 235 105 210 October 1999 Copyright 1999 Page 1 ...

Страница 1187: ...Procedure 14 18 RESERVED FOR FUTURE USE PROCEDURE 1 Reserved For future use 235 105 210 October 1999 Copyright 1999 Page 1 ...

Страница 1284: ...Figure 15 15 1 PARADYNE Paradyne Corporation 3810 Modem Diagnostic Control Panel 235 105 210 October 1999 Copyright 1999 Page 6 ...

Страница 1287: ...Figure 15 16 1 153A Adapter Connection Figure 15 16 2 AMATPS Block Diagram 235 105 210 October 1999 Copyright 1999 Page 3 ...

Страница 1289: ...Figure 15 17 2 AMATPS Data Link 235 105 210 October 1999 Copyright 1999 Page 2 ...

Страница 1290: ...Figure 15 17 3 Single Housing B25A Cable Assembly 235 105 210 October 1999 Copyright 1999 Page 3 ...

Страница 1292: ...235 105 210 October 1999 Copyright 1999 Page 5 ...

Страница 1294: ...Figure 15 17 8 201C to TN82 Data Set Cable Drawing 235 105 210 October 1999 Copyright 1999 Page 7 ...

Страница 1303: ...9 STOP YOU HAVE COMPLETED THIS PROCEDURE 235 105 210 October 1999 Copyright 1999 Page 2 ...

Страница 1324: ...11 Type and enter q 12 STOP YOU HAVE COMPLETED THIS PROCEDURE 235 105 210 October 1999 Copyright 1999 Page 2 ...

Страница 1342: ...Figure 15 40 1 SCANS II Dial Up Data Set Installation Diagram 235 105 210 October 1999 Copyright 1999 Page 2 ...

Страница 1344: ...Figure 15 40 4 59A1 Mounting Front in Slot J3 Figure 15 40 5 2048A Data Set Front 235 105 210 October 1999 Copyright 1999 Page 4 ...

Страница 1345: ...Figure 15 40 6 Berg Connector Terminations and Layout 235 105 210 October 1999 Copyright 1999 Page 5 ...

Страница 1346: ...Figure 15 40 7 B25A Cable 4 STOP YOU HAVE COMPLETED THIS PROCEDURE 235 105 210 October 1999 Copyright 1999 Page 6 ...

Страница 1360: ...Figure 15 47 2 Typical SCANS III Link Diagram 235 105 210 October 1999 Copyright 1999 Page 2 ...

Страница 1368: ...Response FA or OK appears 17 STOP YOU HAVE COMPLETED THIS PROCEDURE 235 105 210 October 1999 Copyright 1999 Page 2 ...

Страница 1372: ...235 105 210 October 1999 Copyright 1999 Page 2 ...

Страница 1374: ...235 105 210 October 1999 Copyright 1999 Page 4 ...

Страница 1376: ...Figure 15 55 6 201C to TN83 Data Set Cable Drawing 235 105 210 October 1999 Copyright 1999 Page 6 ...

Страница 1418: ...Figure 15 56 1 PARADYNE 3810 Modem Diagnostic Control Panel 235 105 210 October 1999 Copyright 1999 Page 4 ...

Страница 1421: ...Table 1 1 O M Checklist 235 105 210 October 1999 Copyright 1999 Page 3 ...