2NP-6

1-5-31

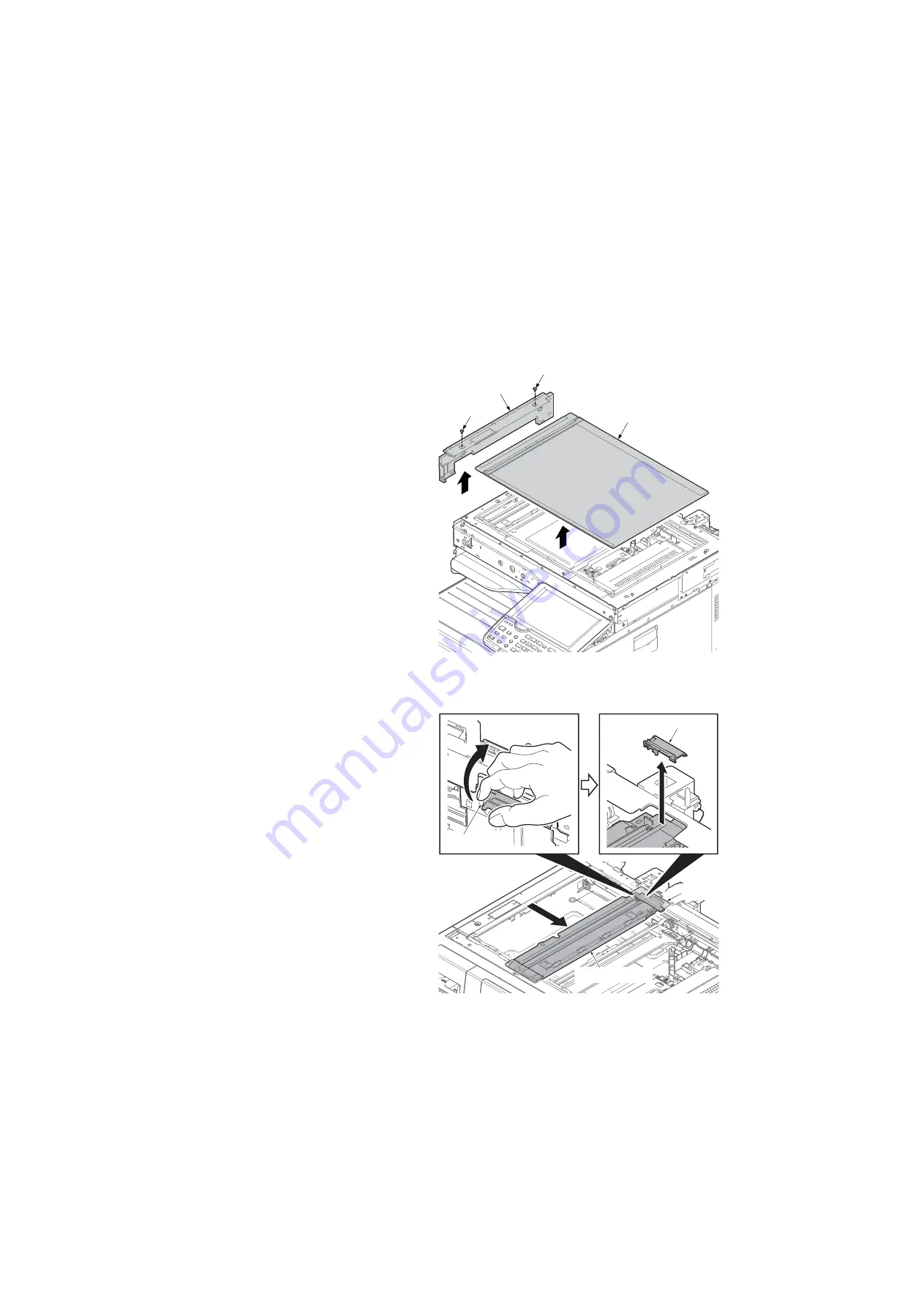

(7) Detaching and refitting the scanner wires

Follow the Procedures below when the scanner wires are broken or to be replaced.

(7-1) Detaching the scanner wires

Procedures

1. Remove the scanner unit.

2. Remove the two screws.

3. Remove the scanner left cover and the

contact glass assy.

Figure 1-5-56

4. Move the exposure unit to the cutout

portion.

5. Peel off the sheet.

6. Release the hook and then remove the

FFC cover.

Figure 1-5-57

Screw

Screw

Scanner

left cover

Contactglass assy

FFC cover

Exposure unit

Hook

Sheet

Содержание TASKalfa 2551ci

Страница 1: ...SERVICE MANUAL Published in September 2016 842NP11A 2NPSM06A Rev A TASKalfa 2551ci ...

Страница 10: ...This page is intentionally left blank ...

Страница 97: ...2NP 1 1 2 74 This page is intentionally left blank ...

Страница 259: ...2NP 1 3 162 U486 Details on the modes Figure 1 3 47 Item No Description ...

Страница 473: ...2NP 1 5 62 This page is intentionally left blank ...

Страница 496: ...2NP 2 1 21 Figure 2 1 25 Duplex conveying section block diagram EPWB DU_SW DU_CL_REM YC25 3 YC24 3 DUCL DUS ...

Страница 497: ...2NP 2 1 22 This page is intentionally left blank ...

Страница 544: ...2NP 2 3 37 2 3 5 IH PWB Figure 2 3 5 IH PWB silk screen diagram YC1 1 2 YC8 1 3 YC6 2 1 YC4 6 1 YC3 YC10 YC9 ...

Страница 555: ...2NP 2 3 48 This page is intentionally left blank ...

Страница 584: ...Installation Guide DP 770 B Document processor DP 772 Document processor Installation Guide ...

Страница 620: ...DP 773 Document processor Installation Guide ...

Страница 646: ...PF 791 500 x 2 Paper feeder Installation Guide ...

Страница 654: ...PF 810 3000 sheets deck Installation Guide ...

Страница 667: ...DF 770 D Document finisher Installation Guide ...

Страница 685: ...AK 740 Bridge unit Installation Guide ...

Страница 687: ...PH 7A C D Punch unit Installation Guide ...

Страница 708: ...DT 730 B Document tray Installation Guide ...

Страница 710: ...5 2013 5 302LC56750 01 H F G D D 6 4 3 7 E C D D M4 8 M4 8 M4 8 M4 8 ...

Страница 711: ...FAX System W B Installation Guide ...