SECTION 5 - BASIC HYDRAULIC INFOR

M

ATION AND SCHE

M

ATICS

5-92

3121160

6.

To assemble cradle sub-assembly, install bushing onto

cradle retaining with button head capscrews. Torque

button head capscrew 14 to 16 in. lbs. (1.6 to 1.8 Nm).

7.

Place cradle sub-assembly into housing making sure

cradle is completely seated into housing. Retain cradle

sub-assembly with two capscrews. Torque capscrews 20

to 24 ft. lbs (27 to 33 Nm).

8.

To install shaft, place exterior retaining ring, thrust race,

thrust bearing, second thrust race, and second retaining

ring onto shaft. Position washer and shaft seal or spacer

onto shaft.

9.

Install shaft assembly into front of housing for units with

spacer, retain with interior retaining ring and go on to

step 10. For units with shaft seal. seat seal into position

with seal driver and retain with interior retaining ring.

10.

Install servo piston follower onto swashplate dowel pin.

Install swashplate carefully onto bushing (coat bushing

surface with hydraulic oil), aligning servo piston follower

with slot in servo piston assembly.

NOTE:

Refer to “Rotating Kit Assembly” for reassembly of rotating

kit assembly.

11.

To install rotating kit assembly, leave housing and shaft

in the horizontal position. Holding swashplate into posi-

tion with screw driver through controller linkage pas-

sageway at the top of housing. place rotating kit

assembly over shaft and into housing until pistons are in

against swashplate. Make sure all parts are in housing

completely and properly positioned. Return the pump

to the vise with open end of housing up, clamping hous-

ing on the outer portion of the flange.

12.

Install gasket on to housing.

13.

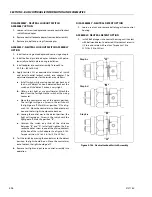

If necessary, press new bearing and roll pin in endcover

to dimension shown in figure 1-3. Bearing installed with

the numbered end outward. Roll pin installed with split

oriented away from bearing.

14.

Install new o-ring on relief valves. Install relief valve in its

original cavity in endcover that it was removed. Torque

100 to 110 ft. lbs (136 to 149 Nm).

15.

Install new o-ring on bypass valve or plug. Install bypass

valve or plug into endcover.

NOTE:

Make sure paddle of bypass valve is perpendicular to relief

valve axis prior to installing or damage could result.

16.

Apply a small amount of petroleum jelly to the steel side

of valve plate to hold in place for installation. Aligning

the index pin, place the valve plate in position onto the

endcover, with steel side against endcover.

17.

Install endcover assembly onto housing assembly. Make

sure ports are positioned correctly, valve plate and gas-

ket stay in place.

18.

Install key and inner ring gerotor onto shaft or coupler

assembly. Lubricate inner ring gerotor.

NOTE:

Refer to “Charge Pump Adapter Assembly” for assembly of

charge relief valve in adapter plate.

19.

Install o-ring and outer ring gerotor onto adapter plate.

Lubricate both a-ring and outer ring to hold in position

during assembly of adapter plate. Install adapter plate

onto endcover. Make sure o-ring and gerotor ring stay in

place.

20.

Retain endcover and adapter plate (when used) with

four capscrews, Torque 27 to 31 ft. lbs (37 to 42 Nm).

NOTE:

Refer to “Manual Servo Control Basic Assembly” for reas-

sembly of manual servo control assembly.

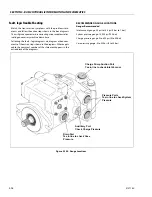

21.

Install control housing gasket onto housing. Install ori-

fices into control assembly and retain in position with

petroleum jelly. Position the feedback link at 90 degrees

from control housing. Install manual servo control

assembly onto housing making sure feedback link

entered small groove in servo piston assembly.

22.

Retain control assembly with six capscrews, torque 40 to

48 in. lbs (4.5 to 5.4 Nm).

23.

Install control arm onto control assembly input arm.

Retain with lock washer and nut, torque 4 to 6 ft. lbs

(5 to 8 Nm).

24.

Install new o-rings on all plugs. Install plugs into hous-

ing. Torque 3/4 in. plug 21 to 24 ft. lbs (28 to 32 Nm).

Torque 1-1/4 in. plug 40 to 45 ft. lbs (54 to 61 Nm).

25.

Содержание 740AJ

Страница 1: ...Service and Maintenance Manual Model 740AJ Prior to S N 0300185827 P N 3121160 October 24 2017 AS NZS...

Страница 2: ......

Страница 51: ...SECTION 2 GENERAL 3121160 2 11 Figure 2 2 Engine Operating Temperature Specifications Ford 4150548 E...

Страница 55: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 3 This page left blank intentionally...

Страница 56: ...SECTION 3 CHASSIS TURNTABLE 3 4 3121160 1 Figure 3 2 Axle and Steering Installation Sheet 1 of 2 0258286 C...

Страница 100: ...SECTION 3 CHASSIS TURNTABLE 3 48 3121160 Figure 3 37 Swing Bearing Tolerance Boom Placement Sheet 1 of 2...

Страница 101: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 49 Figure 3 38 Swing Bearing Tolerance Boom Placement Sheet 2 of 2...

Страница 116: ...SECTION 3 CHASSIS TURNTABLE 3 64 3121160 Figure 3 44 Swing Hub Prior to SN 0300074383...

Страница 124: ...SECTION 3 CHASSIS TURNTABLE 3 72 3121160 Figure 3 45 Swing Drive Hub Fairfield SN 0300074383 through 0300134352...

Страница 180: ...SECTION 3 CHASSIS TURNTABLE 3 128 3121160 1 Figure 3 66 Auxiliary Pump Location 1 AuxiliaryPump 2 HydraulicTank...

Страница 203: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 151 Figure 3 77 EFI Component Location...

Страница 206: ...SECTION 3 CHASSIS TURNTABLE 3 154 3121160 Figure 3 78 ECM EPM Identification ECM EPM...

Страница 213: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 161 Megajector Regulator LockoffSolenoid Figure 3 80 LPG System Components Mixer...

Страница 219: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 167 Figure 3 81 Check Out and Initial Start Up Procedures...

Страница 224: ...SECTION 3 CHASSIS TURNTABLE 3 172 3121160 Figure 3 83 Deutz EMR 2 Troubleshooting Flow Chart...

Страница 225: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 173 Figure 3 84 Deutz EMR 2 Vehicle Side Connection Diagram...

Страница 226: ...SECTION 3 CHASSIS TURNTABLE 3 174 3121160 Figure 3 85 Deutz EMR 2 Engine Side Connection Diagram Sheet 1 of 2...

Страница 227: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 175 Figure 3 86 Deutz EMR 2 Engine Side Connection Diagram Sheet 2 of 2...

Страница 228: ...SECTION 3 CHASSIS TURNTABLE 3 176 3121160 Figure 3 87 EMR 2 Engine Plug Pin Identification...

Страница 229: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 177 Figure 3 88 EMR 2 Vehicle Plug Pin Identification...

Страница 230: ...SECTION 3 CHASSIS TURNTABLE 3 178 3121160 Figure 3 89 EMR2 Fault Codes Sheet 1 of 5...

Страница 231: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 179 Figure 3 90 EMR2 Fault Codes Sheet 2 of 5...

Страница 232: ...SECTION 3 CHASSIS TURNTABLE 3 180 3121160 Figure 3 91 EMR2 Fault Codes Sheet 3 of 5...

Страница 233: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 181 Figure 3 92 EMR2 Fault Codes Sheet 4 of 5...

Страница 234: ...SECTION 3 CHASSIS TURNTABLE 3 182 3121160 Figure 3 93 EMR2 Fault Codes Sheet 5 of 5...

Страница 303: ...SECTION 4 BOOM PLATFORM 3121160 4 31 Figure 4 20 Rotator Assembly HELAC...

Страница 335: ...SECTION 4 BOOM PLATFORM 3121160 4 63 THIS SENSOR ON NON ADE MACHINES ONLY Figure 4 27 UMS Sensor Location...

Страница 336: ...SECTION 4 BOOM PLATFORM 4 64 3121160 Figure 4 28 UMS Module Location ADE MACHINES NON ADE MACHINES...

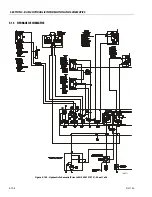

Страница 425: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 3121160 5 81 Figure 5 131 Variable Displacement Pump Rexroth...

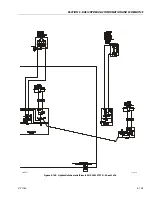

Страница 443: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 3121160 5 99 Figure 5 146 Fault Logic Troubleshooting...

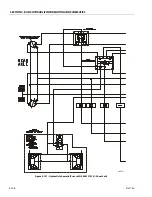

Страница 444: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 5 100 3121160 Figure 5 147 Fault Logic Troubleshooting...

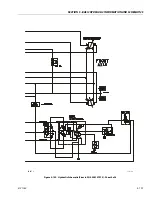

Страница 445: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 3121160 5 101 Figure 5 148 Fault Logic Troubleshooting...

Страница 460: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 5 116 3121160 NOTES...

Страница 467: ...SECTION 6 JLG CONTROL SYSTEM 3121160 6 7 Figure 6 2 ADE Block Diagram...

Страница 471: ...SECTION 6 JLG CONTROL SYSTEM 3121160 6 11 Figure 6 6 Analyzer Flow Chart Prior to Version 5 X Software Sheet 4 of 4...

Страница 473: ...SECTION 6 JLG CONTROL SYSTEM 3121160 6 13 Figure 6 8 Analyzer Flow Chart Version 5 X Software Sheet 2 of 4...

Страница 534: ...SECTION 6 JLG CONTROL SYSTEM 6 74 3121160 NOTES...

Страница 545: ...SECTION 7 BASIC ELECTRICAL INFORMATION SCHEMATICS 3121160 7 11 Figure 7 15 Connector Installation...

Страница 580: ...SECTION 7 BASIC ELECTRICAL INFORMATION SCHEMATICS 7 46 3121160 NOTES...

Страница 581: ......