SECTION 5 - BASIC HYDRAULIC INFOR

M

ATION AND SCHE

M

ATICS

5-88

3121160

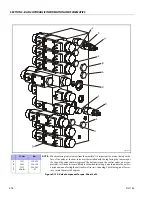

DISASSEMBLY

1.

Remove the four screws (C300) holding the control

housing onto the end cap.

2.

Remove the control and discard the three interface O-

rings (C200).

3.

Remove the Pressure Compensator set screw (C102),

Pressure Compensator adjustment screw (C138),O-ring

(C136), springs (C135, C134), and seat (C133). Discard

the o-ring.

4.

Remove the plug (C103), o-ring (C103A),and Pressure

Compensator spool (C132) from the control housing;

discard the o-ring. Note orientation of the spool for reas-

sembly.

5.

Remove the plug (C107) and o-ring (C107A); discard the

o-ring.

NOTE:

For Pressure Compensator only controls, skip steps 6 and 7.

6.

Remove the Load Sense set screw (C102), Load Sense

adjustment screw (C118), o-ring (C116), backup rings

(C117), springs (C114, C115), and seat (C113); discard the

o-ring.

7.

Remove the plug (C106), O-ring (C106A), and Load

Sense spool (C112) from the control housing; discard the

o-ring. Note orientation of the spool for reassembly.

INSPECTION

1.

Inspect the adjustment screws for wear at the tips and

where they contact the springs; replace as necessary

2.

Inspect the springs and spring guides for wear or dam-

age; replace as necessary.

3.

Carefully inspect the spools. Ensure the sealing lands are

free of nicks and scratches. Check the ends that contact

the spring guides for wear. Replace spools as necessary.

4.

Inspect the control housing for damage. Check the

spool bores for excessive wear.

5.

Clean all parts and lubricate spools, springs, guides and

new o-rings with clean hydraulic fluid.

REASSEMBLY

1.

Install the Pressure Compensator spool, spherical end

first, into the Pressure Compensator bore. The Pressure

Compensator spool is the shorter of the two. Using a

new o-ring, install the plug (C103). Torque to 8-10 ft. lbs.

(11-14 Nm).

2.

Place the two Pressure Compensator springs onto the

spring guide and install into the Pressure Compensator

bore. Place a new o-ring onto the Pressure Compensator

adjustment screw and thread it into the Pressure Com-

pensator bore until flush, then make another full turn.

Install and torque the set screw to 6-8 ft. lbs. (7-11 Nm).

NOTE:

For Pressure Compensator only controls, skip steps 15 and

16.

3.

Install the Load Sense spool, spherical end first, into the

Load Sense bore. The Load Sense spool is the longer of

the two. Using a new o-ring, install the plug (C106).

Torque to 8-10 ft. lbs. (11-14 Nm).

4.

Place the two Load Sense springs onto the spring guide

and install into the Load Sense bore. Place a new o-ring

and backup rings onto the Load Sense adjustment

screw and thread it into the Load Sense bore until flush,

then make another full turn. Install and torque the set

screw to 6-8 ft. lbs. (7-11 Nm).

5.

Using a new o-ring, install the plug (C107). Torque to 8-

10 ft. lbs. (11-14 Nm).

6.

Using petroleum jelly to retain them, install the three

interface o-rings (C200) in the recesses on the control

housing.

7.

Install the control assembly onto the endcap using the

four screws (C300). Torque to 11-13 ft. lbs.

(15-18 Nm). Torque screws in a criss-cross pattern and

re-torque the first screw to ensure proper torque reten-

tion.

8.

Check and adjust the control setting. See Adjustments.

Содержание 740AJ

Страница 1: ...Service and Maintenance Manual Model 740AJ Prior to S N 0300185827 P N 3121160 October 24 2017 AS NZS...

Страница 2: ......

Страница 51: ...SECTION 2 GENERAL 3121160 2 11 Figure 2 2 Engine Operating Temperature Specifications Ford 4150548 E...

Страница 55: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 3 This page left blank intentionally...

Страница 56: ...SECTION 3 CHASSIS TURNTABLE 3 4 3121160 1 Figure 3 2 Axle and Steering Installation Sheet 1 of 2 0258286 C...

Страница 100: ...SECTION 3 CHASSIS TURNTABLE 3 48 3121160 Figure 3 37 Swing Bearing Tolerance Boom Placement Sheet 1 of 2...

Страница 101: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 49 Figure 3 38 Swing Bearing Tolerance Boom Placement Sheet 2 of 2...

Страница 116: ...SECTION 3 CHASSIS TURNTABLE 3 64 3121160 Figure 3 44 Swing Hub Prior to SN 0300074383...

Страница 124: ...SECTION 3 CHASSIS TURNTABLE 3 72 3121160 Figure 3 45 Swing Drive Hub Fairfield SN 0300074383 through 0300134352...

Страница 180: ...SECTION 3 CHASSIS TURNTABLE 3 128 3121160 1 Figure 3 66 Auxiliary Pump Location 1 AuxiliaryPump 2 HydraulicTank...

Страница 203: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 151 Figure 3 77 EFI Component Location...

Страница 206: ...SECTION 3 CHASSIS TURNTABLE 3 154 3121160 Figure 3 78 ECM EPM Identification ECM EPM...

Страница 213: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 161 Megajector Regulator LockoffSolenoid Figure 3 80 LPG System Components Mixer...

Страница 219: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 167 Figure 3 81 Check Out and Initial Start Up Procedures...

Страница 224: ...SECTION 3 CHASSIS TURNTABLE 3 172 3121160 Figure 3 83 Deutz EMR 2 Troubleshooting Flow Chart...

Страница 225: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 173 Figure 3 84 Deutz EMR 2 Vehicle Side Connection Diagram...

Страница 226: ...SECTION 3 CHASSIS TURNTABLE 3 174 3121160 Figure 3 85 Deutz EMR 2 Engine Side Connection Diagram Sheet 1 of 2...

Страница 227: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 175 Figure 3 86 Deutz EMR 2 Engine Side Connection Diagram Sheet 2 of 2...

Страница 228: ...SECTION 3 CHASSIS TURNTABLE 3 176 3121160 Figure 3 87 EMR 2 Engine Plug Pin Identification...

Страница 229: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 177 Figure 3 88 EMR 2 Vehicle Plug Pin Identification...

Страница 230: ...SECTION 3 CHASSIS TURNTABLE 3 178 3121160 Figure 3 89 EMR2 Fault Codes Sheet 1 of 5...

Страница 231: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 179 Figure 3 90 EMR2 Fault Codes Sheet 2 of 5...

Страница 232: ...SECTION 3 CHASSIS TURNTABLE 3 180 3121160 Figure 3 91 EMR2 Fault Codes Sheet 3 of 5...

Страница 233: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 181 Figure 3 92 EMR2 Fault Codes Sheet 4 of 5...

Страница 234: ...SECTION 3 CHASSIS TURNTABLE 3 182 3121160 Figure 3 93 EMR2 Fault Codes Sheet 5 of 5...

Страница 303: ...SECTION 4 BOOM PLATFORM 3121160 4 31 Figure 4 20 Rotator Assembly HELAC...

Страница 335: ...SECTION 4 BOOM PLATFORM 3121160 4 63 THIS SENSOR ON NON ADE MACHINES ONLY Figure 4 27 UMS Sensor Location...

Страница 336: ...SECTION 4 BOOM PLATFORM 4 64 3121160 Figure 4 28 UMS Module Location ADE MACHINES NON ADE MACHINES...

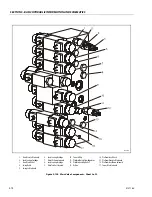

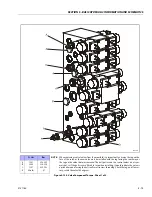

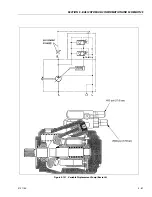

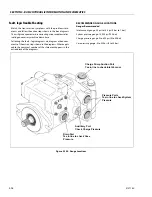

Страница 425: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 3121160 5 81 Figure 5 131 Variable Displacement Pump Rexroth...

Страница 443: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 3121160 5 99 Figure 5 146 Fault Logic Troubleshooting...

Страница 444: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 5 100 3121160 Figure 5 147 Fault Logic Troubleshooting...

Страница 445: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 3121160 5 101 Figure 5 148 Fault Logic Troubleshooting...

Страница 460: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 5 116 3121160 NOTES...

Страница 467: ...SECTION 6 JLG CONTROL SYSTEM 3121160 6 7 Figure 6 2 ADE Block Diagram...

Страница 471: ...SECTION 6 JLG CONTROL SYSTEM 3121160 6 11 Figure 6 6 Analyzer Flow Chart Prior to Version 5 X Software Sheet 4 of 4...

Страница 473: ...SECTION 6 JLG CONTROL SYSTEM 3121160 6 13 Figure 6 8 Analyzer Flow Chart Version 5 X Software Sheet 2 of 4...

Страница 534: ...SECTION 6 JLG CONTROL SYSTEM 6 74 3121160 NOTES...

Страница 545: ...SECTION 7 BASIC ELECTRICAL INFORMATION SCHEMATICS 3121160 7 11 Figure 7 15 Connector Installation...

Страница 580: ...SECTION 7 BASIC ELECTRICAL INFORMATION SCHEMATICS 7 46 3121160 NOTES...

Страница 581: ......