SECTION

4

- BOO

M

& PLATFOR

M

4-68

3121160

Turntable Sensor Faulted

8/1 TURNTABLE FAULTED

If the system detects that the Chassis tilt sensor frequency out-

side the 100Hz +/- 5Hz range or the duty cycle is outside 50% +/-

21% range the control system shall report a fault.

Solution:

• Inspect wire harness going to the sensor and UMS module.

• Inspect sensor mounting.

• Replace sensor.

EEPROM checksums failure

9/9 EEPROM FAILURE – CHECK ALL SETTINGS

A critical failure occurred with the EEPROM. Personalities,

machine configuration digits, etc. may be reset to default values

and should be checked.

Solution:

• Contact JLG if message is reoccurring.

4.19 UMS TROUBLESHOOTING AND FAULT

MESSAGES-ADE MACHINES

Backward Stability Concern Message

2/5 UMS SENSOR BACKWARD LIMIT REACHED

When the upright angle relative to the turntable is higher than

+2.5° (away from the work platform), tower lift down will be dis-

allowed immediately. Tower Lift Down will be re-allowed when

the upright angle relative to the turntable is less than 2.0

. If

Tower Lift Down is disabled for more than 1.5 seconds, the

ground boom malfunction indicator lamp, upright tilted lamp

and platform alarm will light/sound continually and a fault shall

be raised. These conditions will be latched along with Tower Lift

Down until the upright angle is less than 2.0

for 2 seconds and

the Tower Lift Down command is returned to neutral.

Solution:

• Inspect sensor mounting.

• Verify sensor calibration on level pad.

• Follow the corrective action listed on decal 1702265

located near the red knob of the machine.

• Inspect machine hydraulics.

Forward Stability Concern Message

2/5 UMS SENSOR FORWARD LIMIT REACHED

When the upright angle relative to the turntable is less than –4.0°

for longer than 1.5 seconds, the ground control boom malfunc-

tion indicator lamp, the platform malfunction indicator lamp,

and platform alarm will light/sound continually and a fault will

be raised. The light/alarm signal will stop only when the upright

angle reaches values greater than –3.0° for 2 seconds.

Solution:

• Inspect sensor mounting.

• Verify sensor calibration on level pad.

• Tower lift down.

• Inspect machine hydraulics.

Auto Detection Input Low Message

2/5 AUTO DETECTION INPUT LOW

If the UMS detects a valid ground module software version but

digital input 2 is not tied high the UMS module shall report a

fault.

Solution:

• Inspect wire harness, there should be 12 volts going into

pin J1-5 (black connector) of UMS module.

UMS Sensor Communications lost

6/6 UMS SENSOR COMMUNICATIONS LOST

If the UMS detects a valid ground module software version but

digital input 2 is not tied high the UMS module shall report a

fault.

Solution:

• Inspect wire harness; CANbus communications are on pins

J2-9 & J2-10 (gray connector) of the UMS module.

• Using access level 1 of the UMS module, under “DIAGNOS-

TICS” CAN, RX/SEC and TX/SEC should be values greater

than 0. Also “BUS OFF:” and “BUS ERR:” should be 0 and

“PASSIVE:” should be a low value.

Содержание 740AJ

Страница 1: ...Service and Maintenance Manual Model 740AJ Prior to S N 0300185827 P N 3121160 October 24 2017 AS NZS...

Страница 2: ......

Страница 51: ...SECTION 2 GENERAL 3121160 2 11 Figure 2 2 Engine Operating Temperature Specifications Ford 4150548 E...

Страница 55: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 3 This page left blank intentionally...

Страница 56: ...SECTION 3 CHASSIS TURNTABLE 3 4 3121160 1 Figure 3 2 Axle and Steering Installation Sheet 1 of 2 0258286 C...

Страница 100: ...SECTION 3 CHASSIS TURNTABLE 3 48 3121160 Figure 3 37 Swing Bearing Tolerance Boom Placement Sheet 1 of 2...

Страница 101: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 49 Figure 3 38 Swing Bearing Tolerance Boom Placement Sheet 2 of 2...

Страница 116: ...SECTION 3 CHASSIS TURNTABLE 3 64 3121160 Figure 3 44 Swing Hub Prior to SN 0300074383...

Страница 124: ...SECTION 3 CHASSIS TURNTABLE 3 72 3121160 Figure 3 45 Swing Drive Hub Fairfield SN 0300074383 through 0300134352...

Страница 180: ...SECTION 3 CHASSIS TURNTABLE 3 128 3121160 1 Figure 3 66 Auxiliary Pump Location 1 AuxiliaryPump 2 HydraulicTank...

Страница 203: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 151 Figure 3 77 EFI Component Location...

Страница 206: ...SECTION 3 CHASSIS TURNTABLE 3 154 3121160 Figure 3 78 ECM EPM Identification ECM EPM...

Страница 213: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 161 Megajector Regulator LockoffSolenoid Figure 3 80 LPG System Components Mixer...

Страница 219: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 167 Figure 3 81 Check Out and Initial Start Up Procedures...

Страница 224: ...SECTION 3 CHASSIS TURNTABLE 3 172 3121160 Figure 3 83 Deutz EMR 2 Troubleshooting Flow Chart...

Страница 225: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 173 Figure 3 84 Deutz EMR 2 Vehicle Side Connection Diagram...

Страница 226: ...SECTION 3 CHASSIS TURNTABLE 3 174 3121160 Figure 3 85 Deutz EMR 2 Engine Side Connection Diagram Sheet 1 of 2...

Страница 227: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 175 Figure 3 86 Deutz EMR 2 Engine Side Connection Diagram Sheet 2 of 2...

Страница 228: ...SECTION 3 CHASSIS TURNTABLE 3 176 3121160 Figure 3 87 EMR 2 Engine Plug Pin Identification...

Страница 229: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 177 Figure 3 88 EMR 2 Vehicle Plug Pin Identification...

Страница 230: ...SECTION 3 CHASSIS TURNTABLE 3 178 3121160 Figure 3 89 EMR2 Fault Codes Sheet 1 of 5...

Страница 231: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 179 Figure 3 90 EMR2 Fault Codes Sheet 2 of 5...

Страница 232: ...SECTION 3 CHASSIS TURNTABLE 3 180 3121160 Figure 3 91 EMR2 Fault Codes Sheet 3 of 5...

Страница 233: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 181 Figure 3 92 EMR2 Fault Codes Sheet 4 of 5...

Страница 234: ...SECTION 3 CHASSIS TURNTABLE 3 182 3121160 Figure 3 93 EMR2 Fault Codes Sheet 5 of 5...

Страница 303: ...SECTION 4 BOOM PLATFORM 3121160 4 31 Figure 4 20 Rotator Assembly HELAC...

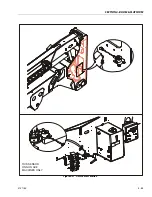

Страница 335: ...SECTION 4 BOOM PLATFORM 3121160 4 63 THIS SENSOR ON NON ADE MACHINES ONLY Figure 4 27 UMS Sensor Location...

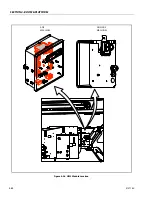

Страница 336: ...SECTION 4 BOOM PLATFORM 4 64 3121160 Figure 4 28 UMS Module Location ADE MACHINES NON ADE MACHINES...

Страница 425: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 3121160 5 81 Figure 5 131 Variable Displacement Pump Rexroth...

Страница 443: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 3121160 5 99 Figure 5 146 Fault Logic Troubleshooting...

Страница 444: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 5 100 3121160 Figure 5 147 Fault Logic Troubleshooting...

Страница 445: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 3121160 5 101 Figure 5 148 Fault Logic Troubleshooting...

Страница 460: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 5 116 3121160 NOTES...

Страница 467: ...SECTION 6 JLG CONTROL SYSTEM 3121160 6 7 Figure 6 2 ADE Block Diagram...

Страница 471: ...SECTION 6 JLG CONTROL SYSTEM 3121160 6 11 Figure 6 6 Analyzer Flow Chart Prior to Version 5 X Software Sheet 4 of 4...

Страница 473: ...SECTION 6 JLG CONTROL SYSTEM 3121160 6 13 Figure 6 8 Analyzer Flow Chart Version 5 X Software Sheet 2 of 4...

Страница 534: ...SECTION 6 JLG CONTROL SYSTEM 6 74 3121160 NOTES...

Страница 545: ...SECTION 7 BASIC ELECTRICAL INFORMATION SCHEMATICS 3121160 7 11 Figure 7 15 Connector Installation...

Страница 580: ...SECTION 7 BASIC ELECTRICAL INFORMATION SCHEMATICS 7 46 3121160 NOTES...

Страница 581: ......