ORBIMAT CA

| Operating instructions

Service and troubleshooting

(09.03.15) OW_ORBIMAT_CA_BA_871060202_04_EN

orbitalum tools

GmbH, D-78224 Singen, www.orbitalum.com, Tel. +49 (0) 77 31 792-0

73

45

Incorrect weld head

connected!

The currently connected weld head is not the same as the weld head in the started

procedure.

X

Select connected weld head in the procedure.

– or –

X

Connect the weld head selected in the procedure to the machine.

Are the weld head models identical, but the message appears anyway?

X

Contact Orbitalum service.

46

The procedure contains

parameters which lie

outside the limit values

for the selected weld

head!

Weld head changed in procedure. Weld head does not match the one in the parameters.

The weld head list of the machine contains the parameters of the weld heads which

can be connected to the machine, e.g. the maximum rotation of the rotor, the maximum

pipe diameter to be welded and the maximum permissible current.

X

Adjust parameters of the program to the selected weld head.

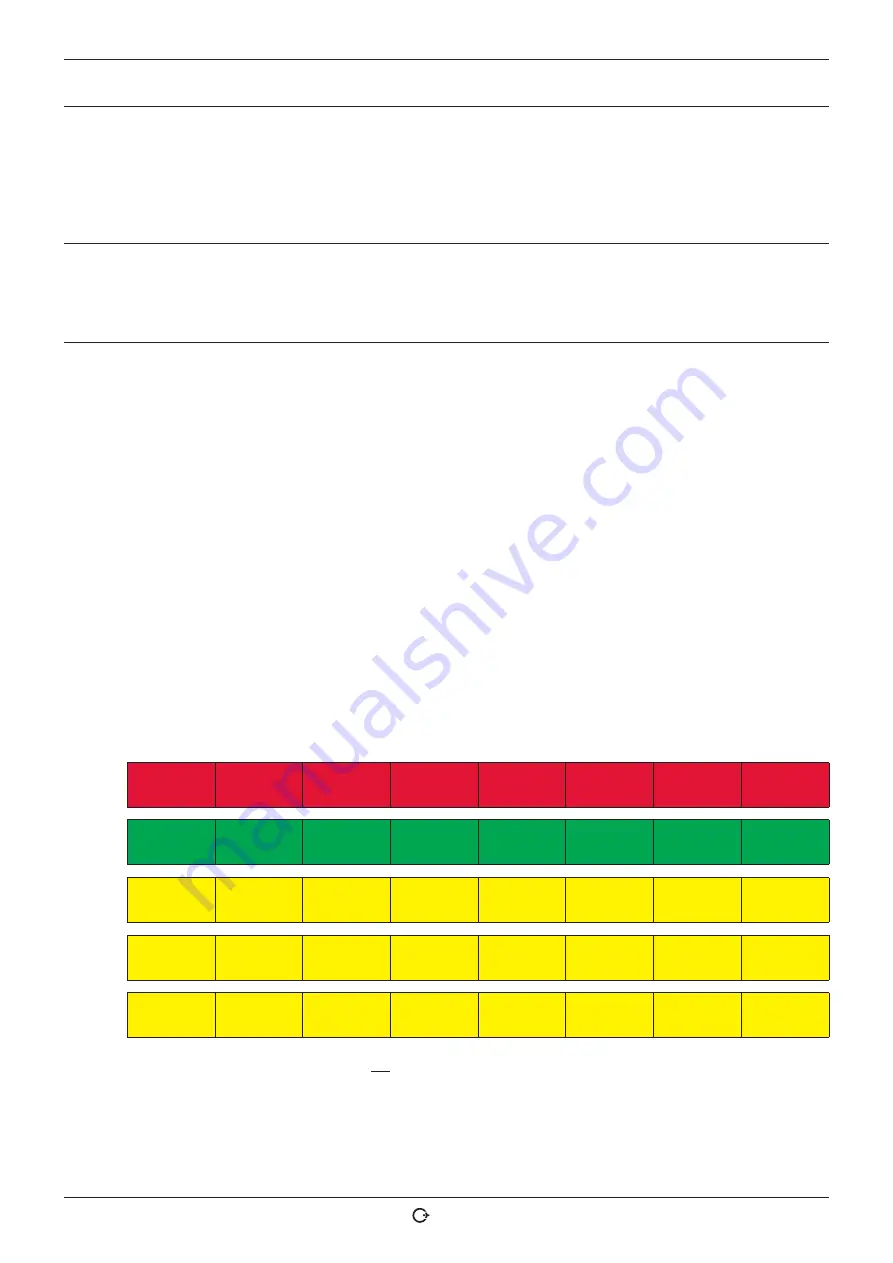

9.4

Status LED indicators

The back of the machine is equipped with five LED rows (A through E) with eight LEDs each.

The status of all important internal signals of the unit is signaled by the LEDs. The LED indicators work independently of

the control computer of the machine.

Row A:

Red LEDs (row A) are lit up: Internal control fuses defective.

Row B:

Green LEDs (row B) are lit up: Internal control voltages for PC, motor, valves etc. are active.

For OM 165 CA and OM 300 CA units: Indicator B2 – printer power supply unit. Indicator lights up if the internal printer

was switched on (by a print command).

Yellow LEDs:

Indicate various functions. Switched on or off depending on the operating condition of the system and the function.

1

2

3

4

5

6

7

8

A

Fuse 1

Weld head

(defective)

Fuse 2

Printer

(defective)

Fuse 3

Motor

(defective)

Fuse 4

Pump, PU1

(defective)

Fuse 5

Computer

(defective)

Fuse 6

Pump, PU2

(defective)

not used

(spare)

not used

(spare)

B

PS – WH

Weld head

(OK)

PS – PR

Printer

(OK)

PS – MOT

Motor

(OK)

not used

(spare)

(jump. to B3)

PS – PC

Computer

(OK)

24 _DI

int. supply

(OK)

PS – INV

int. supply

(OK)

U – sense

(LED A row)

(OK)

C

Keyswitch

ON

(= full menue)

Arc Gas

Sensor

(ON = OK)

Water Flow

Sensor*

(ON = OK)

Water Pump

PS - PU 1

(ON = OK)

Water Pump

enable signal

(ON = enabl.)

Water Pump

PS - PU 2

(ON = OK)

external

Sensor

(ON = OK)

not used

(spare)

D

Fas Valve

enable signal

(ON = enabl.)

Fan 1

(left side)

(ON = OK)

Fan 2

(right side)

(ON = OK)

Start Stop

Key (WH-T)

(ON = enabl.)

Gas Test

Key (WH-E)

(ON = enabl.)

Motor

Key (WH-S)

(ON = enabl.)

Home

Key (WH-D)

(ON = enabl.)

Home

Switch (WH-A)

(ON = enabl.)

E

Motor Releay

enable signal

(ON = enabl.)

Twin Switch

Signal (WH-F)

(ON = Pos.2)

Weld head ID

Bit 0 (WH-L)

(ON = enabl.)

Weld head ID

Bit 1 (WH-M)

(ON = enabl.)

Weld head ID

Bit 2 (WH-N)

(ON = enabl.)

Weld head ID

Bit 3 (WH-U)

(ON = enabl.)

Weld head ID

Bit 4 (WH-W)

(ON = enabl.)

CAJON-MODE

(WH-G)**

(ON = enabl.)

* signals for Water Flow Sensor (C3) not available on OM 165 CB with S/N 102 to 111 - only over service screen.

** LED only ON, when CAJON interface integrated

and

CAJON mode enabled (head with adaptor connected).