Operation

ORBIMAT CA

| Operating instructions

40

orbitalum tools

GmbH, D-78224 Singen, www.orbitalum.com, Tel. +49 (0) 77 31 792-0

(09.03.15) OW_ORBIMAT_CA_BA_871060202_04_EN

Auto programming uses these linear transitions. This reduces the number of sectors. The effects to be compensated for

by a change in current (e.g. heating of the pipes during welding) do not have a sudden character and can be compen-

sated for better using transitions.

Alternatively, it is also possible by adjusting the weld speed. With different weld speeds, however, the seam

appearance changes ("scaling") if the high- and low-pulse times are not adjusted in the same proportion.

Recommendation for standard applications

X

The procedure of a constant weld speed within a program "recommended" by auto programming is retained.

X

To achieve an even seam with proper weld penetration, adjust the current setting in the individual sectors.

For minor adjustments:

X

Change only the high-pulse current.

– or –

X

Change both currents in the same direction to obtain the desired "pulse effect".

1. In the main menu, select "

Manual/Adjust programming

" > "

Adjust parameters

".

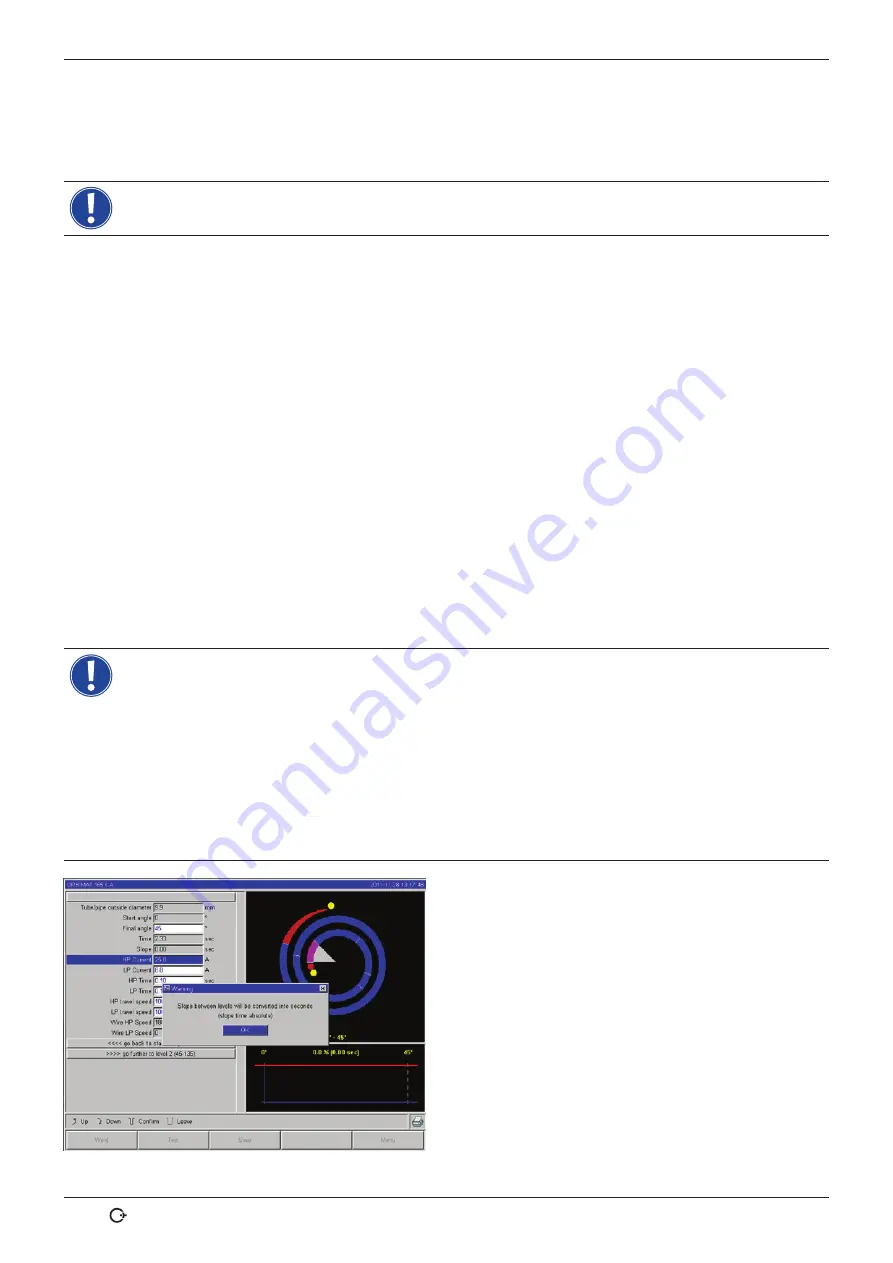

2. Select desired sector.

The respective selected sector is highlighted in color to the right in the display. The angular degree of this sector is specified.

3. Select, highlight, adjust and save the "

HP current

", "

LP current

" and "

Slope

" parameters.

4. Press softkey 1 ("

Weld

") or softkey 2 ("

Test

").

The machine is ready to start.

The specification of the current transition in percent is then problematic under certain circumstances if

programs from other machines must be transferred with an incompatible data format and these machines

are programmed with a slope in seconds instead of percent.

The field for input of the slope time can be switched from percent to seconds, see also "Special keyboard

commands" (chap. 8.17, p. 62).

X

To switch the slope time specification from % to sec (and vice versa), press the "S", "L" and "O" keys

(for SLOPE) on the external keyboard.

X

Confirm message (see Fig. 20) by pressing the rotary knob.

The next time the machine is started, the % values corresponding to the seconds appear.

Fig. 19:

Converting the slope time from percent to seconds