ORBIMAT CA

| Operating instructions

Operation

(09.03.15) OW_ORBIMAT_CA_BA_871060202_04_EN

orbitalum tools

GmbH, D-78224 Singen, www.orbitalum.com, Tel. +49 (0) 77 31 792-0

49

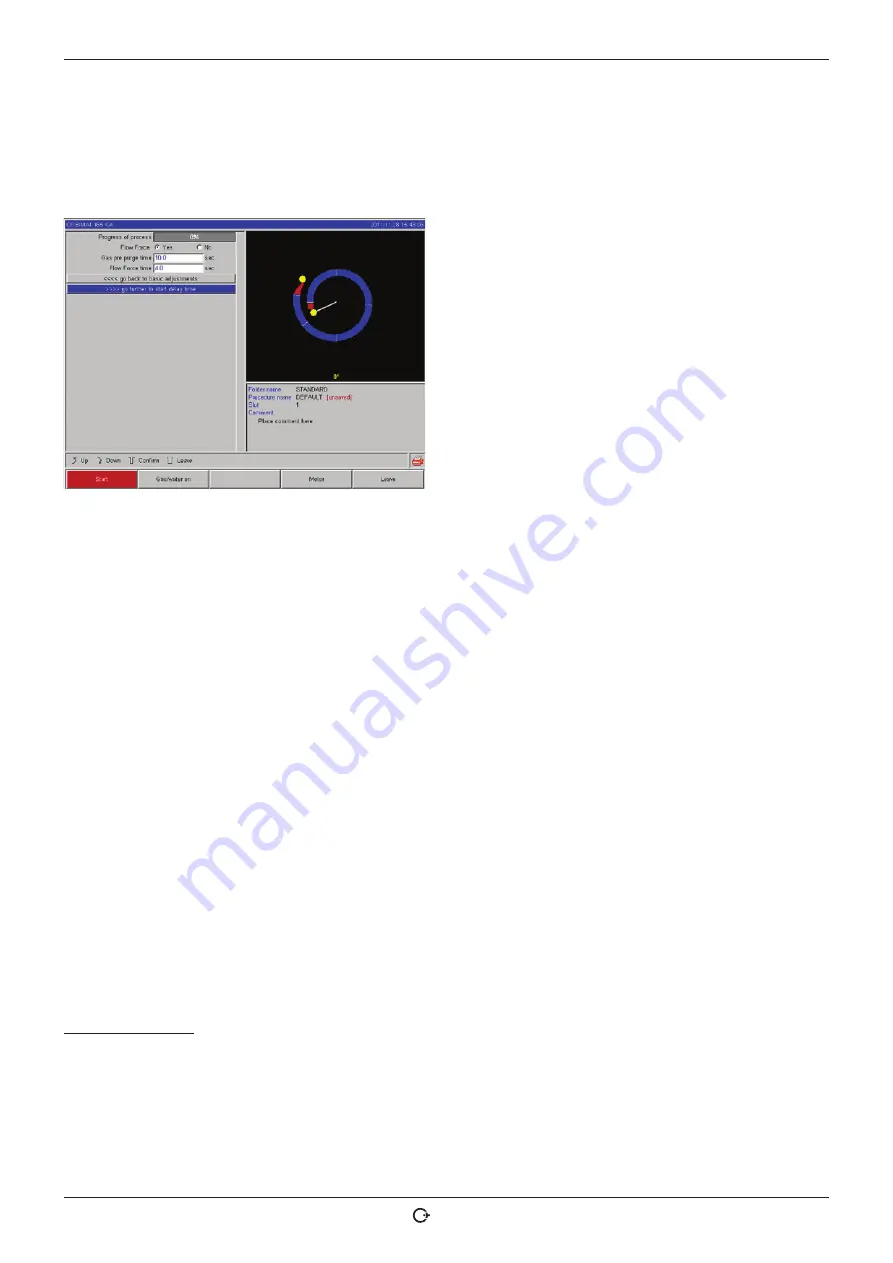

Activating a gas pressure level

1. Switch to "

Weld

" mode with "

go forward to gas pre purge time

" to set the gas pre purge time.

The following display appears:

2. Select the "

Yes

" option for "

Flow Force

".

The "

Flow Force time

" field is activated.

3. Enter and save value for the flow force.

Fig. 24:

Flow Force

8.8

Connecting supplementary devic

8.8.1

ORB Residual Oxygen Meter

The residual oxygen meter can be used separately or connected to the machine.

Separate use:

If the limit value set at the meter is undershot by the device, a warning signal is sounded. This has no effect on the

welding process. The operator can carry out other measures.

Connection to the machine:

The machine cannot be started as long as the residual oxygen value lies above the set limit value. If the limit value is

exceeded, the process is canceled and a note is entered in the log.

8.8.2

Connecting and configuring the BUP control unit

The BUP control unit enables a defined and programmable internal pipe pressure (forming gas) to be built up in con-

junction with suitable plugs for closing off the pipe on both sides. This pressure is controlled based on the electrode

position. Thus an incursion of the weld seam which occurs in the flat position can be reduced or eliminated.

The control unit does not have its own power supply: It is connected to the machine via the connection socket and is

thus ready for operation.

Connecting the unit

1. Connect unit to the "BUP Control" connection socket of the machine.

2. In the main menu, select "

System settings

" > "

System adjustments

".

3. Select the "

Yes

" option for "

External input for abort

".

The signal from the oxygen meter is monitored continuously.