7PG2113/4/5/6 Solkor Description of Operation

4.1.3 Time Delayed Overcurrent Protection (51)

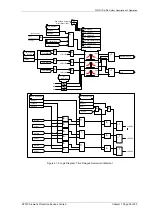

Two time delayed overcurrent elements are provided in the 7PG2113/5 relay and four elements are provided in

the 7PG2114/6 relay.

51-1, 51-2, (51-3 & 51-4 –7PG2114/6)

51-n Setting

sets the pick-up current level. Where the voltage controlled overcurrent function (51VCO) is used a

multiplier is applied to this setting where the voltage drops below the setting

VCO Setting

, see Section 3.2.

A number of shaped characteristics are provided. An inverse definite minimum time (IDMT) characteristic is

selected from IEC, ANSI or manufacturer specific curves using

51-n Char

. A time multiplier is applied to the

characteristic curves using the

51-n Time Mult

setting. Alternatively, a definite time lag delay (DTL) can be

chosen using

51-n Char

. When Definite Time Lag (DTL) is selected the time multiplier is not applied and the

51-n

Delay (DTL)

setting is used instead. The full list of operating curves is given in Section 2 – ‘Settings and

Instruments Guide’. Operating curve characteristics are illustrated in Section 3 – ‘Performance Specification’.

The

51-n Reset

setting can apply a

definite time delayed

reset

,

or when configured as an ANSI characteristic an

ANSI (DECAYING)

reset. If ANSI (DECAYING) reset is selected for an IEC characteristic, the reset will be

instantaneous. The reset mode is significant where the characteristic has reset before issuing a trip output – see

‘Applications Guide’.

A minimum operate time for the characteristic can be set using

51-n Min. Operate Time

setting.

A fixed additional operate time can be added to the characteristic using

51-n Follower DTL

setting.

Where directional elements are present the direction of operation can be set using

51-n Dir. Control

setting.

Directional logic is provided independently for each 51-n element

Operation of the time delayed overcurrent elements can be inhibited from e.g. giving the option of using two

elements set to forward and two to reverse.

Inhibit 51-n

A binary or virtual input.

79 P/F Inst Trips: 51-n

When ‘delayed’ trips only are allowed in the auto-reclose sequence

(

79 P/F Prot’n Trip n

=

Delayed

).

51c

Activation

of

the cold load settings.

51-n Inrush Action: Block

Operation of the inrush current detector function.

51-n VTSAction: Inhibit

Operation of the VT Supervision function (7PG2114/6).

©2010 Siemens Protection Devices Limited Chapter 1 Page 38 of 80