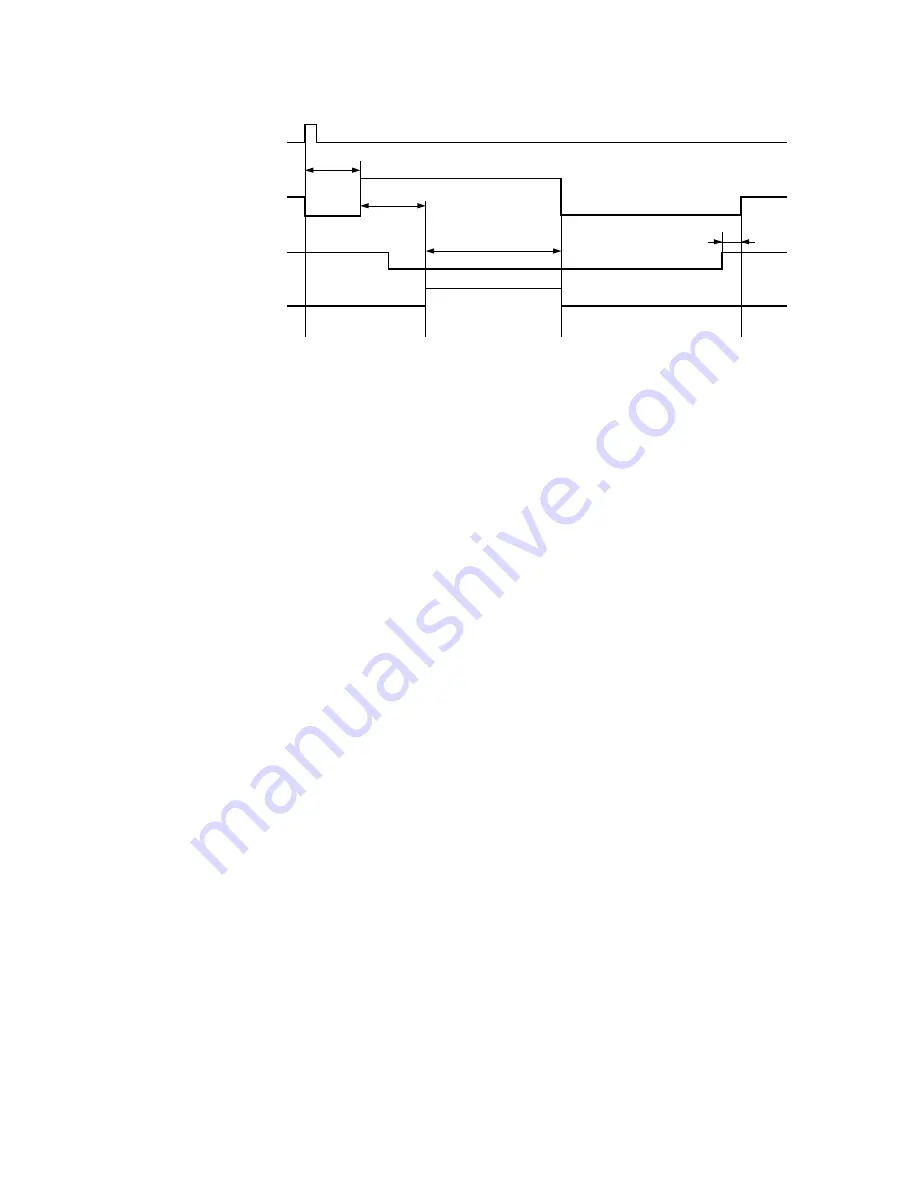

2AR

1-3-15

Start key

SM

Fwd. rotation

Rev. rotation

SHPSW

FVSYNC signal

A

B

270 P

414 P

9921 P

120 P

C

D

Original: A3/11" ¥ 17", magnification ratio 100%

Timing chart 1-3-3 Scanner operation

A

When the start key is pressed, the scanner motor (SM) reverses for 270 pulses and

then rotates forward.

B

414 pulses after the scanner motor (SM) starts rotating forward, the FVSYNC signal

turns on for 9921 pulses for scanning.

C

The scanner motor (SM) reverses to return the scanner to the home position.

D

120 pulses after the scanner home position switch (SHPSW) turns on, the scanner

motor (SM) turns off, and the scanner stops at its home position.

Summary of Contents for PointSource Ai 3010

Page 1: ...3010 S M MCA SERVICE MANUAL Published in Apr 00 2AR70765 Revision 5 PointSource Ai 3010 R...

Page 2: ...Service Manual PointSource Ai 3010...

Page 13: ...3010 S M MCA THEORY AND CONSTRUCTION SECTION I I Theory and Construction Section...

Page 14: ...2AR CONTENTS 1 1 Specifications 1 1 1 Specifications 1 1 1...

Page 18: ...2AR CONTENTS 1 2 Handling Precautions 1 2 1 Drum 1 2 1 1 2 2 Developer and toner 1 2 1...

Page 61: ...3010 S M MCA ELECTRICAL SECTION II II Electrical Section...

Page 62: ...2AR CONTENTS 2 1 Electrical Parts Layout 2 1 1 Electrical parts layout 2 1 1 1 Copier 2 1 1...

Page 92: ...3010 S M MCA III Set Up and Adjustment Section III SET UP AND ADJUSTMENT SECTION...

Page 108: ...3 1 15 2AR This page has been left blank intentionally 2AR 5...

Page 136: ...3 2 11 2AR 1 This page is intentionally left blank...

Page 191: ...3 2 62 2AR 1 This page is intentionally left blank...

Page 196: ...3 2 61 2AR 1 This page is intentionally left blank...

Page 255: ...3 2 38 2AR 1 This page is intentionally left blank...

Page 384: ...2AR 1 3 6 15 This page is intentionally left blank...

Page 398: ...3 6 27 2AR 1 3 Main PCB CN9 CN5 CN2 CN3 CN4 IC11 IC12 CN1 CN8 CN10 CN11 CN6 CN7...

Page 431: ...2AR General connection diagram 3 7 43 General wiring diagram 3 7 44 2AR 1...