Fuel System 95 General Information

3. Repair Method of Connector Terminal

a. Clean the contact points using air gun and/or

shop rag.

✍

NOTICE

Never use sand paper when polishing the

contact points, otherwise the contact point may

be damaged.

b. In case of abnormal contact pressure, replace the

female terminal.

Wire Harness Inspection Procedure

.

1. Before removing the wire harness, check the wire

harness position and crimping in order to restore it

correctly.

2. Check whether the wire harness is twisted, pulled or

loosened.

3. Check whether the temperature of the wire harness

is abnormally high.

4. Check whether the wire harness is rotating, moving

or vibrating against the sharp edge of a part.

5. Check the connection between the wire harness and

any installed part.

6. If the covering of wire harness is damaged; secure,

repair or replace the harness

Electrical Circuit Inspection Procedure

1. Procedures for Open Circuit

• Continuity Check

• Voltage Check

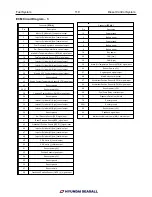

If an open circuit occurs (as seen in [FIG. 1]), it can

be found by performing Step 2 (Continuity Check

Method) or Step 3 (Voltage Check Method) as shown

Below

2. Continuity Check Method

✍

NOTICE

When measuring for resistance, lightly shake the

wire harness above and below or from side to side.

--------------------------------------------------------------------

Specification (Resistance)

1Ω or less →

Normal Circuit

1

㏁

or Higher

→

Open Circuit

--------------------------------------------------------------------

a. Disconnect connectors (A), (C) and measure

resistance between connector (A) and (C) as

shown in [FIG. 2].

In [FIG.2.] the measured resistance of line 1 and

2 is higher than 1

㏁

and

below 1 Ω respectively.

Specifically the open circuit is line 1 (Line 2 is

normal). To find exact break point, check sub line

of line 1 as described in next step.

Summary of Contents for S220P

Page 3: ...Engine Mechanical System 2 General Information General Information Specifications ...

Page 4: ...Engine Mechanical System 3 General Information Specifications ...

Page 5: ...Engine Mechanical System 4 General Information Specifications ...

Page 10: ...Engine Mechanical System 9 Cooling System Special Service Tools ...

Page 11: ...Engine Mechanical System 10 Cooling System Special Service Tools ...

Page 18: ...Engine Mechanical System 17 Cooling System ...

Page 19: ...Engine Mechanical System 18 Cooling System Thermostat ...

Page 55: ...Engine Mechanical System 54 Lubrication System ...

Page 73: ...Engine Electrical System 72 General Information Troubleshooting Charging system ...

Page 74: ...Engine Electrical System 73 General Information Starting system Special service tools ...

Page 75: ...Engine Electrical System 74 Charging System Charging system Alternator ...

Page 80: ...Engine Electrical System 79 Starting System Components ...

Page 91: ...Fuel System 90 General Information Special Service Tools ...

Page 112: ...Fuel System 111 Diesel Control System EOI Engine Operating Indicator System Circuit Diagram 1 ...

Page 117: ...Fuel System 116 Diesel Control System Specification Circuit Diagram ...