6-2

Chapter 6

Inspection and maintenance

6.2 Daily and periodic inspections

*1) The life span of the smoothing capacitor is influenced by the

ambient temperature. Refer to [Smoothing capacitor life span

curve] for replacing measures.

*2) The life span of the cooling-fan is influenced by the ambient

temperature, the dirt and the change in its environmental

conditions. Check these circumstances on the usual inspection.

*3) The estimated time before replacement (Number of years/cycle) and

the [Smoothing capacitor life span curve] are based on the design

lifespan, not guaranteed.

*4) In the case that the capacitors are replaced after that the storage

period of 3 years has expired, before the first use please refer to the

aging process under the following conditions before using them:

・

First, apply for 1 hour the 80% of the capacitor rated voltage at

ambient temperature

・

Then, raise the voltage to 90%, and keep it for 1 more hour.

・

Finally, apply for 5 hours the rated voltage at ambient temperature

*5) In the case that the cooling-fan if affected by dust, obstructing it;

remove the dust, after that may take 5 to 10 seconds to start again.

*6) Follow the installed motor instructions

Inspected

part

Inspection

entry

Details of inspection

Inspection cycle

Inspection method

Criterion

Tester device

Daily

Every

1

year

2

years

General

Surrounding

environment

Check the ambient temperature,

level of humidity, dust, … etc.

○

Refer to the installation guide.

Ambient temperature, level of

humidity are withing the range.

No frozen part. No condensation.

Thermometer

Hygrometer

Data logger

Whole inverter Check abnormal vibrations or noises

○

Check visually and auditorily. Without abnormalities

Power supply

voltage

Check that the main circuit voltage

is normal.

○

Measure the line-to-line

voltage of the inverter main

circuit terminals R,S and T.

Within the AC voltage

permissible variation.

Multimeter,

Digital multimeter

Meter

Main

circuit

General check

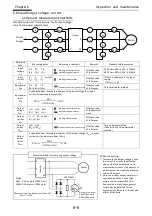

(1)Check the resistance between the

main circuit and the ground terminals.

○

Dismantle the inverter main

circuit terminals input/output

wiring and the control terminal

board, and remove the jumper

for the internal filter, after

that, shortcircuit the terminals

R,S,T,U,V,W,P,PD,N,RB,R0,T0,

and measure between this

shortcircuit and the ground.

Resistance no less than 5MΩ.

DC 500V class

Ohmmeter

(megger®)

(2)Check looseness in fastened parts

○

Confirm tighten of fasteners.

Without abnormalities

(3)Check for overheating traces.

○

Check visually.

Without abnormalities

Conductor and

cables

(1)Check for straining in conductors

○

Check visually.

Without abnormalities

(2)Check for cable coating damage

○

Terminal block Check for any damage.

○

Check visually.

Without abnormalities

Inverter and

converter

circuits

(Including

resistors)

Check the resistance between all the

terminals

○

Remove the inverter main

circuit terminal wiring, and

measure the following:

- Resistance between

terminals RST and PN.

- Resistance between

terminals UVW and PN

Consult the “Method of

checking the inverter and

converter circuits”. The inverter,

capacitor and thyristor lifespan

before replacing the

componentes is of 10

6

start/stop cycles *3)

Analogue

multimeter

Smoothing

capacitor

(1)Check for capacitor fluid leakage

○

Check visually.

That there are no abnormalities

Estimated number life span

before exchanging component:

10 years

*1) *3) *4)

Capacitance

meter

(2)Check that the relief valve does not

swells or protudes.

○

Relay

(1)No chatter sound while operating

○

Check auditorily.

That there are no abnormalities.

(2)Check contacts for damage

○

Check visually.

That there are no abnormalities.

Control and

protection

circuits

Operation

check

(1) While performing a unit operation

of the inverter, check the balance of

the output voltage among the

individual phases

○

Measure the voltage between

the U,V,W terminals of the

inverter main circuit.

Phase-to-phase voltage balance

200V class: within 4V

400V class: within 8V

Digital multimeter

Voltmeter

Ammeter

(2)Carry out a sequential protection

test, and check the protective and

display circuits for any abnormality

○

Simulate a shortcircuit or open

of the inverter output

protection circuit.

An error must be detected

according to the sequence.

Cooling

system

Cooling-fan

(1) Check for abnormal vibrations or

noises

○

Turn by hand while electricity

is not being supplied

Smooth operation without

abnomalities.

Replace every: 10 years

*2) *3) *5)

(2)Check for loose joints

○

Check visually.

Heat sink

Check for obstructions/clogging.

○

Check visually.

That there are not obstructions.

Display

Display

(1)Check that LED lamps lights up

○

Check visually.

Confirm it lights up

(2)Display cleaning

○

With cleaning rag.

Meter

Check that Indicated values are

normal.

○

Check the meter readings on

the panel.

Regulation and control value

are satisfactory.

Voltmeter

Ammeter

Etc.

Motor

General

(1)Check abnormal vibrations or noises

○

Check visually,auditorily, and

by touch

Without abnormalities

(2)Check that there is no stench.

○

Check for abnormal

superheating, damages an so

on.

Without abnormalities

Insulation

resistance

Check the resistance between the

main circuit and the ground

terminals.

*6)

Detach the U,V,W terminals

from the inverter main circuit,

and shortcircuit the motor

wiring, mesure with the

Megger® between the motor

wiring and ground terminal.

No less than 5MΩ.

DC 500V class

Ohmmeter

(megger®)

Summary of Contents for P1-00041HFEF

Page 6: ...0 5 Contents Contents Memo ...

Page 42: ...2 26 Chapter 2 Installation and Wiring Memo ...

Page 129: ...Index Index 3 memo ...

Page 130: ...Index Index 4 memo ...