Chapter 6

6.1 I

Check

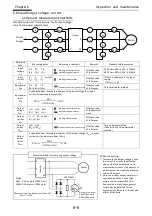

the inverter is operating:

While operating

multimeter

The contents related to the functional safety are listed in

the attachment [Functional safety guide].

Chapter 6

Chapter 6

Inspection

maintenance

Read this before

inspection

There is risk of electric shock!

・

Before

cut off

before proceeding

(Make sure that the

off. Furthermore,

the P and

voltage

6.1 Inspection

6.1.1 Daily

Check and confirm

the inverter is operating:

No.

Details

1

Motor operates as per settings

2

No abnormalities in the environment

3

Cooling

4

Abnormal

5

Discolouration

6

Unusual odour

While operating

multimeter or a similar tool to confirm:

No.

Details

1

Voltage

2

Line-

6.1.2 Regarding

The contents related to the functional safety are listed in

the attachment [Functional safety guide].

Chapter 6

Chapter 6

nspection

maintenance

Read this before

inspection or maintenance

risk of electric shock!

Before an inspection

cut off, and then wait at least 10 minutes

before proceeding.

Make sure that the charge

urthermore, measure

and N terminals

voltage it is less than 45V

nspection and maintenance

Daily inspection

and confirm for the following

the inverter is operating:

Details

Motor operates as per settings

No abnormalities in the environment

Cooling-system running normally

Abnormal vibration

Discolouration and

Unusual odour

While operating, check the inverter input voltage u

or a similar tool to confirm:

Details

oltage supply fluctuation

-to-line voltage balance

Regarding the functional safety

The contents related to the functional safety are listed in

the attachment [Functional safety guide].

nspection and

maintenance

Read this before performing

or maintenance

risk of electric shock!

an inspection the supply power

wait at least 10 minutes

charge lamp in the inverter

measure the voltage between

N terminals and make sure that

is less than 45V)

and maintenance

inspection

following abnormalities

Motor operates as per settings

No abnormalities in the environment

running normally

vibration or noise

and superheating

, check the inverter input voltage u

or a similar tool to confirm:

fluctuation

line voltage balance

functional safety

The contents related to the functional safety are listed in

the attachment [Functional safety guide].

performing any

or maintenance!

the supply power must to be

wait at least 10 minutes or more

in the inverter

the voltage between

and make sure that the

and maintenance notes

abnormalities while

No abnormalities in the environment

running normally

superheating

, check the inverter input voltage using a

functional safety

The contents related to the functional safety are listed in

the attachment [Functional safety guide].

6-1

to be

more

in the inverter is

the voltage between

the

while

✓

□

□

□

□

□

□

sing a

✓

□

□

The contents related to the functional safety are listed in

・

Other than the designated person, do not perform

maintenance, inspection or component replacement.

(Before starting to operate, remove any

metal

isolated tools

6.1.3

Keep

No.

1

2

3

6.1.4

Check the

is stopped

to be carried out

contact

No.

1

2

3

4

5

I

Other than the designated person, do not perform

maintenance, inspection or component replacement.

Before starting to operate, remove any

metal accessories such as bracelets, and

isolated tools)

6.1.3 Cleaning

Keep the inverter in a clean condition.

No.

Details

1

When cleaning

cloth soaked in neutral detergent

wipe up the dirtied part

2

Do not use

toluene or alcohol to clean the inverter, as

it can melt its surface or peel off the

coating.

3

For the display

detergent or alcohol to clean it

6.1.4 Periodic

Check the parts that are

is stopped. The periodic inspection is a vital point that has

to be carried out, f

contact your Hitachi distributor

No.

Details

1

Check for abnormalities in cooling system

・

Heat sink cleaning, etc.

2

Check the f

・

By the

expansion,

may become loose

after confirm

3

Check that there is no damage

corrosion

4

Measurement of the

voltage of insulators

5

Check and replacement of

smoothing capacitator and relay.

Inspection

Other than the designated person, do not perform

maintenance, inspection or component replacement.

Before starting to operate, remove any

accessories such as bracelets, and

Cleaning

the inverter in a clean condition.

cleaning the inverter

cloth soaked in neutral detergent

wipe up the dirtied part

Do not use solvents like acetone, benzene,

toluene or alcohol to clean the inverter, as

it can melt its surface or peel off the

display of the panel

detergent or alcohol to clean it

Periodic inspection

that are only accessible

he periodic inspection is a vital point that has

, for any periodic inspection, please

your Hitachi distributor

Check for abnormalities in cooling system

Heat sink cleaning, etc.

Check the fastening and tighten

By the effects of oscillations, thermal

expansion, etc..., the screws and bolts

may become loose, proceed

after confirming.

Check that there is no damage

corrosion to the conductor

Measurement of the dielectric breakdown

voltage of insulators

Check and replacement of

smoothing capacitator and relay.

nspection and maintenance

Other than the designated person, do not perform

maintenance, inspection or component replacement.

Before starting to operate, remove any wrist

accessories such as bracelets, and use always

the inverter in a clean condition.

the inverter, use a soft

cloth soaked in neutral detergent to

wipe up the dirtied parts.

like acetone, benzene,

toluene or alcohol to clean the inverter, as

it can melt its surface or peel off the

of the panel do not use

detergent or alcohol to clean it.

inspection

only accessible while the inverter

he periodic inspection is a vital point that has

periodic inspection, please

your Hitachi distributor.

Check for abnormalities in cooling system

Heat sink cleaning, etc.

astening and tighten

of oscillations, thermal

the screws and bolts

, proceed to tighten

Check that there is no damage or

to the conductors and insulat

dielectric breakdown

Check and replacement of cooling-fan,

smoothing capacitator and relay.

and maintenance

Other than the designated person, do not perform any

maintenance, inspection or component replacement.

wristwatch or

use always

✓

, use a soft

to gently

□

like acetone, benzene,

toluene or alcohol to clean the inverter, as

it can melt its surface or peel off the

□

do not use

□

while the inverter

he periodic inspection is a vital point that has

periodic inspection, please

✓

Check for abnormalities in cooling system

□

of oscillations, thermal

the screws and bolts

to tighten

□

insulators

□

dielectric breakdown □

fan,

□

and maintenance

any

while the inverter

he periodic inspection is a vital point that has

Summary of Contents for P1-00041HFEF

Page 6: ...0 5 Contents Contents Memo ...

Page 42: ...2 26 Chapter 2 Installation and Wiring Memo ...

Page 129: ...Index Index 3 memo ...

Page 130: ...Index Index 4 memo ...