EM11 User’s Manual

7. Fault Diagnosis and Solution

131

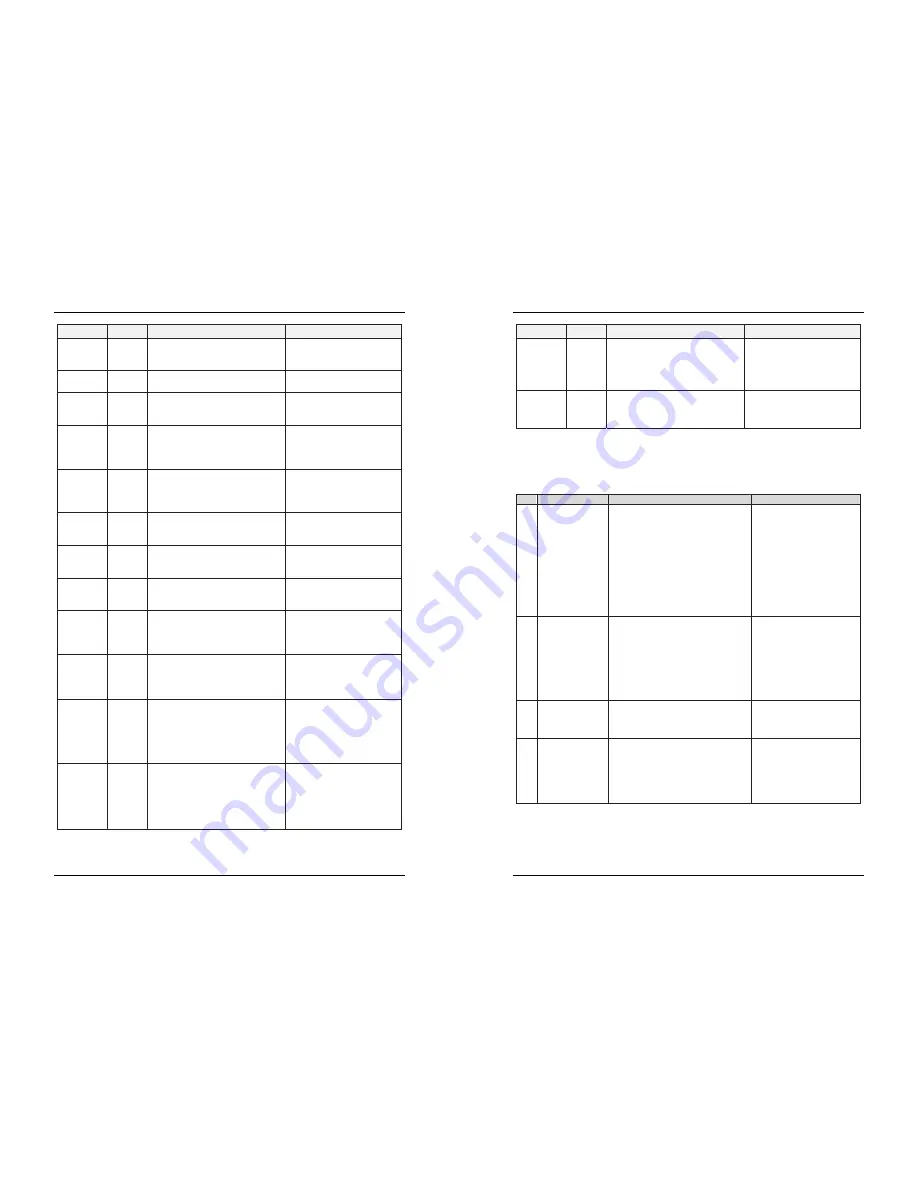

Fault Name

Display

Possible Causes

Solutions

Frequency

inverter

hardware fault

Err22

1: Overvoltage exists.

2: Over current exists.

1: Handle based on over voltage.

2: Handle based on over current.

Short circuit

to ground

Err23

The motor is short circuited to the

ground.

Replace the cable or motor.

Accumulative

running time

reached

Err26

The accumulative running time reaches

the setting value.

Clear the record through parameter

A0-09

User-defined

fault 1

Err27

1: The signal of user-defined fault 1 is

input via DI.

2:The signal of user-defined fault 1 is

input via virtual I/O.

1: Reset the operation.

2: Reset the operation.

User-defined

fault 2

Err28

1: The signal of user-defined fault 2 is

input via DI.

2:The signal of user-defined fault 2 is

input via virtual I/O.

1: Reset the operation.

2: Reset the operation.

Accumulative

power-on time

reached

Err29

The accumulative power-on time reaches

the setting value.

Clear the record through parameter

A0-09

Off load

Err30

The frequency inverter running current is

lower than the setting value.

Check that the load is

disconnected or the parameter

setting is correct.

PID feedback

lost during

running

Err31

The PID feedback is lower than the

setting of C0-26.

Check the PID feedback signal or

set C0-26 to a proper value.

By wave

current

limiting fault

Err40

1: The load is too heavy or locked- rotor

occurs on the motor.

2: The frequency inverter model is of too

small power class.

1: Reduce the load and check the

motor and mechanical condition.

2: Select a frequency inverter of

higher power class.

Motor

switchover

fault during

running

Err41

Change the selection of the motor via

terminal during running of the frequency

inverter.

Perform motor switchover after

the frequency inverter stops.

Too large

speed

deviation

Err42

1: The encoder parameters are set

incorrectly.

2: The motor auto-tuning is not

performed.

3: The detection parameters of too large

speed deviation are set incorrectly.

1: Set the encoder parameters

properly.

2: Perform the motor auto-tuning.

3: Set the detection parameters

correctly based on the actual

situation.

Motor

over-speed

Err43

1: The encoder parameters are set

incorrectly.

2: The motor auto-tuning is not

performed.

3: The over-speed detection parameters

are set incorrectly.

1: Set the encoder parameters

properly.

2: Perform the motor auto-tuning.

3: Set the over-speed detection

parameters correctly based on the

actual situation.

7. Fault Diagnosis and Solution

EM11 User’s Manual

132

Fault Name

Display

Possible Causes

Solutions

Motor

overheat

Err45

1: The cabling of the temperature sensor

becomes loose.

2: The motor temperature is too high.

1: Check the temperature sensor

cabling and eliminate the cabling

fault.

2: Lower the carrier frequency or

adopt other heat radiation

measures

Initial position

fault

Err51

1: The motor parameters are not too

deviation based on the actual situation.

1: Check that the motor parameters

are set correctly and whether the

setting of rated current is too

small.

7.2 Common Faults and Solutions

You may come across the following faults during the use of the frequency inverter. Refer to the following

table for simple fault analysis.

Table 8-2 Troubleshooting to common faults of the frequency inverter

SN

Fault

Possible Causes

Solutions

1

There is no display at

power-on.

1: There is no power supply to the

frequency inverter or the power input to the

frequency inverter is too low.

2: The power supply of the switch on the

drive board of the frequency inverter is

faulty.

3: The rectifier bridge is damaged.

4: The control board or the operation panel

is faulty.

5: The cable connecting the control board

and the drive board and the operation panel

loose or breaks.

1: Check the power supply.

2: Check the DC bus voltage.

3:Check the internal wiring plug

4: Change a keypad

5: Ask for technical support.

2

“-coc-” is displayed

at power-on.

1: The cable between the drive board and

the control board is in poor contact.

2: Related components on the control board

are damaged.

3: The motor or the motor cable is short

circuited to the ground.

4: The HALL device is faulty.

5: The power input to the frequency

inverter is too low.

1: Checking wiring

2: Ask for technical support.

3

“Err23” is displayed

at power-on.

1: The motor or the motor output cable is

short-circuited to the ground.

2: The frequency inverter is damaged.

1: Measure the insulation of the

motor and the output cable with

a megger.

2: Ask for technical support.

4

The frequency

inverter display is

normal after

power-on. But

“coc-” is displayed

after running and

stops immediately.

1: The cooling fan is damaged or

locked-rotor occurs.

2: The external control terminal cable is

short circuited.

1: Replace the damaged fan.

2: Eliminate external fault.