6

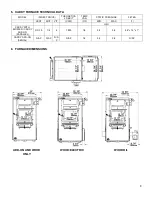

2. APPLIANCE PERFORMANCE

(1)

Fuel type

Dry cordwood

Recommended heating area[*]

1,000 to 2,500 ft² (92.90 à 232.25 m²)

Firebox volume

3.6 ft³ (0.102 m³)

Maximum burn time[*]

15 h

Maximum input capacity (dry cordwood)

(2)

310,000 BTU

Overall heat output rate (min. to max.)

(3)

15,436 BTU/h to 49,638 BTU/h (4.5 kW to 14.5 kW)

Nominal heat output at 15lb/ft³ fuel loading density

75,000 BTU/h

Average overall efficiency

(4)

76.7% (HHV)

(5)

82.9% (LHV)

(6)

Delivered heat output rate (min. to max.)

(7)

12,635 BTU/h to 44,857 BTU/h (3.7 kW to 13.1 kW)

Average delivered efficiency

(8)

62.7% (HHV)

(5)

68.3% (LHV)

(6)

Optimum efficiency

(9)

84.9%

Average particulate emissions rate

(10)(11)

0.654 lb/mmBTU (0.282 g/MJ)

Average CO

(12)

11.18 lb/mmBTU (4.81 g/MJ)

Average electrical power consumption

(13)

432 W

[*]

Recommended heating area and maximum burn time may vary subject to location in home, chimney draft, heat loss factors,

climate, fuel type and other variables. The recommended heating area for a given appliance is defined by the manufacturer as its

capacity to maintain a minimum acceptable temperature considering that the space configuration and the presence of heat

distribution systems have a significant impact in making heat circulation optimum.

(1)

Values are as measured per CSA B415.1-10, except for the recommended heating area, firebox volume, maximum burn time

and maximum input capacity. Performances based on a fuel load prescribed by the standard at 10 lb/ft³ and with moisture

content between 18% and 28%.

(2)

Input value at 10lb/ft³ fuel loading density and dry energy value of 8,600BTU/lb.

(3)

Overall: Radiated and delivered heat together at10lb/ft³ fuel loading density over one total burn cycle.

(4)

Efficiency based on delivered heat when allowing cycling from high to low burn to simulate thermostat demand.

(5)

Higher Heating Value of the fuel.

(6)

Lower Heating Value of the fuel.

(7)

Delivered: Remotely provided to other rooms through ducting at 10 lb/ft³ fuel loading density over one total burn cycle.

(8)

Efficiency based on radiated and delivered heat when allowing cycling from high to low burn to simulate thermostat demand.

(9)

Optimum overall efficiency at a specific burn rate (LHV).

(10)

Based on delivered heat output.

(11)

This appliance is officially tested and certified by an independent agency.

(12)

Carbon Monoxide. Based on overall heat output at 10lb/ft³ fuel loading density.

(13)

Unless st

ated otherwise, measures were taken directly at the main power source and include all electrical components present in

the appliance.

Summary of Contents for PF01015

Page 10: ...10 ADD ON WOOD ONLY WOOD ELECTRIC WOOD OIL ...

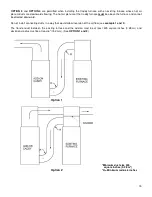

Page 13: ...13 INSTALLATION AND OPERATION INSTRUCTIONS CADDY ADD ON SERIAL INSTALLATION PF01015 ...

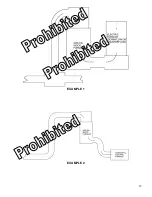

Page 16: ...16 Option 3 Option 4 ...

Page 17: ...17 EXAMPLE 1 EXAMPLE 2 ...

Page 63: ...63 20 GENERAL ELECTRICAL DIAGRAM STANDALONE FURNACE ...

Page 64: ...64 21 ELECTRICAL DIAGRAM FOR PARALLEL FURNACE ...

Page 65: ...65 22 ELECTRICAL DIAGRAM FOR ELECTRIC UNIT ...

Page 78: ...78 31 ELECTRICAL DIAGRAM BECKETT OIL UNIT ...

Page 79: ...79 32 ELECTRICAL DIAGRAM RIELLO OIL UNIT ...

Page 81: ...81 33 4 AIR CONDITIONNING DAMPER 33 5 HUMIDIFIER 33 6 HEAT PUMP ...

Page 82: ...82 34 EXPLODED VIEW AND PART LIST ...

Page 83: ...83 ...

Page 84: ...84 ...

Page 85: ...85 ...

Page 86: ...86 ...

Page 87: ...87 ...

Page 88: ...88 ...

Page 89: ...89 ...