61

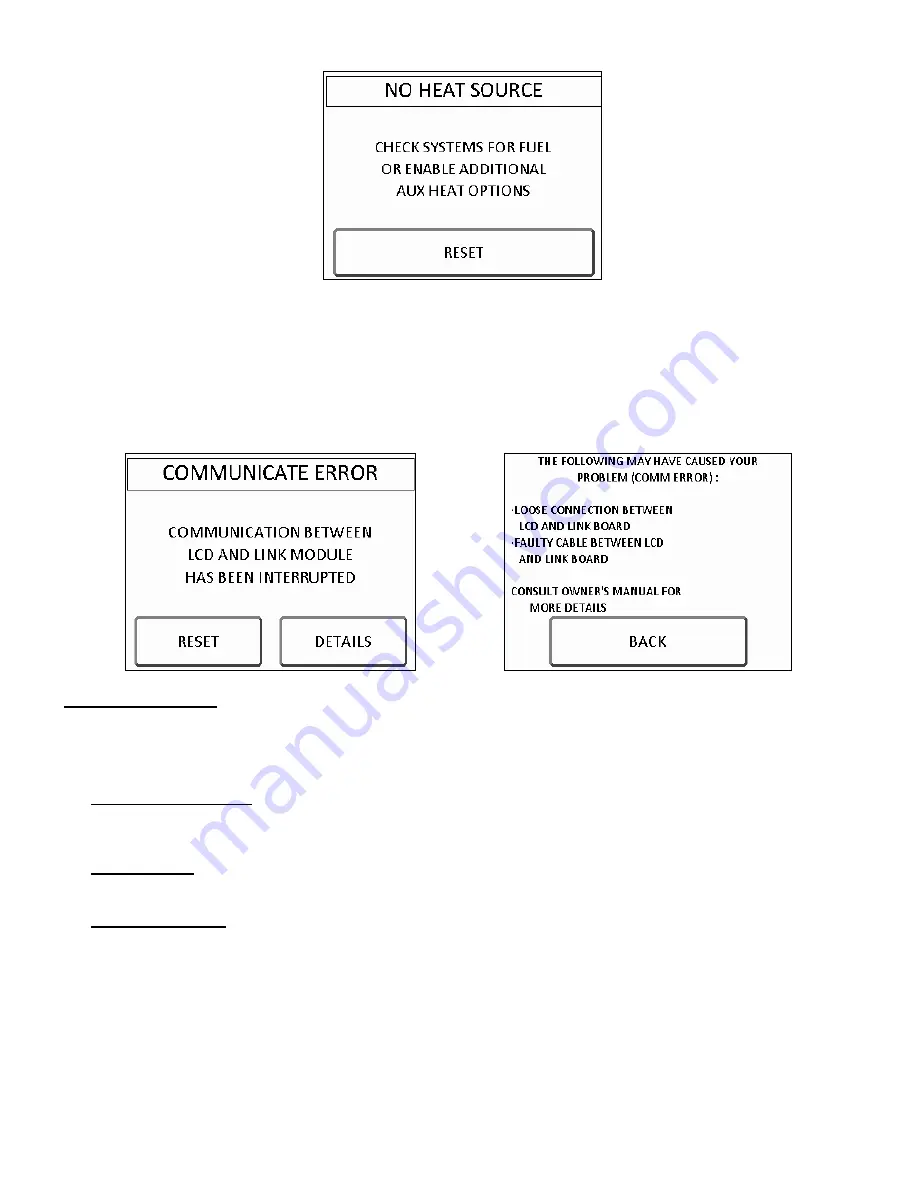

19.2.2. NO HEAT

This message appears:

•

When the wood furnace failed to raise the temperature in the plenum enough to reach the KIP or

•

When the temperature does not reach 100

̊

F in the plenum in less than five minutes for auxiliary heat.

Make sure there is a fire in the furnace or the auxiliary heating sources are functional and well connected.

19.2.3. COMMUNICATION ERROR

Communication error

: The information from the touch screen cannot be read by the link board. It is possible that the

telecommunication wire is not plugged in. Make sure each end of the wire makes good contact in the connector. It is

also possible that the wire is damaged. In this case, replace it.

19.2.4. SMOKE SMELL

•

Venting system leaks.

Inspect all vent connections. All vent connector joints must be sealed and fastened in

accordance with the vent manufacturer's instructions to ensure consistent performance and avoid smoke and ash

spillage.

•

Worn gaskets.

Gaskets may be allowing smoke spillage (doors, clean out traps, etc). Make sure that all gaskets

are in good condition and replace them with original parts if necessary. Make sure the door is well adjusted.

•

Negative pressure.

A faint wood-burning odor during ignition or shut down is normal. Although, if this increases

beyond what is considered normal or if you notice an unusual soot build-up on walls or furniture, check your

venting system carefully for leaks and make sure all gaskets are in good condition. The furnace blower produces a

negative pressure in the room. It draws air from the inside of the room, through the furnace and then outdoors. In

the same manner, other appliances can also create a larger negative pressure. In this case, as the air naturally

flows from a high pressure point to a low pressure point, a larger negative pressure can draw smoke from the

inside of the furnace into the room. The furnace can also be affected by other mechanical ventilation systems,

causing the same effect as mentioned previously. Using a fresh air intake will prevent negative pressure. Also,

make sure the recommended maintenance schedule has been followed.

Summary of Contents for PF01015

Page 10: ...10 ADD ON WOOD ONLY WOOD ELECTRIC WOOD OIL ...

Page 13: ...13 INSTALLATION AND OPERATION INSTRUCTIONS CADDY ADD ON SERIAL INSTALLATION PF01015 ...

Page 16: ...16 Option 3 Option 4 ...

Page 17: ...17 EXAMPLE 1 EXAMPLE 2 ...

Page 63: ...63 20 GENERAL ELECTRICAL DIAGRAM STANDALONE FURNACE ...

Page 64: ...64 21 ELECTRICAL DIAGRAM FOR PARALLEL FURNACE ...

Page 65: ...65 22 ELECTRICAL DIAGRAM FOR ELECTRIC UNIT ...

Page 78: ...78 31 ELECTRICAL DIAGRAM BECKETT OIL UNIT ...

Page 79: ...79 32 ELECTRICAL DIAGRAM RIELLO OIL UNIT ...

Page 81: ...81 33 4 AIR CONDITIONNING DAMPER 33 5 HUMIDIFIER 33 6 HEAT PUMP ...

Page 82: ...82 34 EXPLODED VIEW AND PART LIST ...

Page 83: ...83 ...

Page 84: ...84 ...

Page 85: ...85 ...

Page 86: ...86 ...

Page 87: ...87 ...

Page 88: ...88 ...

Page 89: ...89 ...