57

17.2. CHIMNEY MAINTENANCE

The most efficient way to sweep a chimney is to run a hard chimney sweeping brush. Brush from the top down so

sooth and creosote deposits will detach from the chimney liner and fall down to the bottom of the chimney where it can

be easily removed.

The chimney must be inspected regularly and any creosote build-up must be removed without delay. Monthly cleaning

should be sufficient during cold winter months while more frequent cleaning could be required during milder periods.

17.3. SMOKE PIPE INSPECTION

•

The smoke pipe must be inspected regularly during the heating season.

•

The pipe must be examined carefully to detect any defect or damage.

•

The pipe can be reassembled if no defect is detected and defective pipe must be replaced immediately.

•

Burn wood only in this furnace.

•

As a combustible, well seasoned hardwood in 18" logs works best.

.

17.4. BLOWER MOTOR MAINTENANCE

Periodic cleaning of the fan housing as well as fan and fan blades using a vacuum cleaner is necessary in order not to

affect performance and cause overheating of the latter.

DO NOT OVERLUBRICATE

17.5. FILTERS

Never use the furnace without air filters. To function as expected, controlled combustion wood burning appliance must

be maintained on a regular basis. This means that the chimney, the gaskets and the pipes must be kept in good

working order and the air filter cleaned or replaced regularly. Use the same size and type of filter as the original.

17.5.1. AIR FILTER DIMENSIONS

25 X 14 Filter (Caddy) #21367

17.6. DOOR GASKET MAINTENANCE

It is important to maintain the door gasket in good condition. After a while, the gasket might sag; a door adjustment

may then be required. If the door adjustment is not sufficient, replace the door gasket with a genuine one.

17.6.1. DOOR ADJUSTMENT PROCEDURE

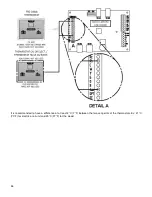

1. Unscrew completely the locking pin (see picture below).

2. To increase the pressure of the door on the gasket, turn the handle counter clockwise; to decrease the pressure of

the door on the gasket, turn the handle clockwise until desired pressure is attained.

3. Then, screw back the locking pin about 1/4" deep and make sure you lock it in place with the nut.

Locking pin

Summary of Contents for PF01015

Page 10: ...10 ADD ON WOOD ONLY WOOD ELECTRIC WOOD OIL ...

Page 13: ...13 INSTALLATION AND OPERATION INSTRUCTIONS CADDY ADD ON SERIAL INSTALLATION PF01015 ...

Page 16: ...16 Option 3 Option 4 ...

Page 17: ...17 EXAMPLE 1 EXAMPLE 2 ...

Page 63: ...63 20 GENERAL ELECTRICAL DIAGRAM STANDALONE FURNACE ...

Page 64: ...64 21 ELECTRICAL DIAGRAM FOR PARALLEL FURNACE ...

Page 65: ...65 22 ELECTRICAL DIAGRAM FOR ELECTRIC UNIT ...

Page 78: ...78 31 ELECTRICAL DIAGRAM BECKETT OIL UNIT ...

Page 79: ...79 32 ELECTRICAL DIAGRAM RIELLO OIL UNIT ...

Page 81: ...81 33 4 AIR CONDITIONNING DAMPER 33 5 HUMIDIFIER 33 6 HEAT PUMP ...

Page 82: ...82 34 EXPLODED VIEW AND PART LIST ...

Page 83: ...83 ...

Page 84: ...84 ...

Page 85: ...85 ...

Page 86: ...86 ...

Page 87: ...87 ...

Page 88: ...88 ...

Page 89: ...89 ...