PN B05577AC

B-4

Sample Handling

Liquid Sample Dispersion

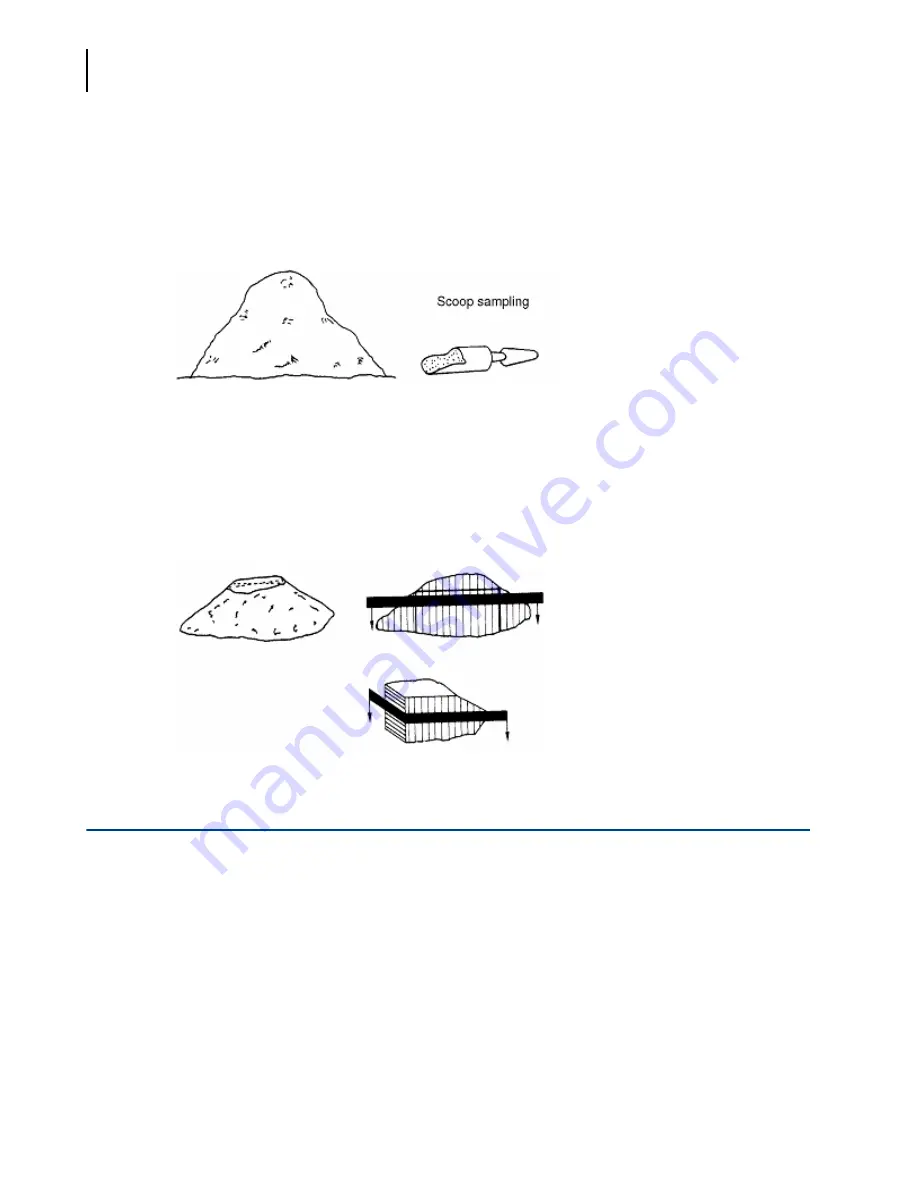

Scoop sampling

This technique is prone to error since the whole sample does not pass through the sampling device.

Sample is taken from the surface, where it may not be typical of the bulk. To eliminate segregation,

it is usual to shake the sample in a container using different modes of shaking.

Figure B.4

Figure 4. Scoop Sampling

Cone and quartering

Cone and quartering consists of pouring the material into a conical heap and hoping that all four

parts are symmetrical. If symmetry does not exist in the cutting and flattening of the heap, size

error will occur. This method is greatly dependent on the skill of the operator and consequently

should not be used.

Figure B.5

Figure 5. Cone and Quartering

Liquid Sample Dispersion

Dispersion can make or break the analysis regardless of the particle analyzer being used in the

experiment. It allows us to see the correct particle distribution for a given sample. Factors that

govern the dispersion method that is to be utilized are:

•

Solubility (e.g., fertilizer)

•

Reactivity (e.g., cement, lithium hydride with water)

•

Suspendibility (e.g., use of glycerol)

•

End use (e.g., pigments, flour)

Summary of Contents for LS 13 320

Page 4: ...PN B05577AC iv Revision History ...

Page 12: ...PN B05577AC xii Safety Notice Scope of Manual ...

Page 30: ...PN B05577AC xxx LS 13 320 Introduction System Components ...

Page 57: ...PN B05577AC 2 21 Installation Making Measurements 2 Figure 2 18 Run Cycle Options Dialog ...

Page 59: ...PN B05577AC 3 1 CHAPTER 3 LS 13 320 Software Figure 3 1 LS 13 320 Software ...

Page 80: ...PN B05577AC 3 22 LS 13 320 Software Preference Options ...

Page 86: ...PN B05577AC 3 28 LS 13 320 Software Preference Options ...

Page 116: ...PN B05577AC 4 10 Regulatory Compliance 21 CFR Part 11 Starting Security Enabled Software ...

Page 169: ...PN B05577AC 6 39 Sample Modules Micro Liquid Module 6 Figure 6 27 SOM List Dialog ...

Page 216: ...PN B05577AC 6 86 Sample Modules Universal Liquid Module ...

Page 228: ...PN B05577AC B 10 Sample Handling Diluent Selection ...

Page 238: ...PN B05577AC C 10 Optical Models Statistics ...

Page 252: ...PN B05577AC Warranty 2 Beckman Coulter Inc Customer End User License Agreement ...

Page 253: ......