Installation

Agilent

8169A

Polarization Controller, Second Edition

105

GPIB Interface

You can connect your GPIB interface into a star network, a linear network,

or a combination star and linear network. The limitations imposed on this

network are as follows:

• The total cable length cannot exceed 20 meters

• The maximum cable length per device is 2 meters

• No more than 15 devices may be interconnected on one bus.

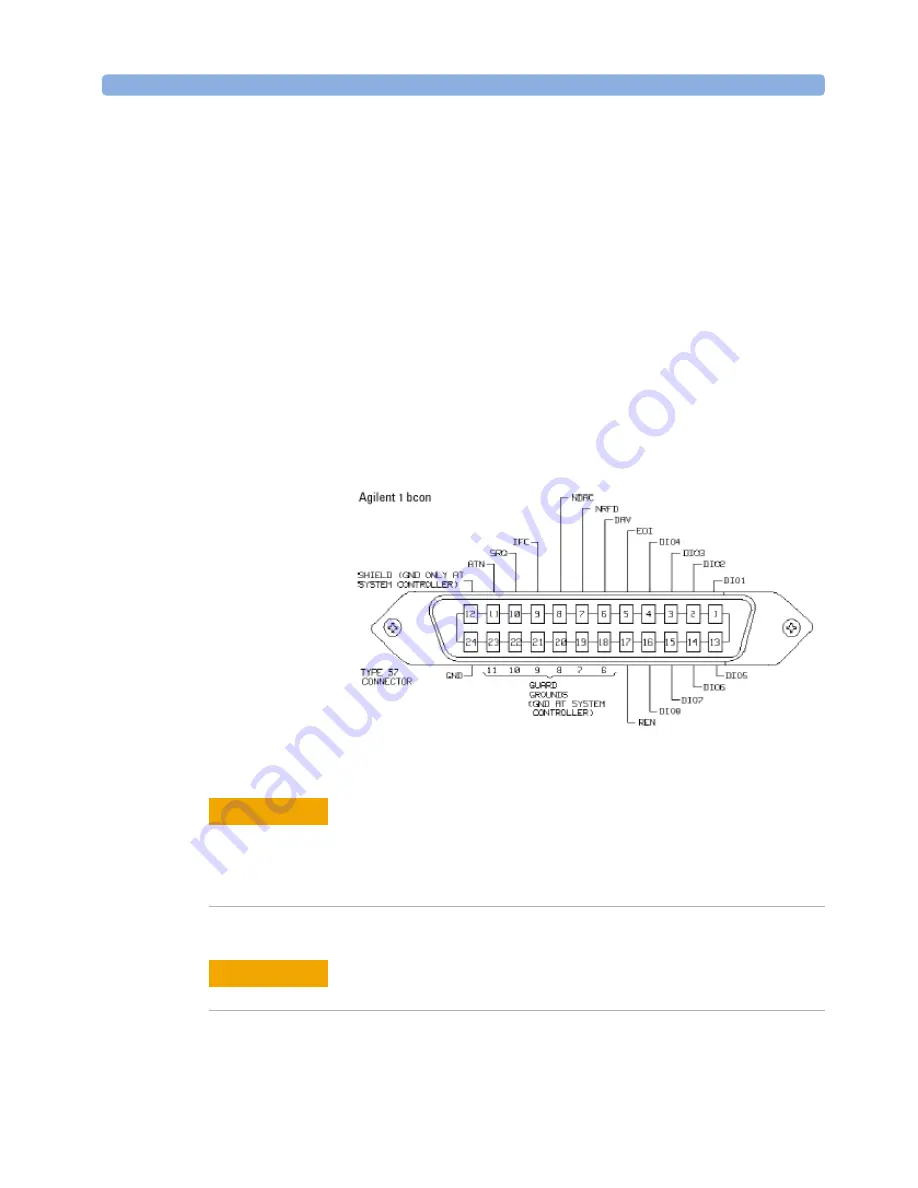

Connector

The following figure shows the connector and pin assignments. Connector

Part Number: 1251-0293

Figure 22 GPIB Connector

Agilent products delivered now are equipped with connectors

having ISO metric- threaded lock screws and stud mounts (ISO

M3.5x0.6) that are black in color. Earlier connectors may have lock

screws and stud mounts with imperial-threaded lock screws and

stud mounts (6-32 UNC) that have a shiny nickel finish.

C A U T I O N

It is recommended that you do not stack more than three

connectors, one on top of the other.

C A U T I O N