94

3D Systems, Inc

.

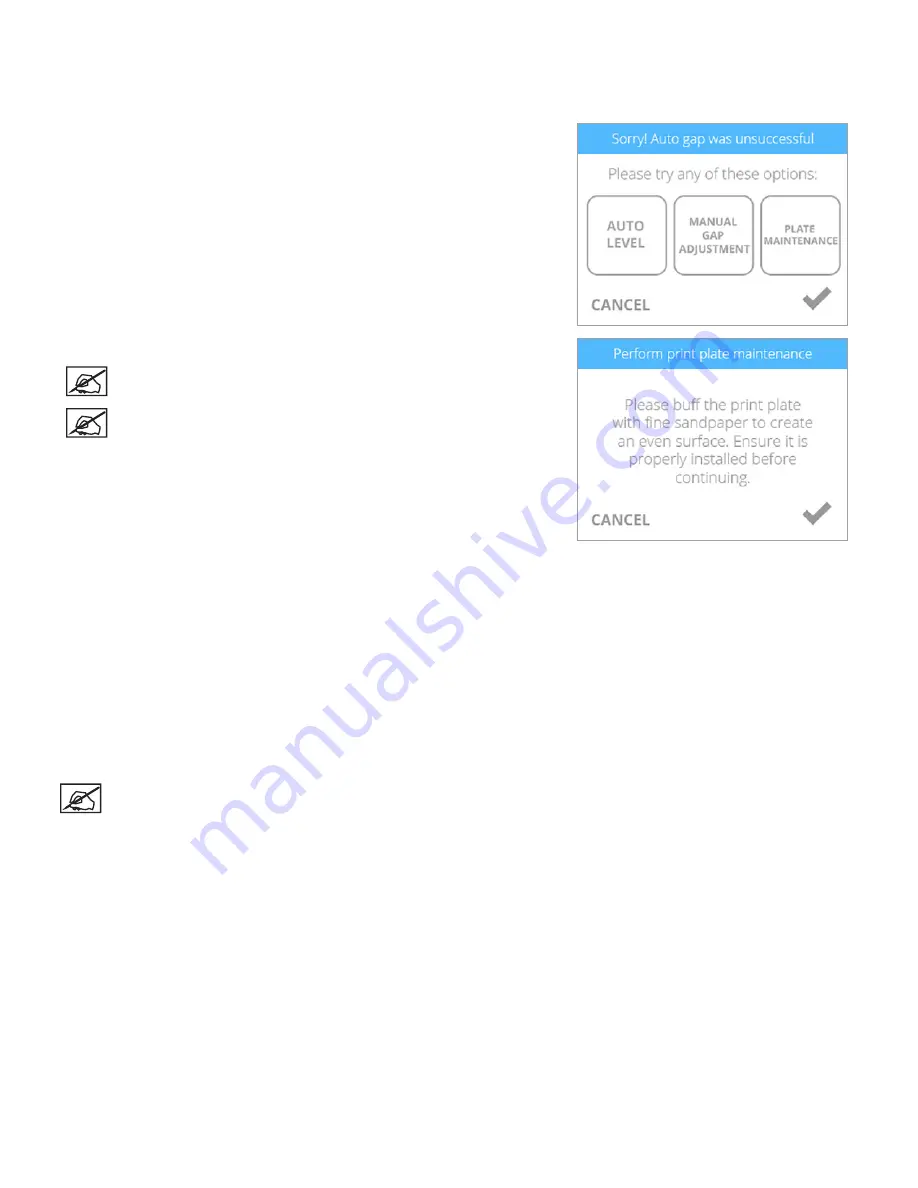

PRINT PAD MAINTENANCE

Auto Level and Auto Gap can be affected by residual glue or print material adhered to the print pad . The procedures can also be

affected by a print pad that is too shiny .

1 . If Auto Gap is unsuccessful after two consecutive attempts, select

PLATE

MAINTENANCE

.

2 .

Using the fine-grit sandpaper included with the printer, buff the print pad.

NOTE: Refer to the section titled Clean The Print Pad for specific

instructions .

NOTE: Ensure the print pad is clean and dry before installing it in

the printer .

3 . Select the

checkmark

to continue .

4 . Perform the Auto Level and Auto Gap procedures .

Clean The Print Pad

1 . Remove the print pad from the printer .

2 . Wash all glue and print material from the print pad with warm tap water . If necessary, scrub the print pad with a soft brush .

3 . Dry the print pad thoroughly .

4 . If residual material is still adhered to the print pad, gently use the scraper to remove it .

5 . If portions of the print pad appear shiny, buff the surface (with very light pressure on the included sandpaper) left-to-right in .5”

(12 .7 mm) swirling motions until the entire print pad has been treated .

NOTE: It is most important to lightly sand all shiny areas of the print pad so the print pad surface appears matte

in texture .

6 . Clean and dry the print pad thoroughly .

7 . Reinstall the print pad .

8 . Perform the Auto Level and Auto Gap procedures .

Summary of Contents for CUBE

Page 1: ...Cube Personal 3D Printer User Guide Original Instructions 3rd Generation ...

Page 59: ...55 3D Systems Inc Information Select Information A to view the printer status A ...

Page 72: ...68 3D Systems Inc Change Views Select Change Views and then select the camera viewing angle ...

Page 78: ...74 3D Systems Inc 1 Select an item from My Shelf 2 Select Print Now ...