21

3D Systems, Inc

.

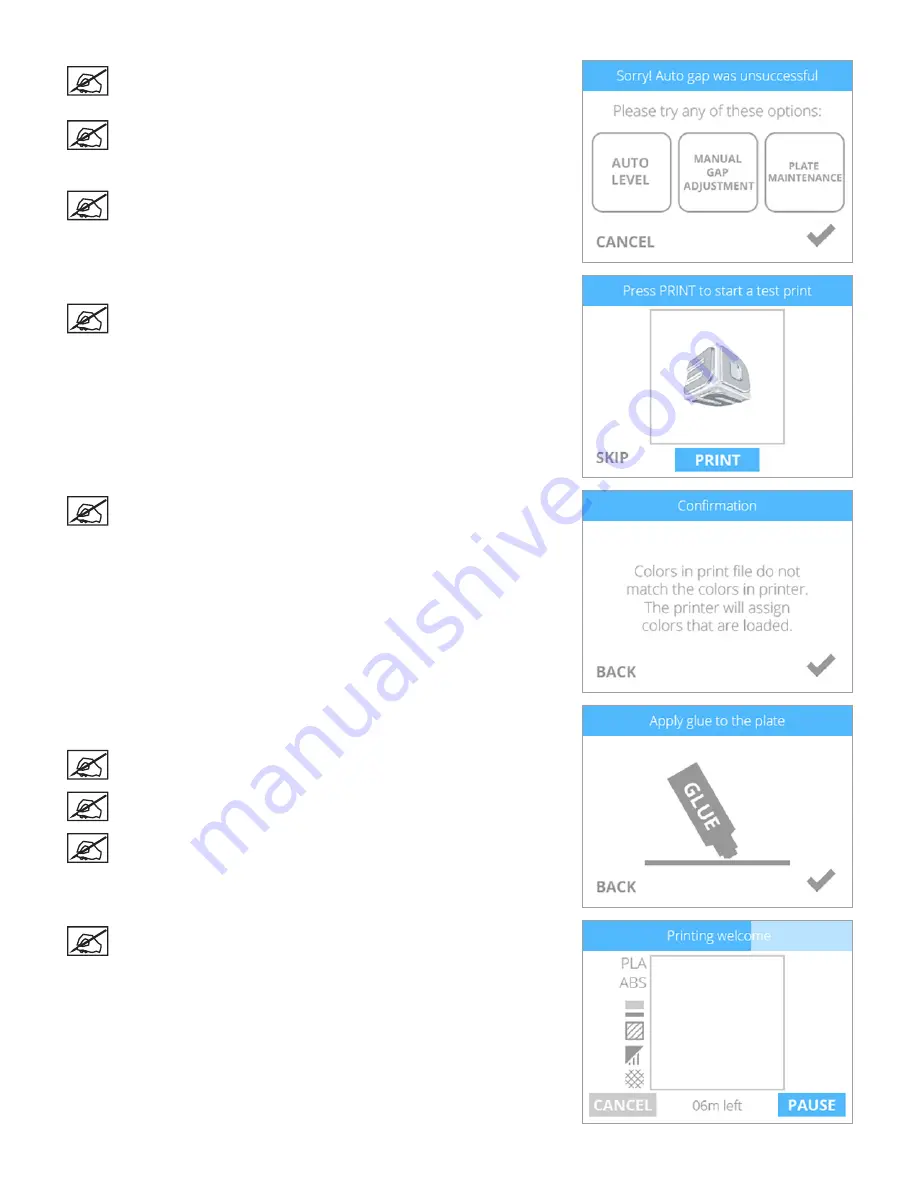

NOTE: If Auto Gap is not successful, it is recommended that you

perform Auto Level and Auto Gap again . Select

AUTO LEVEL

to

continue .

NOTE: If Auto Gap is not successful the second time, select

PLATE

MAINTENANCE

. For more information, refer to the section titled

Print Pad Maintenance . Once the Plate Maintenance procedure has

been performed, perform Auto Level and Auto Gap .

NOTE: If Auto Gap is still not successful, select

MANUAL GAP

ADJUSTMENT

. Refer to the section titled Manual Gap Adjustment for

more information . Once the Manual Gap Adjustment procedure has

been performed, note the final reading for future reference.

4 . Select

.

NOTE: The printer will continue the process of printing the welcome

message test print . Select

SKIP

to bypass this test print . You can

print this test print at any time . Navigate to the System 1 screen and

select

TEST PRINT

. Follow the prompts in the touchscreen display .

NOTE: If the color built into the test print does not match a color

of one of the installed print cartridges, the printer will assign an

installed cartridge color to the test print . Select the

checkmark

to

continue .

5 . Gently squeeze the bottle and apply two thin layers of Cube Glue to the print

pad . Select the

checkmark

to continue .

NOTE: For more information about applying glue to the print pad,

refer to the section titled Applying Cube Glue .

NOTE: Apply enough glue to cover a square area of 5” (15 cm) .

NOTE: For best results, allow the glue to dry prior to printing .

NOTE: The printer will begin to heat and then begin printing the

welcome message test print .

Summary of Contents for CUBE

Page 1: ...Cube Personal 3D Printer User Guide Original Instructions 3rd Generation ...

Page 59: ...55 3D Systems Inc Information Select Information A to view the printer status A ...

Page 72: ...68 3D Systems Inc Change Views Select Change Views and then select the camera viewing angle ...

Page 78: ...74 3D Systems Inc 1 Select an item from My Shelf 2 Select Print Now ...