76

CHAPTER2 PROFIBUS Unit

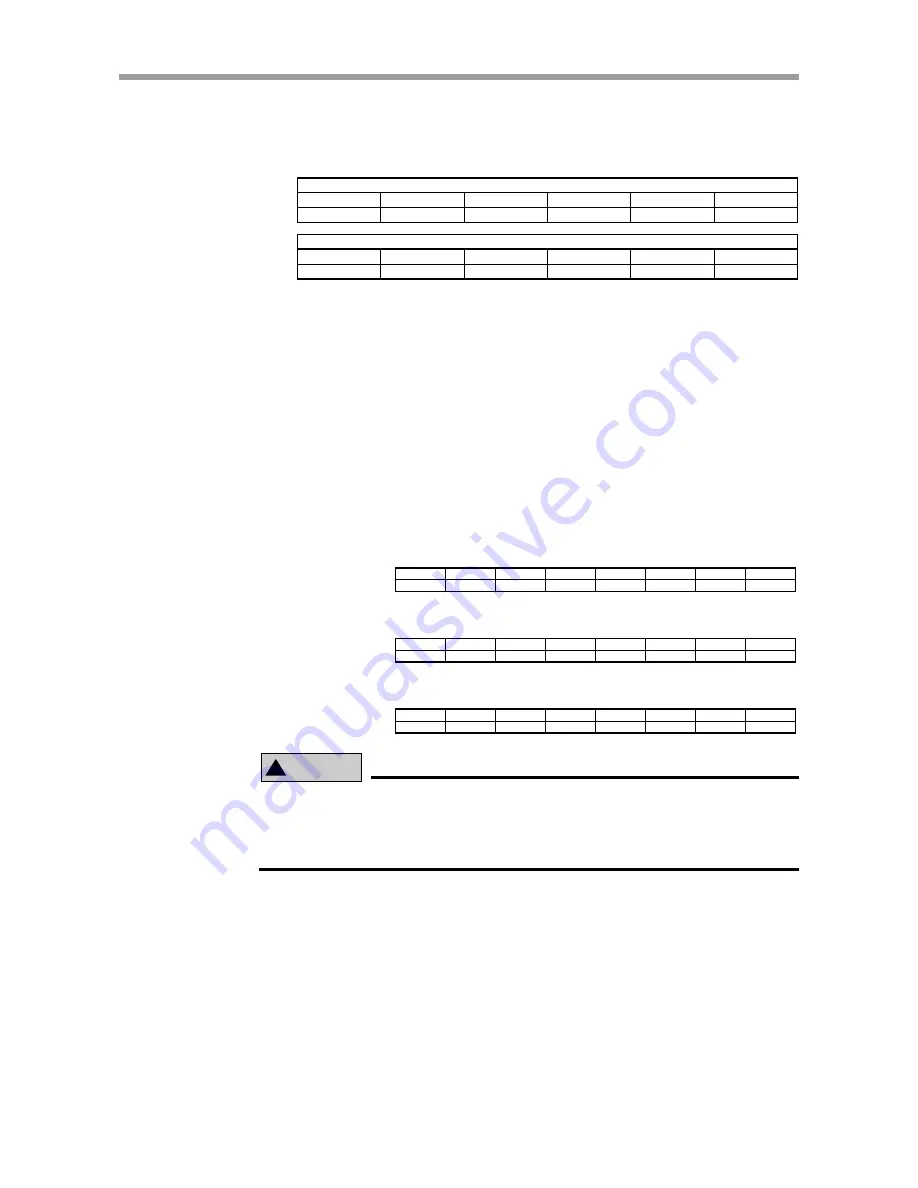

(10) Movement stroke specification

movement execution ............................................................. Code 010A

The specified axis moves from the current position by the data of the point number

specified.

Command option

QWn+22

QWn+20

QWn+18

QWn+16

QWn+14 QWn+12

Speed

Point number

Axis

Command response

IWm+22

IWm+20

IWm+18

IWm+16

IWm+14 IWm+12

(Details)

Axis:

0 means all axes, 1 means X axis and 2 means Y axis. On dual-axis

controllers, all axes are also specified when 3 is set.

On single-axis controllers, 0 or 1 alone can be specified.

Point number:

This is the inherent number assigned to each of 1000 points as a

total from 0 to 999. To specify the point variable P, register 4095

(=0FFF (hexadecimal)).

Speed:

It can be set at 100 intervals from 1 to 100, and 100=3000rpm if

the program execution speed parameter*

1

is set to 100. (In this

case, the maximum speed setting parameter*

2

is set to 3000.)

(Example)

Transmission example 1:

It moves from the current position by the P123 stroke alone at the

speed 100%.

QWn+22 QWn+20 QWn+18 QWn+16 QWn+14 QWn+12 QWn+10

QWn+8

0000

0000

0000

0064

007B

0000

0000

010A

Response example 1:

It is normally ended.

IWm+22

IWm+20

IWm+18

IWm+16

IWm+14 IWm+12 IWm+10

IWm+8

0000

0000

0000

0000

0000

0000

0000

0200

Response example 2:

The software limit over occurs.

IWm+22

IWm+20

IWm+18

IWm+16

IWm+14 IWm+12 IWm+10

IWm+8

0000

0000

0000

0000

0000

0000

0000

401E

!

CAUTION

Since the current position on the program does not vary if the movement is in-

terrupted due to the stop (interlock), etc., the movement can be continued by

executing the command again. However, if resetting is executed, the current po-

sition on the program will be initialized at the position of the robot.

*1: Single-axis controllers: PRM30, dual-axis controllers: PRM17

*2: Single-axis controllers: PRM44, dual-axis controllers: PRM64 and PRM104