74

CHAPTER2 PROFIBUS Unit

(8)

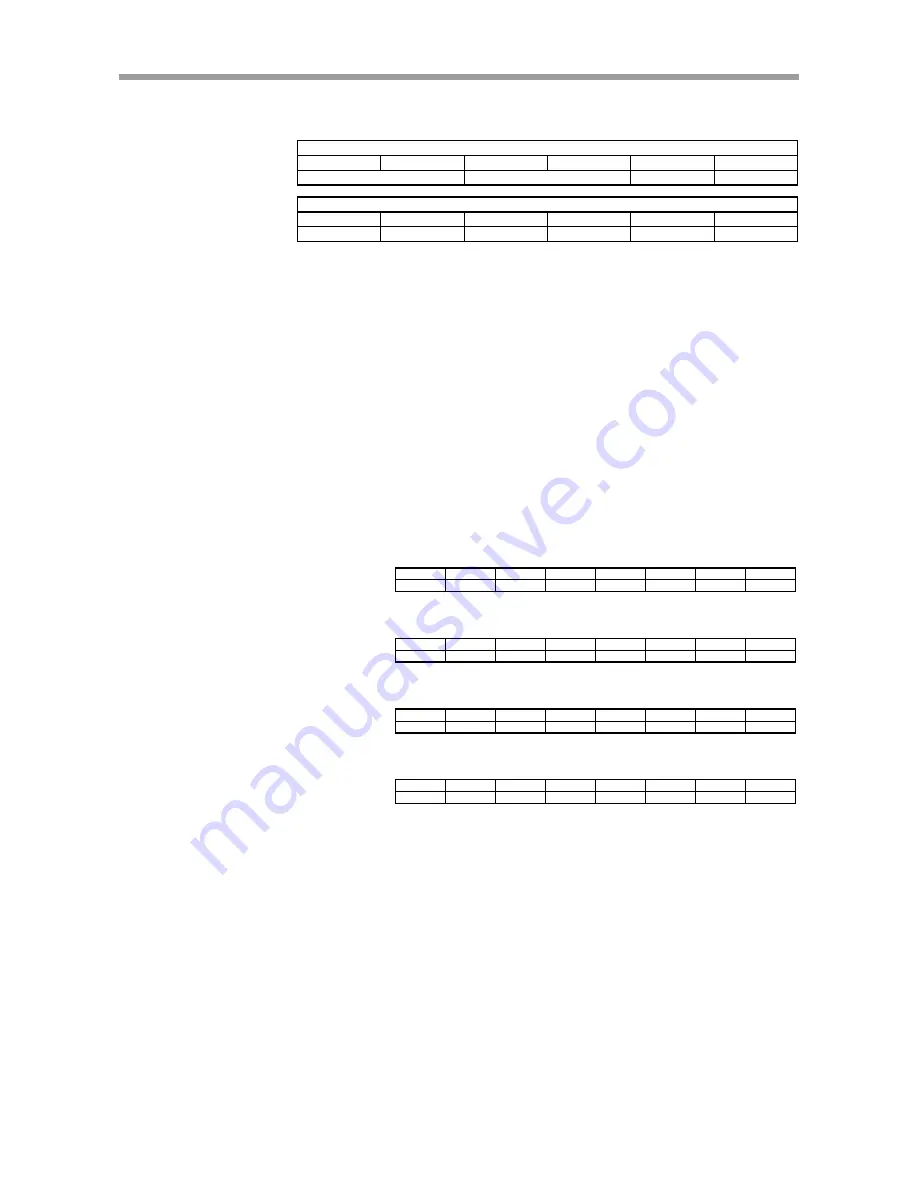

Direct position specification movement execution ............ Code 0108

It moves to the specified coordinate position.

Command option

QWn+22

QWn+20

QWn+18

QWn+16

QWn+14 QWn+12

Y axis position

X axis position

Speed

Axis

Command response

IWm+22

IWm+20

IWm+18

IWm+16

IWm+14 IWm+12

(Details)

Axis:

0 means all axes, 1 means X axis and 2 means Y axis. On dual-axis

controllers, all axes are also specified when 3 is set.

On single-axis controllers, 0 or 1 alone can be specified.

Speed:

It can be set at 100 intervals from 1 to 100, and 100=3000rpm if

the program execution speed parameter*

1

is set to 100. (In this

case, the maximum speed setting parameter*

2

is set to 3000.)

Axis position:

The desired movement position is directly specified (unit: 0.01mm).

When the robot is set at the rotary axis, the unit of the movement

position is 0.01 degrees. When the axis is specified, the axis data

is free for any other axis not specified. Similarly, it does not matter

that the data of Y axis is free on single-axis controllers.

(Example)

Transmission example 1:

In the current position indication mode, it moves to the position of

X=50.37 and Y=45.55 at the 100% speed.

QWn+22 QWn+20 QWn+18 QWn+16 QWn+14 QWn+12 QWn+10

QWn+8

0000

11CB

0000

13AD

0064 0000 0001 0108

Response example 1:

It is normally ended.

IWm+22

IWm+20

IWm+18

IWm+16

IWm+14 IWm+12 IWm+10

IWm+8

0000

11CB

0000

13AD

0000 0000 0000 0200

Transmission example 2:

It moves to the position of Y=850.00 at the 50% speed.

QWn+22 QWn+20 QWn+18 QWn+16 QWn+14 QWn+12 QWn+10

QWn+8

0001

4C08

0000

0000

0032 0002 0000 0108

Response example 2:

The software limit over occurs.

IWm+22

IWm+20

IWm+18

IWm+16

IWm+14 IWm+12 IWm+10

IWm+8

0000

0000

0000

0000

0000 0000 0000 401E

*1: Single-axis controllers: PRM30, dual-axis controllers: PRM17

*2: Single-axis controllers: PRM44, dual-axis controllers: PRM64 and PRM104