15

CHAPTER2 PROFIBUS Unit

2-7

I/O information

On/off (I/O) information handled by the PROFIBUS unit consists of 16 dedicated in-

puts, 32 general-purpose I/O inputs, 16 dedicated outputs and 32 general-purpose out-

puts.

Dedicated inputs are sub-grouped by assigned function into 13 dedicated command in-

puts, interlock, service mode and emergency stop inputs.

* Some ports are currently reserved for future use and not available for dedicated com-

mand input and dedicated outputs.

* PROFIBUS I/O functions and methods for using them are basically identical to those

for the parallel I/O that are a standard feature in the controller.

2-7-1

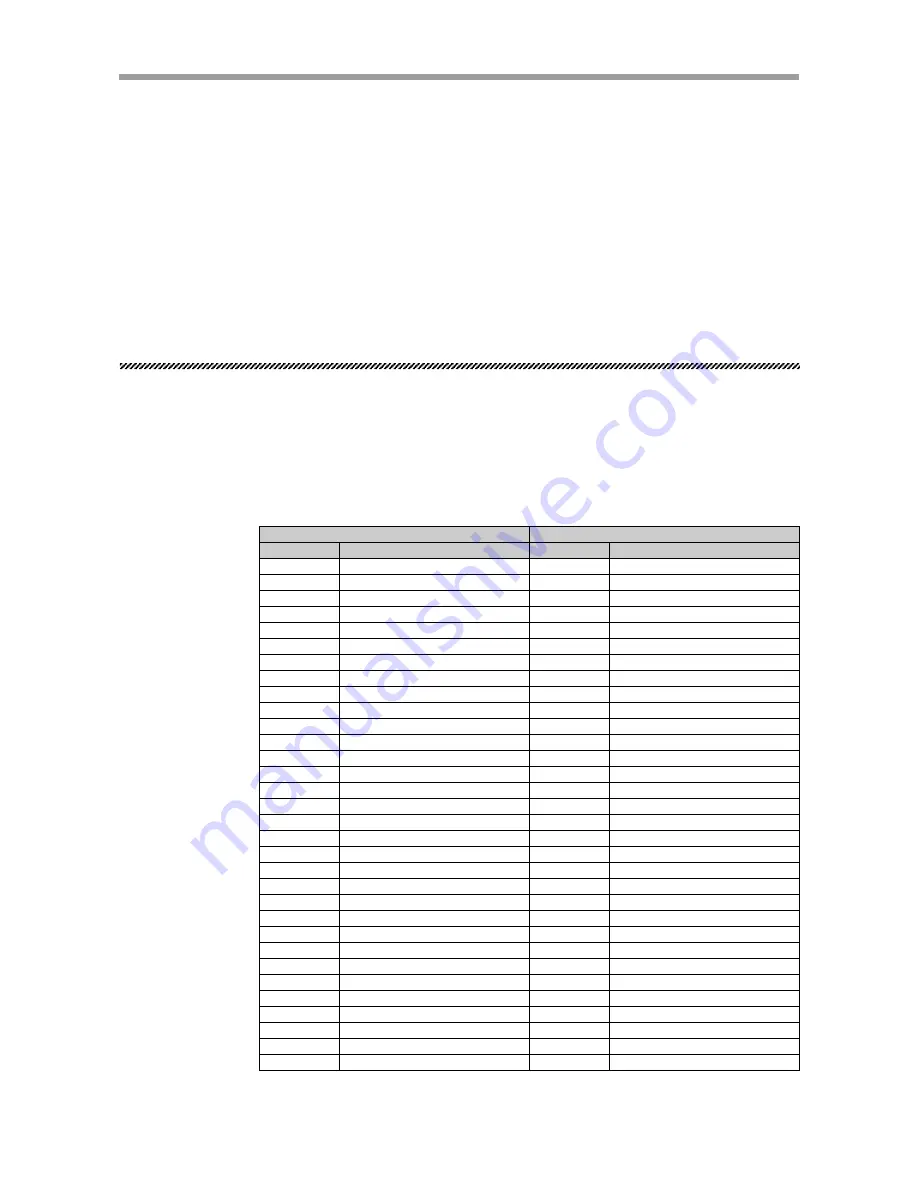

Profile (I/O signal table)

The following table is a list profiling the PROFIBUS unit.

More detailed information on each signal is listed in “2-7-2 Dedicated command in-

puts”.

Remote I/O signals (Bit I/O)

Servo status (SRV-O)

(ZONE 0)

(ZONE 1)

(ZONE 2)

(ZONE 3)

Reserved

Origin return status (ORG-O)

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

END

BUSY (executing command)

READY

SO200

SO201

SO202

SO203

SO204

SO205

SO206

SO207

SO208

SO209

SO210

SO211

SO212

SO213

SO214

SO215

Im.0

Im.1

Im.2

Im.3

Im.4

Im.5

Im.6

Im.7

Im+1.0

Im+1.1

Im+1.2

Im+1.3

Im+1.4

Im+1.5

Im+1.6

Im+1.7

Im+2.0

Im+2.1

Im+2.2

Im+2.3

Im+2.4

Im+2.5

Im+2.6

Im+2.7

Im+3.0

Im+3.1

Im+3.2

Im+3.3

Im+3.4

Im+3.5

Im+3.6

Im+3.7

SERVO (servo recovery)

INC-PT (move relative point)

ABS-PT (move absolute point)

STEP-R (step operation)

AUTO-R (auto operation)

RESET

ORG-S (origin return)

LOCK (interlock)

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

SVCE (service mode)

EMG (emergency stop input)

SI200

SI201

SI202

SI203

SI204

SI205

SI206

SI207

SI208

SI209

SI210

SI211

SI212

SI213

SI214

SI215

Qn.0

Qn.1

Qn.2

Qn.3

Qn.4

Qn.5

Qn.6

Qn.7

Qn+1.0

Qn+1.1

Qn+1.2

Qn+1.3

Qn+1.4

Qn+1.5

Qn+1.6

Qn+1.7

Qn+2.0

Qn+2.1

Qn+2.2

Qn+2.3

Qn+2.4

Qn+2.5

Qn+2.6

Qn+2.7

Qn+3.0

Qn+3.1

Qn+3.2

Qn+3.3

Qn+3.4

Qn+3.5

Qn+3.6

Qn+3.7

OUTPUT (Slave

→

Master)

INPUT (Master

→

Slave)

Address

Signal Name

Address

Signal Name