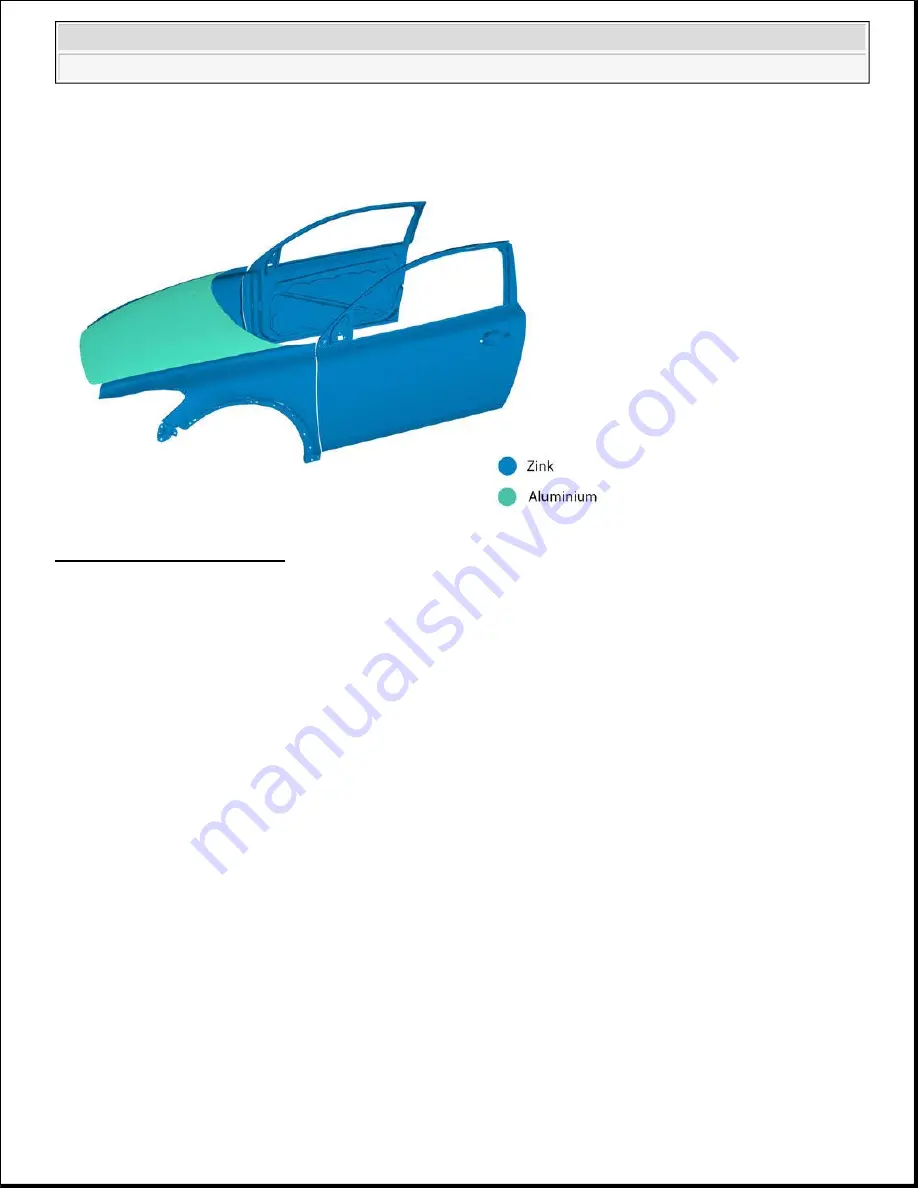

Fig. 13: Identifying Zinc Area

Courtesy of VOLVO CARS CORPORATION

HSS (High Strength Steel) is a general term for steel material within a specific strength range.

The vehicles are built of different steel material, partly to optimize the body (impact safety, rigidity, fuel

economy, etc.) and partly to make it as repair-friendly as possible. The steel material is classified into four

different groups based on tensile strength, which is the force required to plastically deform the material.

Mild steel (MS). Trade steel with highest tensile strength of 180 MPa.

High tensile strength steels (HS). Steel with a tensile strength between 180 - 280 MPa.

Very high tensile strength steels (VHS). Steel with a tensile strength between 280 - 380 MPa.

Extra high tensile strength steels (EHS). Steel with a tensile strength between 380 - 800 MPa.

Ultra High Strength steel (UHS). Steel with a tensile strength of more than 800 MPa.

Mild Steel. This category of steel is used where use of a stronger steel is not necessary.

High Strength Steel There are three main types of steel in this category:

Phosphorus-alloyed steel obtains is increase in strength with the help of the alloy matter phosphorus.

HSLA steel (High Strength Low Alloy) is a low alloy steel in which the steel obtains its increase in

CAUTION: HSS material must not be heated via gas welding or the like.

2012 Volvo C30 T-5

ACCESSORIES AND BODY, CAB Body Frame - General Information