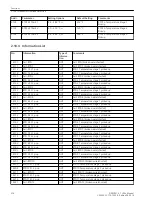

Output of Results

The hot-spot temperature is calculated for the winding which corresponds to the side of the protected object

configured for overload protection (Section

2.1.4.3 Assignment of Protection Functions to Measuring Loca-

, margin heading “Further 3-phase Protection Functions”, address 442). The calculation includes

the current of that side and the cooling temperature measured at a certain measuring point. The phase infor-

mation is taken from the concerned phase in case of generators, motors, etc., or wye- or zigzag-connected

transformer windings; in case of delta-connected transformer windings the phase-difference currents are deci-

sive which correspond to the current flowing in the winding.

There are two thresholds which can be set. They output a warning (Stage 1) and an alarm (Stage 2) signal.

When the alarm signal is assigned to a trip output, it can also be used for tripping the circuit breaker(s).

For the middle ageing rate, there is also a threshold for each of the warning and the alarm signal.

The status can be read out from the operational measured values at any time. The information includes:

•

hot-spot temperature for each winding in °C or °F (as configured),

•

relative ageing rate expressed in per unit,

•

load backup up to warning signal (Stage 1) expressed in per cent,

•

load backup up to alarm signal (Stage 2) expressed in per cent.

Further limit values can be set on the thermobox itself, as in Section “RTD-Boxes for Overload Recognition”

Setting Notes

General

i

i

NOTE

The first thermal overload protection is described in the setting instructions. The parameter addresses and

message numbers of the second thermal overload protection are described at the end of the setting

instructions under “Additional Thermal Overload Protection Functions”.

The overload protection can be assigned to any desired side of the protected object. Since the cause of the

overload current is outside the protected object, the overload current is a through-flowing current, the over-

load protection may be assigned to a feeding or a non-feeding side. When setting the assignment of the

protection functions to the sides of the protected object according to Section

2.1.4.3 Assignment of Protection

Functions to Measuring Locations / Sides

, margin heading “Further 3-Phase Protection functions”, you have

performed this assignment under address 442

THERM. O/L AT

. Respective notes are given here.

Three methods are available for overload detection, as set out above. During configuration of the functional

scope (Section

) it was set under address 142

THERM. OVERLOAD

whether the overload

protection must function according to the thermal replica (

THERM. OVERLOAD

=

th rep w.o. sen

), if

necessary, under inclusion of the environmental or coolant temperature (THERM. OVERLOAD = th repl w. sens)

or whether the hot-spot calculation according to IEC 60354 must be executed (

THERM. OVERLOAD

=

IEC354

). In the latter two cases, at least one RTD-box 7XV5662-xAD must be connected to the device in order

to digitally inform the device about the coolant temperature. The required data for the RTD-box were set

under address 191

RTD CONNECTION

(Section

Under address 4201

THERM. OVERLOAD

overload protection

ON

or

OFF

can be set. If address 142

THERM.

OVERLOAD

has been set to

th rep w.o. sen

during configuration of the functional scope, the setting

Alarm Only

is also possible. With that latter setting the protection function is active but only outputs an

alarm when the tripping temperature rise is reached, i.e. the output function

ThOverload TRIP

is not

active. The option

Block relay

allows to operate the protection but the trip output relay is blocked.

k-Factor

The rated current of the side of the main protected object which is assigned to the overload protection is taken

as the base current for detecting an overload. The setting factor k is set in address 4202

K-FACTOR

. It is deter-

mined by the relation between the permissible thermal continuous current and this rated current:

2.9.5

Functions

2.9 Thermal Overload Protection

SIPROTEC 4, 7UT6x, Manual

205

C53000-G1176-C230-5, Edition 09.2016

Содержание SIPROTEC 4 7UT6 Series

Страница 394: ...394 SIPROTEC 4 7UT6x Manual C53000 G1176 C230 5 Edition 09 2016 ...

Страница 482: ...482 SIPROTEC 4 7UT6x Manual C53000 G1176 C230 5 Edition 09 2016 ...

Страница 504: ...504 SIPROTEC 4 7UT6x Manual C53000 G1176 C230 5 Edition 09 2016 ...

Страница 522: ...522 SIPROTEC 4 7UT6x Manual C53000 G1176 C230 5 Edition 09 2016 ...

Страница 528: ...528 SIPROTEC 4 7UT6x Manual C53000 G1176 C230 5 Edition 09 2016 ...

Страница 538: ...538 SIPROTEC 4 7UT6x Manual C53000 G1176 C230 5 Edition 09 2016 ...

Страница 664: ...664 SIPROTEC 4 7UT6x Manual C53000 G1176 C230 5 Edition 09 2016 ...

Страница 666: ...666 SIPROTEC 4 7UT6x Manual C53000 G1176 C230 5 Edition 09 2016 ...

Страница 683: ...Z Zero sequence currents 109 Index SIPROTEC 4 7UT6x Manual 683 C53000 G1176 C230 5 Edition 09 2016 ...

Страница 684: ...684 SIPROTEC 4 7UT6x Manual C53000 G1176 C230 5 Edition 09 2016 ...