Operating

7.12 Open Channel Monitoring (OCM)

HydroRanger 200 HMI

Operating Instructions, 06/2018, A5E36281317-AC

151

7.12.5

Universal calculation support

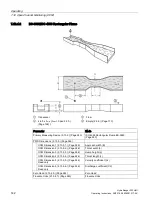

When the Primary Measuring Device (PMD) doesn’t fit one of the standard types, it can be

programmed using a universal characterization. When Primary Measuring Device (2.13.2.)

(Page 240) = Universal, then the head/flow breakpoints must be entered into Universal Head

vs. Flow (2.13.6.) (Page 247)

Two curve types are supported:

●

Universal Linear Flow Calculation (Page 240) (piece wise linear)

●

Universal Curved Flow Calculation (Page 240) (cubic spline)

Both are shown in the following chart.

7.12.6

Typical flow characterization

①

Flow

③

Curved

②

Linear

④

Head

Characterization is achieved by entering Head 1 (2.13.6.1.1.) (Page 247) and its

corresponding Flow 1 (2.13.6.1.2.) (Page 248), either from empirical measurement or from

the manufacturer's specification.

●

Increasing the number of defined breakpoints will increase the accuracy of the flow

measurement.

●

Breakpoints should be concentrated in areas exhibiting the higher degrees of nonlinear

flow. A maximum of 32 breakpoints can be defined.

●

For Universal Linear Flow Calculation, Maximum Head and Maximum Flow must be

entered as breakpoints.

●

For Universal Curved Flow Calculation, values in Maximum Head (2.13.4.2.), Maximum

Flow (2.13.4.3.) are automatically used.

Содержание HydroRanger 200 HMI

Страница 2: ......

Страница 20: ...Introduction 1 5 Notes on warranty HydroRanger 200 HMI 18 Operating Instructions 06 2018 A5E36281317 AC ...

Страница 24: ...Safety notes HydroRanger 200 HMI 22 Operating Instructions 06 2018 A5E36281317 AC ...

Страница 28: ...Description 3 5 Modbus communication HydroRanger 200 HMI 26 Operating Instructions 06 2018 A5E36281317 AC ...

Страница 159: ...Parameter reference 8 2 Parameter indexing HydroRanger 200 HMI Operating Instructions 06 2018 A5E36281317 AC 157 ...

Страница 276: ...Parameter reference 8 10 Language 6 HydroRanger 200 HMI 274 Operating Instructions 06 2018 A5E36281317 AC ...

Страница 322: ...Pump control reference B 13 Other pump controls HydroRanger 200 HMI 320 Operating Instructions 06 2018 A5E36281317 AC ...

Страница 352: ...Communications C 41 Single parameter access SPA HydroRanger 200 HMI 350 Operating Instructions 06 2018 A5E36281317 AC ...

Страница 354: ...Updating software HydroRanger 200 HMI 352 Operating Instructions 06 2018 A5E36281317 AC ...

Страница 359: ...HydroRanger 200 HMI Operating Instructions 06 2018 A5E36281317 AC 357 Conduit entry for Class I Div 2 applications F ...

Страница 360: ...Conduit entry for Class I Div 2 applications HydroRanger 200 HMI 358 Operating Instructions 06 2018 A5E36281317 AC ...

Страница 361: ...Conduit entry for Class I Div 2 applications HydroRanger 200 HMI Operating Instructions 06 2018 A5E36281317 AC 359 ...

Страница 362: ......

Страница 372: ...Programming chart G 1 Programming chart HydroRanger 200 HMI 370 Operating Instructions 06 2018 A5E36281317 AC ...

Страница 390: ...LCD menu structure H 1 LCD Menu Structure HydroRanger 200 HMI 388 Operating Instructions 06 2018 A5E36281317 AC ...

Страница 403: ......