62

S50A Mobile

Operator’s Manual

Maintenance programme

Carry out the following maintenance

Daily

Check for any rubber and nylon components which are damaged and need to be

replaced in order to prevent damage. Replace any worn components.

Clean all the areas in contact with rims or tyres in order to prevent any scratches

on the rims.

Weekly

Clean the tyre changer with workshop clothes or a vacuum cleaner.

Do not

use compressed air jets for cleaning, since they can eject dirt on moving

parts.

Monthly

Check all the controls to make sure that they activate the intended functions.

Grease all the moving parts.

Periodically

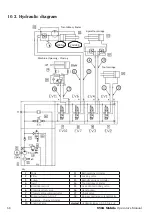

P

eriodically check the oil level of the hydraulic control unit using the designated dipstick

located on the control unit cap.

If necessary, top up with:

MANUfACTURER OIL TYPE

AGIP

OSO32 - ARNICA68

ESSO

NUTO32 - INVAROL EP68

FINA

HYDRAN32 - IDRAN HY68

SHELL

TELLUS OIL32 - TELLUS OIL 68

API

CIS32 - HS68

Should it be necessary to replace the control unit oil, remember that the tank is equipped

with a designated drain cap.

4.2 Spare parts

Refer to the specific spare part manual.

4.3 Gear box lubrication

The gear box of S50A Mobile tyre changer is NOT filled with “LONG LIFE” grease.

Should the grease in the gear box need to be replaced, use one of the following grease type (or a similar one):

Vanguard ML00EP; BP FG00EP; Esso Transmission Grease EP; IP Atina; Mobil Mobilplex 44; Shell Simnia 0; Total Carter

SY00.

The necessary quantity of grease is 1500 gr. (48.2 oz)

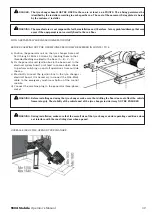

4.4 Turntable trolley check

Periodically check the turntable trolley, in order to prevent excessive clearance

between guide rails and sliding blocks and, therefore, irreversible damage to

mechanical moving parts.

If the clearance is evident, adjust the sliding blocks as described below.

ADJUSTING THE SLIDING BLOCKS

Disconnect the machine from the electric power supply.

Loosen the 4 nuts (3) fixing the upper left sliding block.

Loosen the 4 nuts fixing the lower left sliding block (4).

Loosen the 4 nuts (5) locking the adjuster on the trolley left side.

Alternately tighten the 4 screws (6) until the sliding blocks are in contact with the

guide rails.

Содержание S50A Mobile

Страница 2: ......

Страница 3: ......

Страница 36: ...36 S50A Mobile Manuale d uso Note...

Страница 37: ...S50A Mobile Manuale d uso 37 Note...

Страница 70: ...70 S50A Mobile Operator s Manual Notes...

Страница 71: ...S50A Mobile Operator s Manual 71 Notes...

Страница 104: ...104 S50A Mobile Manuel d utilisation Notes...

Страница 105: ...S50A Mobile Manuel d utilisation 105 Notes...

Страница 112: ...112 S50A Mobile Betriebsanleitung 1 4 Positionen der Aufkleber 10 AGT TILT Manuale 1 4 Posizionamento degli adesivi...

Страница 138: ...138 S50A Mobile Betriebsanleitung Anmerkungen...

Страница 139: ...S50A Mobile Betriebsanleitung 139 Anmerkungen...

Страница 146: ...146 S50A Mobile Manual de uso 1 4 Posicionamiento de los adhesivos 10 AGT TILT Manuale 1 4 Posizionamento degli adesivi...

Страница 172: ...172 S50A Mobile Manual de uso Notas...

Страница 173: ...S50A Mobile Manual de uso 173 Notas...