42

S50A Mobile

Operator’s Manual

4. To inflate the tyre, remove it from the tyre changer and place it in the inflation cage

5. It is not permitted to use inflation devices (e.g. gun) connected to the tyre changer through power sources outside the

machine.

6. Never bring your head or other body parts close to a tyre during bead insertion operation. This machine is not a safety

device against the possible risk of explosion of tyres, air chambers or rims.

7. Maintain a safe distance from the tyre changer during bead insertion operation. Do not approach it.

DANGER:

A bursting tyre can cause projections of its parts in surrounding areas with a force sufficient to cause serious

injuries or death.

Do not mount a tyre if its dimensions (indicated on the side) do not correspond exactly to the rim dimensions

(printed inside the rim) or if the rim or the tyre is defective or damaged.

The tyre changer is not a safety device and does not prevent tyres and rims from exploding. Keep bystanders at a

distance.

8. Risk of crushing. Presence of moving parts. Contact with moving parts can cause accidents.

• The machine can only be used by one operator at a time.

• Keep bystanders away from the tyre changer.

• Keep your hands and fingers away from the rim edge during the demounting and mounting process.

• Keep your hands and fingers away from the mounting tool during operation.

• Keep your hands and fingers away from the bead breaker disc during operation.

• Keep your hands and other body parts away from moving parts.

• Do not use tools other than those supplied with the tyre changer and always SICE original accessories.

• Use lubricant that is specific for tyres in order to prevent tyre seizure.

• Pay attention while handling the rim or the tyre and while using the lever

9. Danger of electric shock.

• Do not clean electric parts with water or high pressure air jets.

• Do not operate the machine in the presence of a damaged electrical cable.

• If an extension is necessary, use a cable with rated features equal to or greater than those of the

machine. Cables with rated features that are lower than those of the machine could overheat and cause

a fire.

• Make sure that the cable is positioned so that it cannot be pulled and the risk of tripping is avoided.

10. Risk of eye injuries. During the bead insertion and inflation phase, debris, dust and fluids could be projected into the air.

Remove any debris present on the tyre tread and on the tyre surface. Wear protective goggles with OSHA, CE approval

or other certified devices during all work phases.

11. Always carefully inspect the machine before using it. Missing, damaged or worn equipment (including the hazard adhesive

labels) must be repaired or replaced before start-up.

12. Never leave nuts, bolts, tools or other materials on the machine. They could be entangled in moving parts and cause

malfunctions or be ejected.

13. Do NOT mount or inflate tyres that are cut, damaged, decayed or worn. Do NOT mount tyres on damaged, bent, rusted,

worn, warped or deformed rims.

14. Should the tyre get damaged during the mounting phase, do not try to complete the mounting operation. Remove it,

take it away from the service area and mark it as damaged.

15. The internal parts in this equipment could create contacts or sparks if exposed to flammable vapours (petrol, paint

thinners, solvents, etc.). Do not install the machine in a narrow area or position it below floor level.

16. Do not operate the machine while under the influence of alcohol, medicines and/or drugs. If you are taking prescription

or non-prescription medicines, contact a physician to be aware of the side effects that they might have on the ability to

operate the machine safely.

17. Always use OSHA, CE approved and authorised personal protective equipment (PPE) or equipment with

equivalent certifications while operating the machine. Consult your supervisor for additional instructions.

18. Do not wear jewellery, watches, loose clothing, ties and tie up long hair before using the machine.

19. Wear protective, non-slip footwear while using the tyre changer.

20. While positioning, lifting or removing wheels from the tyre changer, wear an appropriate back support

and use a correct lifting technique.

21. Only appropriately trained personnel can use, service and repair the machine. Repairs must only be

performed by qualified personnel. SICE technicians are the most qualified individuals. The employer

must determine if an employee is qualified to carry out any machine repair safely if the operator has

attempted to make the repair.

Содержание S50A Mobile

Страница 2: ......

Страница 3: ......

Страница 36: ...36 S50A Mobile Manuale d uso Note...

Страница 37: ...S50A Mobile Manuale d uso 37 Note...

Страница 70: ...70 S50A Mobile Operator s Manual Notes...

Страница 71: ...S50A Mobile Operator s Manual 71 Notes...

Страница 104: ...104 S50A Mobile Manuel d utilisation Notes...

Страница 105: ...S50A Mobile Manuel d utilisation 105 Notes...

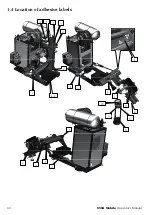

Страница 112: ...112 S50A Mobile Betriebsanleitung 1 4 Positionen der Aufkleber 10 AGT TILT Manuale 1 4 Posizionamento degli adesivi...

Страница 138: ...138 S50A Mobile Betriebsanleitung Anmerkungen...

Страница 139: ...S50A Mobile Betriebsanleitung 139 Anmerkungen...

Страница 146: ...146 S50A Mobile Manual de uso 1 4 Posicionamiento de los adhesivos 10 AGT TILT Manuale 1 4 Posizionamento degli adesivi...

Страница 172: ...172 S50A Mobile Manual de uso Notas...

Страница 173: ...S50A Mobile Manual de uso 173 Notas...